Analysis of Advantages, Disadvantages and 34 Common Components of Multi - split Air Conditioners

2025-01-02

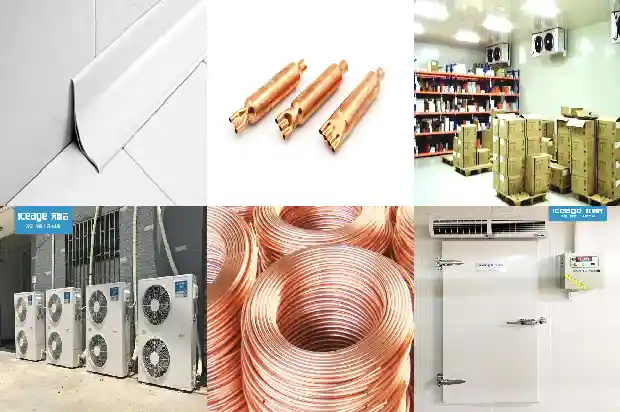

Multi - connected air conditioners, commonly known as "one - to - multiple", refer to a type of air - conditioning system where one outdoor unit is connected to two or more indoor units through pipes. The outdoor side adopts air - cooled heat - exchange form, and the indoor side uses direct - evaporation heat - exchange form.

The central air - conditioning system of multi - connected air conditioners solves the problem of all - or - nothing operation in traditional central air - conditioners. It can control the startup of indoor units more intelligently, which not only facilitates people's lives but also significantly saves energy consumption.

Analysis of the Advantages and Disadvantages of Multi - connected Air Conditioners

Advantages:

◆ There are fewer outdoor units, which does not affect the appearance of the building.

◆ The construction cost is lower than that of water - cooled units, and the operating cost is relatively low.

◆ The control is flexible, and some brands can even achieve remote control via telephone and modem.

◆ The noise level is low, and the operation is quiet.

◆ The installation is simple. It does not require three - phase power supply, and the construction period is short.

Disadvantages:

◆ There are limitations on the length of the refrigerant pipe and the height difference between the indoor and outdoor units, so it is not suitable for rooms with a large depth.

◆ The static pressure outside the unit is small, and the air - supply distance is short.

◆ The cooling (heating) capacity of a single unit is limited and cannot meet the air - conditioning requirements of larger rooms.

◆ Generally, one indoor unit requires a set of control circuits. The wiring is complicated and prone to malfunctions.

Advantages:

◆ There are fewer outdoor units, which does not affect the appearance of the building.

◆ The construction cost is lower than that of water - cooled units, and the operating cost is relatively low.

◆ The control is flexible, and some brands can even achieve remote control via telephone and modem.

◆ The noise level is low, and the operation is quiet.

◆ The installation is simple. It does not require three - phase power supply, and the construction period is short.

Disadvantages:

◆ There are limitations on the length of the refrigerant pipe and the height difference between the indoor and outdoor units, so it is not suitable for rooms with a large depth.

◆ The static pressure outside the unit is small, and the air - supply distance is short.

◆ The cooling (heating) capacity of a single unit is limited and cannot meet the air - conditioning requirements of larger rooms.

◆ Generally, one indoor unit requires a set of control circuits. The wiring is complicated and prone to malfunctions.

Analysis of Each Component of Multi - connected Air Conditioners

◆ Compressor (1): The heart of the refrigeration system. It sucks in low - temperature and low - pressure gaseous refrigerant and discharges high - temperature and high - pressure gaseous refrigerant. The compressor is the power source of the refrigeration system.

◆ Compressor heating tape (2): It increases the temperature of the compressor, volatilizes the liquid refrigerant inside into gas, and avoids liquid hammering to the compressor. Generally, this heating tape comes into play when the unit is powered on for the first time after installation or when it has not been used for a long time in winter.

◆ Compressor exhaust temperature sensing bulb (3): It detects the exhaust temperature of the compressor to prevent the exhaust temperature from exceeding the set temperature, so as to control and protect the compressor.

◆ High - pressure switch (4): When the exhaust pressure of the compressor exceeds the action value of the high - pressure switch, it immediately sends a feedback signal to stop the operation of the entire unit, achieving the purpose of protecting the compressor.

