Causes and Solutions for Elevated Pressure in Cold Storage

2024-09-15

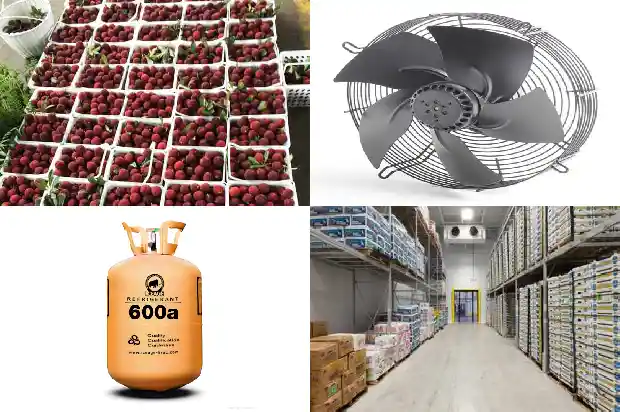

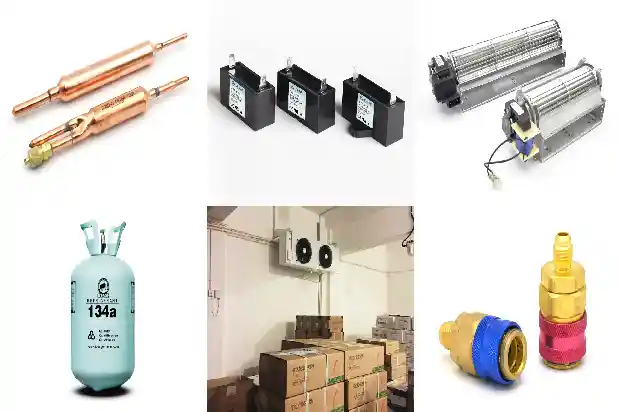

Causes and solutions for increased pressure in cold storage:

(1) The cold storage is too small. Replace or increase the cold storage.

(2) There are few workbenches put into use in the cold storage. Increase the number of workbenches.

(3) Lack of cooling water flow.

(4) The cooling water temperature is too high. Compensate with low-temperature water (tap water or well water); use defrosting water; ensure the cooling effect of the cooling tower. The cooling tower is an outdoor equipment. Due to the effect of the fan, a large amount of dust, leaves, insects, etc. will enter the tower. Over time, it will cause blockage of the cooling tower packing and pipelines.

(5) Reduction in heat exchange area of cold storage. Sufficient heat exchange area is an important guarantee for the heat exchange effect of cold storage. Especially for refrigeration systems using compression condensing units. Because the cold storage of such units also has the function of a liquid receiver.

(6) Uneven water distribution in the cold storage. When the water distribution is uneven, the water flow in some pipes is large and the water flow in some pipes is small, which will reduce the heat transfer power and increase the condensation temperature. Good water flow distribution should be that the water flows down rotating along the pipe wall. If the water flows down from the center of the pipe, most of the water flow will not have a condensation effect. Therefore, when the water distributor has uneven water distribution, the water distributor should be replaced.

(7) There is scale on the cold storage pipeline. The scale on the cold storage pipeline increases the thermal resistance, reduces the heat transfer coefficient, reduces the heat exchange effect, and increases the condensation temperature. Improve water quality and remove scale in time.

(8) There is air in the cold storage. The air in the cold storage increases the partial pressure of the system and the total pressure. The air will also form a gas layer on the surface of the cold storage, generating additional thermal resistance, reducing the heat transfer power, and causing the condensation pressure and condensation temperature to increase. Air should be released in time.

(1) The cold storage is too small. Replace or increase the cold storage.

(2) There are few workbenches put into use in the cold storage. Increase the number of workbenches.

(3) Lack of cooling water flow.

(4) The cooling water temperature is too high. Compensate with low-temperature water (tap water or well water); use defrosting water; ensure the cooling effect of the cooling tower. The cooling tower is an outdoor equipment. Due to the effect of the fan, a large amount of dust, leaves, insects, etc. will enter the tower. Over time, it will cause blockage of the cooling tower packing and pipelines.

(5) Reduction in heat exchange area of cold storage. Sufficient heat exchange area is an important guarantee for the heat exchange effect of cold storage. Especially for refrigeration systems using compression condensing units. Because the cold storage of such units also has the function of a liquid receiver.

(6) Uneven water distribution in the cold storage. When the water distribution is uneven, the water flow in some pipes is large and the water flow in some pipes is small, which will reduce the heat transfer power and increase the condensation temperature. Good water flow distribution should be that the water flows down rotating along the pipe wall. If the water flows down from the center of the pipe, most of the water flow will not have a condensation effect. Therefore, when the water distributor has uneven water distribution, the water distributor should be replaced.

(7) There is scale on the cold storage pipeline. The scale on the cold storage pipeline increases the thermal resistance, reduces the heat transfer coefficient, reduces the heat exchange effect, and increases the condensation temperature. Improve water quality and remove scale in time.

(8) There is air in the cold storage. The air in the cold storage increases the partial pressure of the system and the total pressure. The air will also form a gas layer on the surface of the cold storage, generating additional thermal resistance, reducing the heat transfer power, and causing the condensation pressure and condensation temperature to increase. Air should be released in time.

Related Articles

- What Are the Common Causes of Cold Air Blower Noise?

- Air - conditioner Low - pressure Alarm? These Nine Common Causes

- What Are the Causes of Scroll Compressor Damage?

- Causes and Prevention of "Primary Condensation" and "Secondary Condensation" in Fan - Coil Units

- 10 Symptoms and Causes of Abnormal Frosting in Heat Pumps

- Common Causes and Analysis of High and Low Pressure Alarms

- Common Causes and Analysis of Compressor Thermal Protection

- 4 Points on Causes of Water Leakage in Closed Cooling Towers

- Analysis of Causes for Safety Valve Leakage

- What Causes Noise in Pressure Reducing Valves?

- Common Causes of Frost Build-up in refrigerant evaporators

- What Causes Poor Refrigeration Effect of Refrigerated Trucks?

- Common Causes of Air Conditioner Compressor Failures

- Common Faults and Solutions of Central Air - conditioning Chiller Units

- Common Faults and Corresponding Solutions of Chillers During Use

- 9 Heating and Cooling Solutions: Pros and Cons You Must Know!

- Common Issues in Chiller Operation and Solutions

- Solutions to Common Compressor Failures