A Brief Analysis of Quick - Freezing Cold Storage Design

2025-03-12

I. What is a quick-freezing cold storage?

Quick-freezing cold storage refers to a method in which food rapidly passes through its maximum ice crystal formation zone and is quickly frozen when the average temperature reaches -18°C. During the freezing process of food, various changes will occur, such as physical changes, changes in cell tissues, as well as biological and microbial changes. Generally, the temperature of a quick-freezing cold storage is usually between -15°C and -35°C.

II. Differences among Quick-freezing Cold Storage, Refrigeration Cold Storage, and Fresh-keeping Cold Storage

In the industry, according to the different products stored and the requirements for the temperature of the cold storage, cold storages are usually classified into the following types:

Quick-freezing cold storage refers to a method in which food rapidly passes through its maximum ice crystal formation zone and is quickly frozen when the average temperature reaches -18°C. During the freezing process of food, various changes will occur, such as physical changes, changes in cell tissues, as well as biological and microbial changes. Generally, the temperature of a quick-freezing cold storage is usually between -15°C and -35°C.

II. Differences among Quick-freezing Cold Storage, Refrigeration Cold Storage, and Fresh-keeping Cold Storage

In the industry, according to the different products stored and the requirements for the temperature of the cold storage, cold storages are usually classified into the following types:

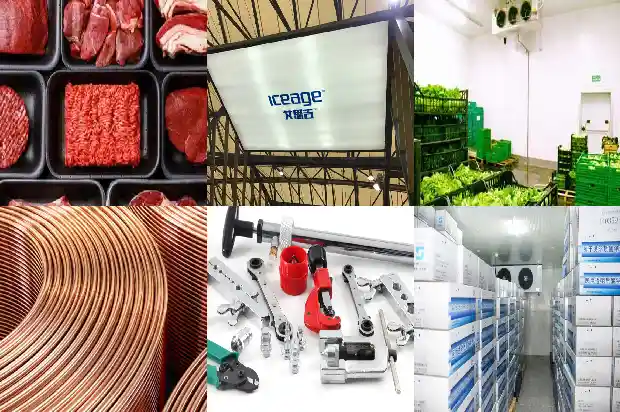

- Fresh-keeping Cold Storage:

The temperature of a fresh-keeping cold storage is generally between 0°C and 5°C, mainly used for preservation. That is, it can maintain the original quality and freshness of agricultural products to the greatest extent within a long period of time. The living bodies of agricultural products should not die as much as possible, and the cells are in a dormant state during the refrigeration process, reducing the loss of nutrients and maintaining a fresh quality. This is generally applied to fruits and vegetables. In the current fruit and vegetable industry, they are all intensively planted. In the processes of transportation, sale, etc., it is inevitable to use cold storages to maintain the necessary nutritional components of fruits and vegetables. - Refrigeration Cold Storage:

The temperature of a refrigeration cold storage is generally between -15°C and -18°C. Generally, food is gradually put into the cold storage irregularly. After a certain period of time, the temperature of the cold storage reaches -18°C, and the goods are taken out irregularly and at irregular times. There is no specific requirement for this "certain period of time", and this is a typical refrigeration cold storage. For example, meat and aquatic products have high requirements for the storage temperature to keep the meat from deteriorating. And during the sales process, they also need to be taken out and stored irregularly. Generally, the cold storages in large supermarkets are refrigeration cold storages. - Quick-freezing Cold Storage:

The temperature of a quick-freezing cold storage is generally between -35°C and -40°C, used for the rapid freezing of materials. The temperature of a low-temperature refrigeration cold storage is generally between -18°C and -20°C, used for the long-term storage of materials after quick freezing. It uses various refrigeration equipment, that is, the way of artificial refrigeration, to keep the indoor temperature at a certain low level.

Compared with the fresh-keeping cold storage, the action mechanism of the freezing cold storage is very different. Too low a temperature will cause the death of the cell tissues of foods such as meat and seafood, and the freshness will be greatly affected.

Therefore, for the storage of fruits, vegetables, and meat, it is not that the lower the temperature, the better.

III. What Should Be Paid Special Attention to When Designing a Quick-freezing Cold Storage - Understand the purpose of the cold storage and conduct on-site inspections at the cold storage site to collect the parameters of the cold storage. The specific parameters of the cold storage site are very important. The actual size of the cold storage site, the surrounding environment, etc., all directly affect the cold storage equipment selected during the design of the quick-freezing cold storage and the construction drawings of the cold storage.

- Select an appropriate freezing temperature and freezing time according to the characteristics of the items to be stored in the cold storage. Different types of products have different temperature requirements. For example, the temperature requirements of products such as tuna for the quick-freezing cold storage are different from those of general fresh products. The central temperature of the frozen items needs to reach -50 degrees to ensure the quality of the fish meat. Therefore, the understanding of the characteristics of products, etc., in the quick-freezing cold storage should be accurate!