◆ Oil separator (5): It separates the lubricating oil from the high - pressure steam discharged by the refrigeration compressor. At this time, relying on the oil separator, the refrigerant and oil in the system are separated to prevent a large amount of refrigeration oil from entering the refrigeration system and the compressor from lacking oil. At the same time, through separation, the heat - transfer effect in the condenser and evaporator is improved.

◆ Oil equalizer (6): The function of the oil equalizer is to "balance the oil level between different parts of the air - conditioning system" to prevent oil shortage in some parts.

◆ Check valve (7): In the refrigeration system, it prevents the reverse flow of refrigerant, prevents high - pressure gas from entering the compressor in the wrong direction, and quickly balances the suction and exhaust pressures of the compressor.

◆ High - pressure sensor (8): It detects the real - time high - pressure value of the refrigeration system. If the high - pressure value exceeds the set value, it sends a feedback signal to protect the compressor and perform other controls.

◆ Four - way valve (9): The four - way valve consists of three parts: a pilot valve, a main valve, and an electromagnetic coil. By turning on or off the current of the electromagnetic coil, the left or right valve plug is opened or closed. Thus, the pressures on both sides of the valve body can be controlled by the left and right capillaries, causing the slider in the valve body to slide left or right under the pressure difference, thereby changing the flow direction of the refrigerant to achieve the purpose of cooling or heating.

◆ Condenser (10): The condenser cools the high - temperature and high - pressure refrigerant vapor discharged by the compressor. The high - temperature and high - pressure refrigerant gas condenses here and exchanges heat with air through forced convection.

◆ Fan (11): Its main function is to strengthen convective heat transfer, increase the heat - exchange effect. It absorbs heat and dissipates cold during cooling, and absorbs cold and dissipates heat during heating.

◆ Defrosting temperature sensing bulb (12): It controls the reset temperature of defrosting. When the set temperature of the temperature sensing bulb is reached, defrosting stops. It is used for defrosting detection and control.

◆ Electronic expansion valve (13): The function of the electronic expansion valve is throttling. The main difference between it and the capillary thermostatic expansion valve is that its opening is controlled by a controller. It can adjust the opening of the valve port according to needs, thereby controlling the flow rate. Using an electronic expansion valve can make the flow - rate adjustment more accurate, but the price is relatively much higher.

◆ Check valve (14): It prevents the reverse flow of refrigerant in the refrigeration system.

◆ Sub - cooler electronic expansion valve (15): When the system is operating in the refrigeration mode, it controls the sub - cooling degree of the liquid - pipe refrigerant, reduces the pipeline energy loss, and increases the cooling capacity of the refrigeration system.

◆ Sub - cooler liquid - outlet temperature sensing bulb (16): It detects the temperature of the liquid pipe, sends it to the control board, and adjusts the opening of the electronic expansion valve.

◆ Gas - liquid separator inlet pipe temperature sensing bulb (17): It detects the temperature of the inlet pipe of the gas - liquid separator to avoid the compressor running with liquid return.

◆ Sub - cooler outlet temperature sensing bulb (18): It detects the gas - side temperature of the sub - cooler, inputs it to the control board, and adjusts the opening of the expansion valve.

◆ Gas - liquid separator outlet pipe temperature sensing bulb (19): It detects the internal state of the gas - liquid separator to further control the suction state of the compressor.

◆ Ambient temperature sensing bulb (20): It detects the ambient temperature in which the outdoor unit operates.

◆ Low - pressure sensor (21): It detects the low - pressure of the refrigeration system. If the low - pressure is too low, it sends a feedback signal to avoid the operation with too low a pressure, which may cause compressor failure.

◆ Gas - liquid separator (22): The main function of the gas - liquid separator is to store part of the refrigerant in the system, prevent the compressor from liquid hammering, and prevent the refrigerant from being too much and diluting the compressor oil.

◆ Unloading valve (23): The main function of the unloading valve is to automatically control unloading or loading to avoid dead zones in the pipeline, which may lead to excessive pressure.

◆ Oil return solenoid valve (24): Simply put, when the compressor oil is low, the solenoid valve opens to let the oil return. When the oil is detected to be in place, the solenoid valve closes to ensure the supply of lubricating oil.

◆ Pressure - balance valve (25): It balances the suction and exhaust pressures of the refrigeration system to ensure the successful startup of the compressor.

