Analysis of the Composition, Control and Operation Process of Cold Storage System

2025-02-27

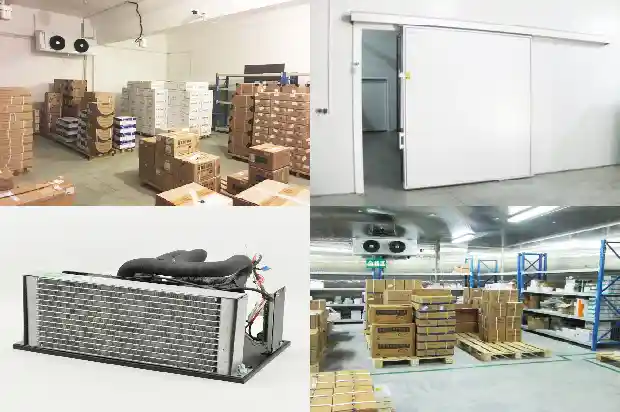

I. Composition of Small - scale Cold Storage System

The figure shows a refrigeration unit composed of a cold storage, mainly including: refrigeration compressor, air cooler, thermal expansion valve, solenoid valve, pressure relay, time relay, temperature relay, differential pressure relay, defrosting terminal, liquid - sight glass (dry - wet glass), oil separator, and gas - liquid separator.

II. Principle of the Cold Storage Refrigeration System

The refrigerant flows from the DX dryer - filter to the thermal expansion valve TE. The stop valve BM is installed in front of the dryer - filter DX, which facilitates the replacement of the dryer - filter. In front of each thermal expansion valve TE, a solenoid valve EVR is installed and controlled by a temperature controller (nowadays, electronic temperature controllers are more commonly used) KP61. The temperature controller switches the solenoid valve according to the temperature at the thermostatic bulb F. A check valve NRV is installed on the suction pipeline from the evaporator of the low - temperature cold storage.

An evaporation pressure regulator KVP is installed on the suction pipeline from the evaporator of the high - temperature cold storage, which can maintain the evaporation pressure 8 - 10℃ below the temperature required in the refrigerating chamber. The pressure controller KP15 is a combined high - and low - pressure controller, which can prevent the compressor from having too low a suction pressure or too high an exhaust pressure, thus protecting the refrigeration unit.

An evaporation pressure regulator KVP is installed on the suction pipeline from the evaporator of the high - temperature cold storage, which can maintain the evaporation pressure 8 - 10℃ below the temperature required in the refrigerating chamber. The pressure controller KP15 is a combined high - and low - pressure controller, which can prevent the compressor from having too low a suction pressure or too high an exhaust pressure, thus protecting the refrigeration unit.

III. Supporting Facilities

The cold - storage door is equipped with anti - condensation heating wires (powered centrally or individually, with a voltage of 24V). This facility can effectively ensure that the cold - storage door is not frozen or condensed. A pressure - balance window is generally installed inside the modular cold storage. This facility can effectively prevent the bursting of the cold - storage panels caused by the increase in internal pressure. According to the user's requirements, an air curtain machine for the cold - storage door is set up.

IV. Functional Description of the Refrigeration System

(1) The refrigeration system is an automatic control system. When the temperature drops to the set value, the temperature controller closes the solenoid valve, the system stops supplying liquid, the pressure on the low - pressure side of the system decreases. When the pressure drops to the set value, the pressure controller acts, cutting off the control power supply of the compressor and the air cooler, and the refrigeration system stops working.

(2) Automatic startup. After the cold - storage temperature rises back to the set value, the temperature controller acts, the solenoid valve is energized to open and supply liquid, the pressure on the low - pressure side of the refrigeration system increases. When the pressure rises to the set value, the pressure controller acts, the control power supplies of the compressor and the air cooler are connected, and the refrigeration system starts to operate.

(3) Other functions of the pressure controller.

(4) Function of the differential pressure controller. The oil pressure gauge of the differential pressure relay can reflect the supply state of the lubricating oil (refrigeration oil) of the compressor. Its differential pressure is the difference between the oil pressure discharged by the oil pump and the suction pressure. Under normal conditions, the difference should be greater than 1.5 kg/cm² (value on the pressure gauge). When the differential pressure is less than 1.5 kg/cm², the differential pressure controller automatically shuts down within 60 seconds of operation, avoiding the operation of the compressor under poor lubrication conditions.