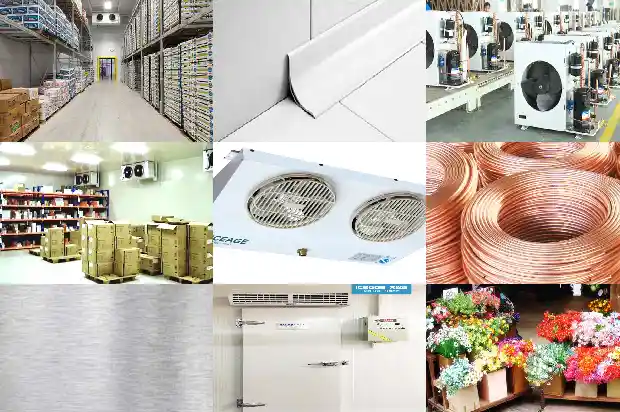

After determining the above two points, then select the cold storage equipment, cold storage parts, etc.

, to be used in the quick-freezing cold storage.

IV. Precautions for the Installation of a Quick-freezing Cold Storage - Affected by the low temperature, the foundation of the quick-freezing cold storage is such that the water in the soil is likely to be frozen. Since the volume of the soil expands after freezing, it will cause the ground to crack and the entire building structure to deform. In severe cases, the cold storage cannot be used. Therefore, in addition to having an effective thermal insulation layer, the floor of the quick-freezing cold storage must also be treated under the thermal insulation layer to prevent the soil from freezing.

- In the installation of the quick-freezing cold storage, stainless steel plates, embossed aluminum plates, colored steel plates, and plastic-coated steel plates are used as the panels, and rigid polyurethane foam plastic is used as the thermal insulation material, and composite wall panels are made using advanced processes. The inner and outer panels of the cold storage panels are both made of colored steel plates (the base material is galvanized steel plates), and the core material of the cold storage panels is foamed rigid polyurethane or polystyrene foam board pasted. Since all components except the floor are prefabricated in a complete set in a professional factory according to unified standards and assembled on the construction site, the construction progress is fast and the construction period is short.

- The quick-freezing cold storage is divided into three levels, L, D, and J, with the storage temperatures being 5°C to -5°C, -10°C to -18°C, and -20°C to -23°C respectively. Special cold storages can reach below -30°C, which can meet different needs. It is an ideal cold storage required for storing meat, aquatic products, poultry eggs, dairy products, fruits, vegetables, industrial raw materials, and for creating a low-temperature test environment, and is widely applicable to various industries.

- The installation and disassembly of the quick-freezing cold storage are convenient: The cold storage body uses a buckle connection of embedded parts inside the panel walls, which is convenient for installation, disassembly, and transportation.

The assembly and startup time is short, and the installation period is only 1/30 to 1/20 of that of a civil construction cold storage. Small and medium-sized cold storages can generally be delivered for use within 3 to 5 days, which is particularly suitable for mobile units such as the military, factories and mines, and remote areas.

- Due to the excellent thermal insulation performance of the quick-freezing cold storage, the cooling speed is fast and the thermal insulation time is long. Compared with other cold storages, it can generally save 30% to 40% of energy.

V. Precautions for the Use and Maintenance of a Quick-freezing Cold Storage: - Prevent the freezing-thawing cycle, freezing embrittlement, and freezing swelling of the building structure.

- Protect the floor to prevent freezing swelling and damage.

- When using the quick-freezing cold storage, it should be used in accordance with the design requirements, give full play to the freezing and refrigeration capabilities, ensure safe production and product quality, and maintain the building structure of the cold storage well. A special team should be set up to manage the storage room, and the responsibility should be assigned to each person. Each storage door and each piece of equipment and tool should have someone in charge.

- The quick-freezing cold storage is made of thermal insulation materials and has the characteristics of being afraid of water, moisture, hot air, and cold air leakage. It is necessary to control the five aspects of ice, frost, water, doors, and lights well.

- The storage capacity of the quick-freezing cold storage must be reasonably utilized. Continuously summarize and improve the method of stacking goods, arrange the storage locations and stacking heights safely and reasonably, improve the utilization rate of the cold storage. The stacking should be firm and neat, facilitating inventory checking, inspection, and the entry and exit of goods.

Related Articles

- Analysis of the Causes of Frost Formation at the Suction Port of the Refrigeration Compressor

- Analysis of Common Faults of Chillers

- Analysis by Experts: Why Does the Four-way Reversing Valve Fail?

- Analysis of the Main Functions and Components of Refrigeration Air Conditioners

- Brief Analysis of Commonly Used Automatic Control Devices in the Refrigeration System

- Analysis of Common Auxiliary Components in the Refrigeration System One by One

- A Detailed Analysis of the Nine Reasons for the Low Pressure in the Refrigeration System!

- Analysis of the Working Process and Principle of Hot Fluoride Defrosting for Air Coolers

- Advantages and Disadvantages of Air-cooled Multi-connected Units and Analysis of Their Components

- Cause Analysis of High Discharge Temperature and Overload Protection of Modular Units

- Analysis of the Causes and Hazards of Corrosion in the Circulating Water System

- Analysis of Common Auxiliary Components in the Refrigeration System

- Analysis of the Composition, Control and Operation Process of Cold Storage System

- Analysis of Causes for Compressor Liquid Hammer, Overheating and Pre - heating

- Analysis of Seven Reasons for Ice Formation in Computer Room Air Conditioners

- Analysis and Troubleshooting of Common Faults in Air - source Heat Pumps

- Analysis of 6 Components in Air - cooled Multi - split Systems

- Analysis of Advantages, Disadvantages and 34 Common Components of Multi - split Air Conditioners