◆ Oil return temperature sensing bulb (26): It detects the oil return temperature to prevent the oil return pipeline from being blocked or leaking.

◆ Capillary tube (27): It throttles and reduces the pressure. The high - pressure Freon refrigerant from the condenser is throttled and reduced to a low - pressure Freon refrigerant, and then it vaporizes and absorbs heat in the evaporator.

◆ Sub - cooler (28): It is used to control the sub - cooling degree of the liquid pipe.

◆ Drier - filter (29): It has the function of absorbing moisture in the system.

◆ Filter (30): The drier - filter mainly plays the role of filtering impurities and absorbing moisture in the system.

◆ Liquid - pipe shut - off valve (31): It cuts off the refrigerant and connects to the indoor unit.

◆ Low - pressure measuring valve (32): It is used to detect the low - pressure value when the refrigeration system is running or for refrigerant charging during operation.

◆ Gas - pipe shut - off valve (33): It cuts off the refrigerant and connects to the indoor unit.

◆ Oil detection valve (34): During maintenance, it checks the quality of the refrigeration oil of the compressor.

◆ Compressor (1): The heart of the refrigeration system. It sucks in low - temperature and low - pressure gaseous refrigerant and discharges high - temperature and high - pressure gaseous refrigerant. The compressor is the power source of the refrigeration system.

◆ Compressor heating tape (2): It increases the temperature of the compressor, volatilizes the liquid refrigerant inside into gas, and avoids liquid hammering to the compressor. Generally, this heating tape comes into play when the unit is powered on for the first time after installation or when it has not been used for a long time in winter.

◆ Compressor exhaust temperature sensing bulb (3): It detects the exhaust temperature of the compressor to prevent the exhaust temperature from exceeding the set temperature, so as to control and protect the compressor.

◆ High - pressure switch (4): When the exhaust pressure of the compressor exceeds the action value of the high - pressure switch, it immediately sends a feedback signal to stop the operation of the entire unit, achieving the purpose of protecting the compressor.

◆ Oil separator (5): It separates the lubricating oil from the high - pressure steam discharged by the refrigeration compressor. At this time, relying on the oil separator, the refrigerant and oil in the system are separated to prevent a large amount of refrigeration oil from entering the refrigeration system and the compressor from lacking oil. At the same time, through separation, the heat - transfer effect in the condenser and evaporator is improved.

◆ Oil equalizer (6): The function of the oil equalizer is to "balance the oil level between different parts of the air - conditioning system" to prevent oil shortage in some parts.

◆ Check valve (7): In the refrigeration system, it prevents the reverse flow of refrigerant, prevents high - pressure gas from entering the compressor in the wrong direction, and quickly balances the suction and exhaust pressures of the compressor.

◆ High - pressure sensor (8): It detects the real - time high - pressure value of the refrigeration system. If the high - pressure value exceeds the set value, it sends a feedback signal to protect the compressor and perform other controls.

◆ Four - way valve (9): The four - way valve consists of three parts: a pilot valve, a main valve, and an electromagnetic coil. By turning on or off the current of the electromagnetic coil, the left or right valve plug is opened or closed. Thus, the pressures on both sides of the valve body can be controlled by the left and right capillaries, causing the slider in the valve body to slide left or right under the pressure difference, thereby changing the flow direction of the refrigerant to achieve the purpose of cooling or heating.

◆ Condenser (10): The condenser cools the high - temperature and high - pressure refrigerant vapor discharged by the compressor. The high - temperature and high - pressure refrigerant gas condenses here and exchanges heat with air through forced convection.

◆ Fan (11): Its main function is to strengthen convective heat transfer, increase the heat - exchange effect. It absorbs heat and dissipates cold during cooling, and absorbs cold and dissipates heat during heating.

◆ Defrosting temperature sensing bulb (12): It controls the reset temperature of defrosting. When the set temperature of the temperature sensing bulb is reached, defrosting stops. It is used for defrosting detection and control.

◆ Electronic expansion valve (13): The function of the electronic expansion valve is throttling. The main difference between it and the capillary thermostatic expansion valve is that its opening is controlled by a controller. It can adjust the opening of the valve port according to needs, thereby controlling the flow rate. Using an electronic expansion valve can make the flow - rate adjustment more accurate, but the price is relatively much higher.

◆ Check valve (14): It prevents the reverse flow of refrigerant in the refrigeration system.

