Common Causes of Air Conditioner Compressor Failures

2024-08-30

- Wrong wiring of compressor

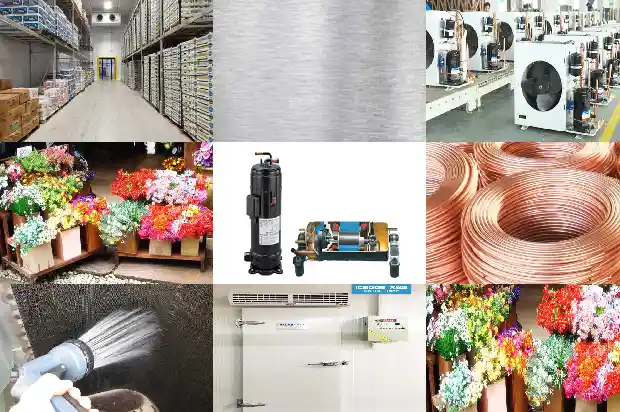

There is only one correct wiring method for the compressor, and all others are wrong. Due to wrong wiring, the thermal protector may lose its protection function, leading to the burnout of the compressor. Generally, the secondary coil will be burned out. - Foreign matter entering the air conditioning system

The sources of system residues may include: - Fine copper chips generated when cutting copper pipes.

- Foreign matters such as processing oil and impurities during the system manufacturing process.

- When the compressor is exposed to air for a long time, dust and water vapor enter.

- During welding, an oxide film will be generated on the inner surface of the pipeline, so nitrogen should be filled for protection during welding.

Impacts of residues on the system: - It will aggravate the wear of the friction surface of moving parts and block the pump oil passage.

- When the compressor contains tiny inclusions such as moisture, fibers, and dust, it may be adsorbed on the motor windings and terminals, reducing the insulation performance of the whole machine.

- Processing oil and the like will also react with refrigerant or refrigeration oil to produce sludge and coke, which will adhere to the exhaust valve plate, suction filter screen, and capillary tube, causing blockage.

- Water entering the system

The water content in the air conditioner system should be controlled below 75 ppm (recommended value).

Ways for water to enter:

Water enters during the manufacturing process of the air conditioner.

The refrigerant contains a lot of water.

System leakage causes the invasion of water.

The compressor is improperly sealed and placed openly.

The vacuum degree of the system does not reach the standard.

Incomplete venting during installation.

- Insufficient oil return in the system

Functions of refrigeration oil:

Lubrication to effectively prevent wear of mechanical parts.

Oil seal function to maintain high and low pressure differences.

Take away the heat generated by friction in time.

If the refrigeration oil cannot return smoothly after being discharged, there will be insufficient oil return in the system, resulting in:

Adverse effects that may occur due to poor oil return:

Poor lubrication leads to wear and seizure of moving parts.

Reduced compressor capacity.

Overheating.

Main reasons for poor oil return:

Excessive refrigerant increases the oil discharge volume.

Inappropriate piping (too long piping and large pipe diameter).

Operation under extremely low temperature conditions.

Short interval between intermittent operations.

Low refrigerant circulation volume and low pressure.

Inappropriate capillary tube. - Overload operation

The compressor has regulations on the maximum operating conditions. If it exceeds the allowable range, the following consequences will occur: - Due to the excessively high exhaust temperature, the surface of the refrigeration oil on the exhaust valve plate is carbonized.

- Due to the excessive high and low pressure difference of the pump body, the blade groove is worn.

- Reduced service life.

- Refrigerant leakage

Due to leakage in the air conditioning system, the refrigerant is reduced. If it operates for a long time in this way, the heat generated by the motor cannot be taken out by the refrigerant. The exhaust temperature will also increase accordingly. When the temperature is too high, R22 begins to thermally decompose to generate acid and water. It will also release carbon in the refrigeration oil to generate carbon deposits. Refrigerant leakage can also lead to poor oil return. - Abnormal power reception

There are many cases where the main coil or secondary coil of the motor is uniformly overheated, which is significantly different from the inter-turn short circuit of the motor itself. Uniform overheating of the motor is generally caused by being impacted by a large external current or being in an overheated state for a long time. Such as abnormal voltage, starting at low temperature and low voltage.

Related Articles

- What Are the Common Causes of Cold Air Blower Noise?

- Air - conditioner Low - pressure Alarm? These Nine Common Causes

- What Are the Causes of Scroll Compressor Damage?

- Causes and Prevention of "Primary Condensation" and "Secondary Condensation" in Fan - Coil Units

- 10 Symptoms and Causes of Abnormal Frosting in Heat Pumps

- Common Causes and Analysis of High and Low Pressure Alarms

- Common Causes and Analysis of Compressor Thermal Protection

- 4 Points on Causes of Water Leakage in Closed Cooling Towers

- Analysis of Causes for Safety Valve Leakage

- What Causes Noise in Pressure Reducing Valves?

- Causes and Solutions for Elevated Pressure in Cold Storage

- Common Causes of Frost Build-up in refrigerant evaporators

- What Causes Poor Refrigeration Effect of Refrigerated Trucks?

- Influence of Fin Spacing of Evaporator in Air Cooler on Frost Formation

- Air - side Economizer

- Winter Approaches: How to Solve the Low High - pressure Issue of Air - cooled Condensing Units?

- How to Troubleshoot and Repair High - pressure Protection of Air - cooled Units?

- What Exactly Are the Ten Typical Malfunctions of Air Conditioners?