Analysis of Selection Techniques for Thermal Insulation Materials in Seafood Freezer Construction

2025-04-05

What are the characteristics of a seafood freezer? Let's get to know the features of this product. In our daily life, we often come across seafood and other products that need to be frozen. Especially in summer, the weather is extremely hot. Due to the intense heat, seafood products tend to spoil quickly.

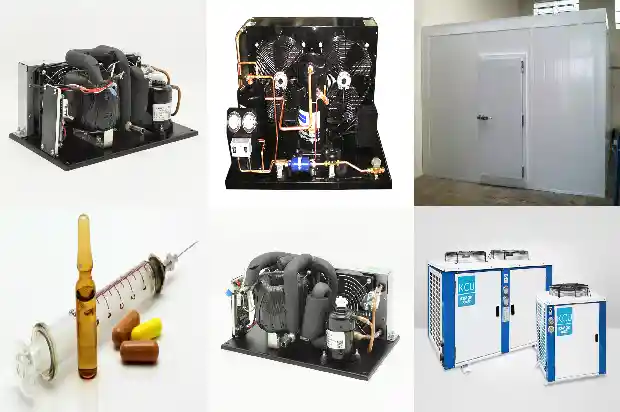

So, how do you determine what temperature your planned seafood freezer should have? Let's first talk about the seafood freezer with a temperature range of -30°C to -60°C. In fact, the difference in storage time between the -30°C to -60°C and -18°C to -23°C seafood freezers is that the -30°C to -60°C seafood freezer belongs to a "processing" low - temperature cold storage. It is mainly used for the quick - freezing processing of fresh seafood, aquatic products, fish, and shrimp. The -30°C to -60°C seafood freezer can also be called a seafood quick - freezing warehouse.

On the other hand, the -18°C to -23°C seafood freezer belongs to a "long - term storage" low - temperature cold storage. It is mainly used for the long - term storage of frozen seafood, aquatic products, fish, shrimp, and meat to prevent the previously quick - frozen products from thawing.

So, how should we choose the insulation materials for these two different types of seafood freezers? In fact, in our previous articles, we have mentioned the selection of insulation panels for cold storage design, stating that "the lower the temperature, the thicker the insulation material required." However, this is generally for ordinary cold storages.

There are exceptions, of course. For example, in the case of a controlled - atmosphere storage (CA storage), which is mostly used for storing fruits and vegetables. According to normal thinking, the temperature of a cold storage for fruit preservation is generally between 0°C and 5°C. So, would a 100 - mm - thick polyurethane insulation material be sufficient?

In fact, it still needs to be determined according to the actual situation. A CA storage has requirements for the gas composition inside the storage, and thus also has higher requirements for the insulation and sealing performance of the storage panels. However, for general low - temperature cold storages, the commonly selected insulation materials are 100 mm, 150 mm, or 200 mm thick. Specifically, it also depends on the region and the customers' requirements.

Related Articles

- The Most Comprehensive Analysis of Water Pump Failures in History, Summarized by an Expert!

- Operation: Analysis of 20 Major Faults of Screw Compressors!

- Analysis and Solutions for Common Faults in Refrigeration Systems

- Analysis of Common Malfunctions and Treatment Methods of Cold Storage Equipment

- Analysis of Causes for Exhaust Malfunctions of Screw - type Chiller Compressors

- Analysis of Classification, Differences, Advantages and Disadvantages of Cold Storage Refrigeration Compressors

- A Brief Analysis of Quick - Freezing Cold Storage Design

- Analysis of the Causes of Frost Formation at the Suction Port of the Refrigeration Compressor

- Analysis of Common Faults of Chillers

- Analysis by Experts: Why Does the Four-way Reversing Valve Fail?

- Analysis of the Main Functions and Components of Refrigeration Air Conditioners

- Brief Analysis of Commonly Used Automatic Control Devices in the Refrigeration System

- Analysis of Common Auxiliary Components in the Refrigeration System One by One

- A Detailed Analysis of the Nine Reasons for the Low Pressure in the Refrigeration System!

- Analysis of the Working Process and Principle of Hot Fluoride Defrosting for Air Coolers

- Advantages and Disadvantages of Air-cooled Multi-connected Units and Analysis of Their Components

- Cause Analysis of High Discharge Temperature and Overload Protection of Modular Units

- Analysis of the Causes and Hazards of Corrosion in the Circulating Water System