◆ Sub - cooler electronic expansion valve (15): When the system is operating in the refrigeration mode, it controls the sub - cooling degree of the liquid - pipe refrigerant, reduces the pipeline energy loss, and increases the cooling capacity of the refrigeration system.

◆ Sub - cooler liquid - outlet temperature sensing bulb (16): It detects the temperature of the liquid pipe, sends it to the control board, and adjusts the opening of the electronic expansion valve.

◆ Gas - liquid separator inlet pipe temperature sensing bulb (17): It detects the temperature of the inlet pipe of the gas - liquid separator to avoid the compressor running with liquid return.

◆ Sub - cooler outlet temperature sensing bulb (18): It detects the gas - side temperature of the sub - cooler, inputs it to the control board, and adjusts the opening of the expansion valve.

◆ Gas - liquid separator outlet pipe temperature sensing bulb (19): It detects the internal state of the gas - liquid separator to further control the suction state of the compressor.

◆ Ambient temperature sensing bulb (20): It detects the ambient temperature in which the outdoor unit operates.

◆ Low - pressure sensor (21): It detects the low - pressure of the refrigeration system. If the low - pressure is too low, it sends a feedback signal to avoid the operation with too low a pressure, which may cause compressor failure.

◆ Gas - liquid separator (22): The main function of the gas - liquid separator is to store part of the refrigerant in the system, prevent the compressor from liquid hammering, and prevent the refrigerant from being too much and diluting the compressor oil.

◆ Unloading valve (23): The main function of the unloading valve is to automatically control unloading or loading to avoid dead zones in the pipeline, which may lead to excessive pressure.

◆ Oil return solenoid valve (24): Simply put, when the compressor oil is low, the solenoid valve opens to let the oil return. When the oil is detected to be in place, the solenoid valve closes to ensure the supply of lubricating oil.

◆ Pressure - balance valve (25): It balances the suction and exhaust pressures of the refrigeration system to ensure the successful startup of the compressor.

◆ Oil return temperature sensing bulb (26): It detects the oil return temperature to prevent the oil return pipeline from being blocked or leaking.

◆ Capillary tube (27): It throttles and reduces the pressure. The high - pressure Freon refrigerant from the condenser is throttled and reduced to a low - pressure Freon refrigerant, and then it vaporizes and absorbs heat in the evaporator.

◆ Sub - cooler (28): It is used to control the sub - cooling degree of the liquid pipe.

◆ Drier - filter (29): It has the function of absorbing moisture in the system.

◆ Filter (30): The drier - filter mainly plays the role of filtering impurities and absorbing moisture in the system.

◆ Liquid - pipe shut - off valve (31): It cuts off the refrigerant and connects to the indoor unit.

◆ Low - pressure measuring valve (32): It is used to detect the low - pressure value when the refrigeration system is running or for refrigerant charging during operation.

◆ Gas - pipe shut - off valve (33): It cuts off the refrigerant and connects to the indoor unit.

◆ Oil detection valve (34): During maintenance, it checks the quality of the refrigeration oil of the compressor.

Related Articles

- Analysis of Seven Reasons for Ice Formation in Computer Room Air Conditioners

- Analysis and Troubleshooting of Common Faults in Air - source Heat Pumps

- Analysis of 6 Components in Air - cooled Multi - split Systems

- Common Causes and Analysis of High and Low Pressure Alarms

- Common Causes and Analysis of Compressor Thermal Protection

- Analysis of Common Faults in Compressor Overcurrent and Burnout

- Analysis of Causes for Safety Valve Leakage

- Analysis of Refrigeration Compressor Motor Faults

- Fault Analysis of Working Principle of Screw Chiller Unit

- Analysis and Treatment of Common Low-Pressure Faults in Chillers

- Analysis and Treatment of Common Low Pressure Faults in Chillers

- Water Cooled Unit Principle of Operation and Parameter Failure Analysis

- Why Can't Compressors Start Directly? What Are the Advantages of Soft Starters?

- Introduction to the Advantages of Dual - temperature Cold Storage

- Advantages and Disadvantages of Indirect Refrigeration System

- Advantages of Evaporative Condensers

- Principles, Components and Heat Recovery of Modular Units

- Basic Knowledge of Valve - type Components in Refrigeration Systems (Technical Sharing)