All-round Introduction to Condensers and Evaporators!

2024-11-19

Condenser

Classification (by cooling method)

Air-cooled condensers, water-cooled condensers (shell-and-tube condensers, double-pipe condensers, shell-coil condensers, spiral plate condensers, immersion condensers), evaporative condensers and spray condensers.

Classification (by cooling method)

Air-cooled condensers, water-cooled condensers (shell-and-tube condensers, double-pipe condensers, shell-coil condensers, spiral plate condensers, immersion condensers), evaporative condensers and spray condensers.

Air-cooled Condensers

- Application Objects:

Often used in some small refrigeration devices such as refrigerators, freezers, small air conditioners, refrigerated trucks, and automotive air conditioners.

Advantages: No need for water, simple installation, and can be placed on the roof; low heat transfer coefficient, greatly affected by ambient temperature, harmful to the environment, and difficult to remove dust.

Limitations: Only used in Freon refrigeration machines.

Classification: According to the air flow situation, it can be divided into natural convection cooling condensers and forced convection cooling condensers. - Natural Convection Cooling Condensers

(1) Composition: Red copper pipes (seamless steel pipes) and copper-plated steel wires.

(2) Characteristics: No fan, saving electricity consumption, low noise, and low heat transfer coefficient. - Forced Convection Cooling Condensers

(1) Composition:

Red copper pipes (seamless steel pipes), fins and axial flow fans.

(2) Principle

(3) Characteristics

High electricity consumption, loud noise, and high heat transfer coefficient.

Water-cooled Condensers

- Shell-and-tube Water-cooled Condensers

Characteristics: High heat transfer coefficient, small floor area, and convenient for cleaning; large water consumption and bulky.

Applicable to: Large and medium-sized ammonia refrigeration systems.

Horizontal shell-and-tube condensers:

Applicable to: Ammonia or Freon refrigeration systems. - Double-pipe Condensers

Characteristics: High heat transfer coefficient, small unit floor area, simple structure; large metal consumption, difficult to clean, and high water resistance. - Shell-coil Condensers

Characteristics: Simple structure, unable to be mechanically cleaned, strict requirements on water quality, and in need of regular chemical cleaning. - Spiral Plate Condensers

Characteristics: Small volume, light weight, high heat transfer coefficient, but not suitable for high pressure, difficult to clean and maintain internally, and strict requirements on water quality.

Evaporative Condensers

Characteristics: Water-saving, low cost, simple structure, easy to remove scale, and small volume.

Characteristics: Water-saving, low cost, simple structure, easy to remove scale, and small volume.

Spray Condensers

Characteristics: Simple structure, convenient to use, easy to remove scale, low requirements on water quality, but large metal consumption, large floor area, and low heat transfer coefficient.

Characteristics: Simple structure, convenient to use, easy to remove scale, low requirements on water quality, but large metal consumption, large floor area, and low heat transfer coefficient.

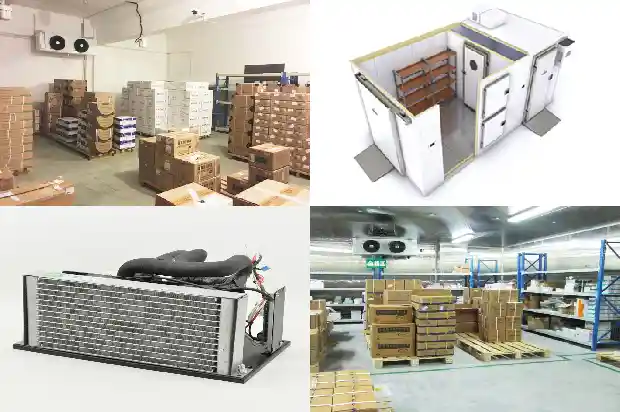

Evaporator

- Function:

The refrigerant liquid vaporizes in the evaporator and absorbs the heat of the cooled medium to achieve the purpose of refrigeration. - Classification

According to the filling degree and evaporation situation of the evaporator, it is divided into four types:

Dry (non-flooded) evaporators, recirculating evaporators, flooded evaporators, and spray evaporators.

Dry Evaporators

- Definition:

An evaporator in which the refrigerant liquid is completely vaporized once inside the tube. - Working Process:

- Applicable Objects: Commonly used in cold storages or cool storage air conditioners.

- Characteristics of Dry Evaporators

(1) Advantages: Small amount of liquid charge, no need for a liquid receiver or only a small liquid receiver is needed, easy to return the lubricating oil in the evaporator to the compressor, small cooling capacity loss, and can reduce the risk of freezing.

(2) Disadvantages: Low heat transfer coefficient. - Classification:

According to the difference of the cooled objects, it can be divided into: liquid cooling type (U-tube type, straight tube type, plate type evaporators), air cooling type (smooth tube type, finned tube type).

(1) U-tube Dry Evaporators

Advantages: Tube bundles can be assembled in advance, the dirt outside the tubes can be removed by extraction, thermal stress can be eliminated, the refrigerant is evenly distributed, and the heat transfer effect is good.

Disadvantages: Different molds need to be used when manufacturing tube bundles, longitudinal internal finned tubes cannot be used, and it is not easy to replace the tubes when they are damaged.

(2) Straight Tube Dry Evaporators

Composition: Shell, tube pass, baffle plate, end cover, tube sheet, etc.;

In order to improve the heat transfer coefficient, the inner tube can adopt a smooth tube or a tube with longitudinal internal fins,

Generally, external finned tubes are not used.

(3) Plate Evaporators

Advantages: Low resistance, compact structure, low metal consumption, and adjustable heat transfer area, etc.

Recirculating Evaporators

- Definition:

An evaporator in which the refrigerant liquid needs to go through several cycles to be completely vaporized. Working Principle: - Characteristics:

It has a relatively high heat transfer coefficient, but it has a large volume, requires a large amount of refrigerant, and has high operating costs.

Flooded Evaporators

- Working Principle

- Characteristics:

Compact structure, good heat transfer effect, easy to install and use; but a large amount of refrigerant is charged, the evaporation temperature at the bottom is slightly higher, which reduces the heat transfer temperature difference. For Freon evaporators, it is more difficult to discharge the lubricating oil, and the refrigerant is prone to freezing. - Other Types of Evaporators

Related Articles

- Both are dual - connected systems. How to choose between air - fluorine - ground - water and air - water - ground - water systems after all?

- Introduction to Inspection and Handling Methods for Refrigerant Leak in Cold Storage

- Introduction to Control Valves in Refrigeration Systems

- Introduction to Basic Types of Cold Storage

- Introduction to Lithium Bromide Absorption Chillers

- Introduction to the Advantages of Dual - temperature Cold Storage

- Introduction to Various Water Tanks in Air - conditioning Systems

- Introduction to the Cleaning Processes and Methods of Heat Exchangers and Cooling Towers

- Introduction to Six Kinds of Two-stage Compression Refrigeration Systems

- Introduction to Key Points of Compressor Grouping in Quick-freezing Cold Storage

- Introduction to the Construction and Features of Cold Storage in Cold Chain Logistics

- Introduction to Vapor Barrier of Cold Storage and Moisture Protection of Equipment

- Introduction to Oil Collector in Refrigeration System

- Technical Introduction of Process Cooling Water System

- Introduction to Air-cooled Chiller

- Introduction to Five Classification Functions of Cold Storage Installation for Refrigeration

- Introduction to Precooling Methods for Fruits and Vegetables

- Introduction to the Relationship between Refrigerants and Cold Storage Temperatures