Chiller

2025-03-18

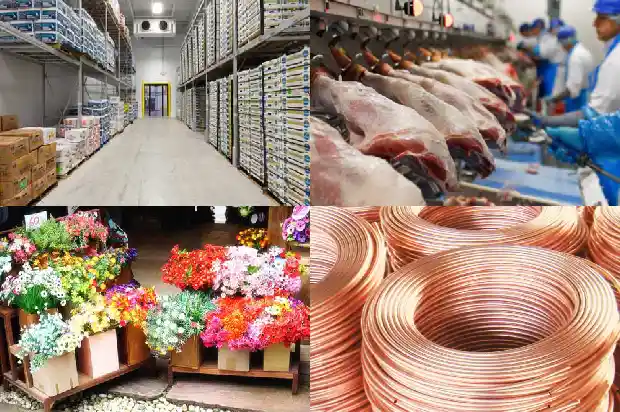

Chiller units, also known as refrigerators, chilled water units, refrigeration units, ice water units, cooling equipment, etc., are commonly seen in air - conditioning systems and industrial cooling systems, such as in the fields of laboratory equipment, chemical product manufacturing, pharmaceutical production, food processing, and beverage processing.

A chiller unit mainly realizes the state change of the flowing working fluid within the unit through four main components: compressor, evaporator, condenser, and expansion valve, thus achieving the effects of refrigeration and heating.

According to the different compressors used, chiller units include screw chiller units, scroll chiller units, centrifugal chiller units, and piston chiller units.

Based on different controlled temperatures, chiller units can be divided into low - temperature industrial chillers and normal - temperature chillers. The temperature of normal - temperature units is generally controlled within the range of 0℃ - 35℃. The temperature of low - temperature units is generally controlled around 0℃ - - 100℃. Industrial chillers can be classified into the following categories according to the water outlet temperature: water outlet temperature: - 25℃ - - 5℃; water outlet temperature: - 25℃ - - 45℃; water outlet temperature: below - 45℃.

According to different refrigeration forms, chiller units can generally be divided into water - cooled and air - cooled types. Water - cooled chiller units can be further divided into water - cooled chiller units, water - cooled brine chiller units, and water - cooled ethylene glycol chiller units according to different refrigerants. In daily use, many people simply call it a water - cooled unit.

A water - cooled chiller unit dissipates heat through water. That is, it uses a shell - and - tube evaporator to exchange heat between water and the refrigerant. After the refrigerant system absorbs the heat load in the water, cools the water to produce chilled water, and then through the action of the refrigeration compressor, the heat is carried to the shell - and - tube condenser. Heat exchange occurs between the refrigerant and water, and the water absorbs the heat and then takes the heat out through the water pipe to the external cooling tower for dissipation.

An air - cooled chiller unit uses a fin - type condenser, and the fan forces air to flow to take away the heat of the refrigerant. Compared with the components of a water - cooled chiller unit, it omits the cooling tower, cooling water pump, and cooling pipeline system, and has certain installation advantages. Air - cooled chiller units are suitable for use in water - scarce areas or mobile occasions, especially for small chiller units with low cooling capacity requirements.

In terms of energy efficiency, the cooling capacity of a water - cooled chiller unit is 300 - 500 kcal/h higher than that of an air - cooled chiller unit. In GB19577 "Minimum Allowable Values of Energy Efficiency and Energy Efficiency Grades for Chiller Units", the energy - efficiency grades of chiller units are specified. The manufacturer should indicate the rated energy - efficiency grade of the chiller unit in its product's factory - out documents.

Related Articles

- Analysis of Causes for Exhaust Malfunctions of Screw - type Chiller Compressors

- Analysis of Common Faults of Chillers

- Screw Chiller Units and Centrifugal Chillers

- What Are the Common Causes of High - pressure Faults in Chillers?

- What Are the Differences Between Chillers and General Water - cooled Equipment?

- Operation of Screw - type Water - cooled Chiller Units

- Common Faults and Solutions of Central Air - conditioning Chiller Units

- Maintenance Strategies for the Working Cycle and Electrical Automatic Control of Chillers

- What are Refrigeration Equipment? What's the Principle of Chillers?

- Common Faults of Industrial Chillers

- Can You Solve These 4 Common Issues of Industrial Chillers?

- Common Faults and Corresponding Solutions of Chillers During Use

- How to Install and Maintain Industrial Chillers?

- How to Clean a Chiller?

- Introduction to Lithium Bromide Absorption Chillers

- 8 Maintenance Procedures for Industrial Chillers

- Common Issues in Chiller Operation and Solutions

- Effective Measures to Prevent Compressor Failures in Industrial Chillers