(5) "Electronic protection" function. When the compressor is a semi - hermetic compressor, its motor coil is set on the low - pressure side. Under normal circumstances, the heat generated by the coil during operation is cooled by the low - pressure working fluid gas. When for some reason the heat of the coil increases and cannot be cooled well, the heat of the coil will accumulate and increase. In severe cases, the coil will be burned out. "Electronic protection" can effectively ensure that the motor operates under normal temperature rise.

(6) Function of the water flow relay. The water flow relay ensures that the water - cooled unit operates when there is water. If the cooling water does not flow in the pipe or the water flow rate is insufficient, the water flow relay is in the open state, and the compressor cannot operate.

(7) A crankshaft heating wire is installed inside the crankcase of the compressor. When the compressor is working, the heating tube stops working; when the compressor stops working, the heating tube works. The crankshaft heating wire increases the temperature inside the crankcase, evaporating the working fluid in the mixture into gas, thus ensuring the purity of the refrigeration oil and the liquid level of the refrigeration oil.

(2) Automatic startup. After the cold - storage temperature rises back to the set value, the temperature controller acts, the solenoid valve is energized to open and supply liquid, the pressure on the low - pressure side of the refrigeration system increases. When the pressure rises to the set value, the pressure controller acts, the control power supplies of the compressor and the air cooler are connected, and the refrigeration system starts to operate.

(3) Other functions of the pressure controller.

(4) Function of the differential pressure controller. The oil pressure gauge of the differential pressure relay can reflect the supply state of the lubricating oil (refrigeration oil) of the compressor. Its differential pressure is the difference between the oil pressure discharged by the oil pump and the suction pressure. Under normal conditions, the difference should be greater than 1.5 kg/cm² (value on the pressure gauge). When the differential pressure is less than 1.5 kg/cm², the differential pressure controller automatically shuts down within 60 seconds of operation, avoiding the operation of the compressor under poor lubrication conditions.

(5) "Electronic protection" function. When the compressor is a semi - hermetic compressor, its motor coil is set on the low - pressure side. Under normal circumstances, the heat generated by the coil during operation is cooled by the low - pressure working fluid gas. When for some reason the heat of the coil increases and cannot be cooled well, the heat of the coil will accumulate and increase. In severe cases, the coil will be burned out. "Electronic protection" can effectively ensure that the motor operates under normal temperature rise.

(6) Function of the water flow relay. The water flow relay ensures that the water - cooled unit operates when there is water. If the cooling water does not flow in the pipe or the water flow rate is insufficient, the water flow relay is in the open state, and the compressor cannot operate.

(7) A crankshaft heating wire is installed inside the crankcase of the compressor. When the compressor is working, the heating tube stops working; when the compressor stops working, the heating tube works. The crankshaft heating wire increases the temperature inside the crankcase, evaporating the working fluid in the mixture into gas, thus ensuring the purity of the refrigeration oil and the liquid level of the refrigeration oil.

Related Articles

- Analysis of Causes for Compressor Liquid Hammer, Overheating and Pre - heating

- Analysis of Seven Reasons for Ice Formation in Computer Room Air Conditioners

- Analysis and Troubleshooting of Common Faults in Air - source Heat Pumps

- Analysis of 6 Components in Air - cooled Multi - split Systems

- Analysis of Advantages, Disadvantages and 34 Common Components of Multi - split Air Conditioners

- Common Causes and Analysis of High and Low Pressure Alarms

- Common Causes and Analysis of Compressor Thermal Protection

- Analysis of Common Faults in Compressor Overcurrent and Burnout

- Analysis of Causes for Safety Valve Leakage

- Analysis of Refrigeration Compressor Motor Faults

- Fault Analysis of Working Principle of Screw Chiller Unit

- Analysis and Treatment of Common Low-Pressure Faults in Chillers

- Analysis and Treatment of Common Low Pressure Faults in Chillers

- Water Cooled Unit Principle of Operation and Parameter Failure Analysis

- Composition and Common Faults of Screw Refrigeration Compressors

- Controlled Atmosphere Fresh - keeping Warehouse

- Prefabricated Controlled Atmosphere Warehouse - Prolonging the Fresh - keeping Period of Fruits and Vegetables

- Introduction to Control Valves in Refrigeration Systems