Advantages of Evaporative Condensers

2024-07-26

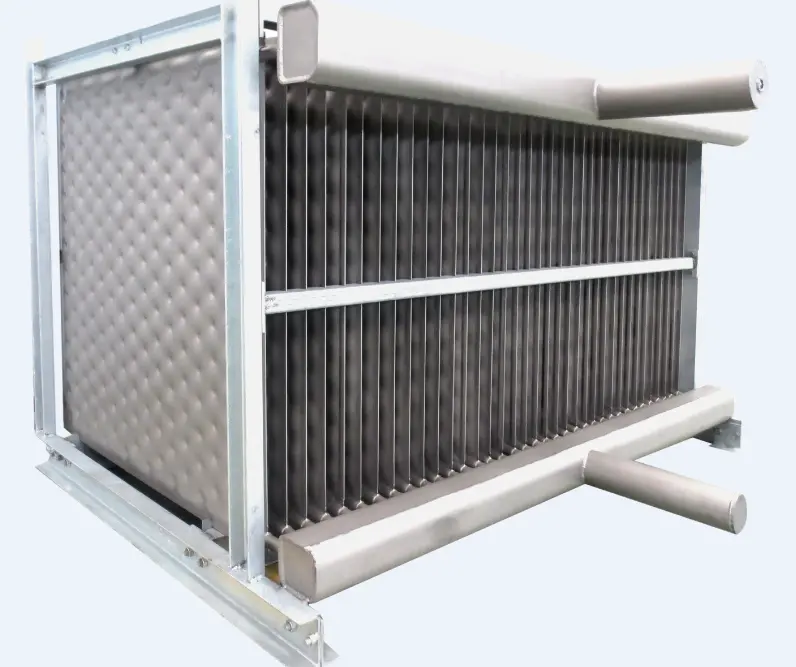

The condenser is one of the main heat exchange equipment in the refrigeration system. Its function is to cool the high-temperature and superheated refrigerant vapor discharged from the compressor into a liquid state. Since the 1970s, developed countries have begun to replace water-cooled condensers with evaporative condensers. Evaporative condensers are applied in various refrigeration systems, including cold storages, central air conditioning, industrial refrigeration units, ammonia refrigeration systems, etc.

Performance advantages of evaporative condensers:

- Water conservation

The evaporative condenser makes full use of the latent heat of vaporization of water. Generally, each 1 Kg of cooling water in a water-cooled condenser can take away 16.75 - 25.12 KJ of heat, while 1 Kg of water can take away about 2428 KJ of heat when evaporating at room temperature. Therefore, the theoretical water consumption of the evaporative condenser is only 1% of that of the water-cooled condenser. Considering factors such as splash loss, sewage discharge and water change, the actual water consumption is about 5% - 10% of that of the water-cooled condenser. The evaporative condenser greatly reduces the loss of water, which is of great significance for the northern regions of China where water resources are severely insufficient. - Energy conservation

The condensing capacity of air-cooled condensers is limited by the ambient dry bulb temperature, while that of evaporative condensers is limited by the ambient wet bulb temperature, and the wet bulb temperature is 8 - 14°C lower than the general dry bulb temperature. Coupled with the negative pressure environment caused by the upper fan to the equipment, the condensing temperature of the evaporative condenser is lower compared to the air-cooled condenser. For every 1°C increase in the condensing temperature, the power consumption per unit of refrigeration capacity will increase by 3% - 3.5%. Therefore, the total power consumption of the evaporative condenser is also significantly reduced, and the energy-saving effect is obvious. In HVAC systems, it can save energy by 20% - 40% compared to other condensers. - Compact structure

Since there is no need to set up a cooling tower, the entire device has a compact structure, small size, less floor space, and is convenient for installation and has a small amount of daily maintenance work. - No environmental pollution

Many chemical plants used to adopt shell-and-tube or spray condensers. In summer, due to the excessive condensing pressure, "venting and pressure reduction" was often adopted. But each time, it was not non-condensable gas that was released, but contained a large amount of ammonia. According to sampling and analysis by relevant departments, sometimes it was as high as 90%. Not only was the ammonia loss quite serious, but it also caused environmental pollution. However, this phenomenon does not exist when using evaporative condensers.

At present, evaporative condensers are widely used in Western developed countries. In domestic applications, due to the water shortage in the northwest region, evaporative condensers are more widely used in the northwest region. Cooling and air conditioning equipment in civil buildings such as hotels, office buildings, shopping malls, factory workshops, cold storages, and greenhouses basically adopt evaporative condensers.

For example, a 10,000-ton cold storage of a certain aquatic product company was originally equipped with a vertical shell-and-tube condenser. The cooling water was directly from natural lake water, and three sets of water pumps were equipped. The condenser used was severely corroded and the equipment maintenance cost was high. Later, an evaporative condenser was adopted to replace the original vertical shell-and-tube condenser, saving about 300,000 yuan per year, and the equipment failure rate decreased, and the improvement effects in all aspects were obvious.

Related Articles

- Three Common Methods for Removing Water Scale from Water - cooled Condensers

- Cleaning Methods for Different Types of Condensers in Refrigeration Devices

- All-round Introduction to Condensers and Evaporators!

- Introduction to Types of Condensers in Cold Storage

- Analysis of Advantages, Disadvantages and 34 Common Components of Multi - split Air Conditioners

- Why Can't Compressors Start Directly? What Are the Advantages of Soft Starters?

- Introduction to the Advantages of Dual - temperature Cold Storage

- Advantages and Disadvantages of Indirect Refrigeration System

- What is Indirect Evaporative Cooling Technology?

- What should we pay attention to when installing evaporative condenser?