Common Fault Repair of Frozen Cold Storage

2024-10-06

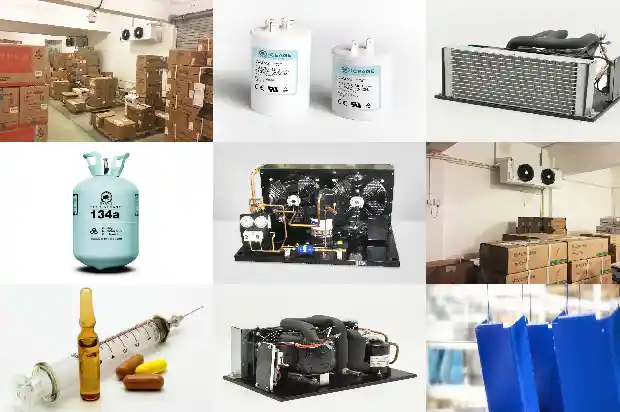

Nowadays, many products need to be frozen and stored, and frozen cold storage can meet such requirements. However, some malfunctions occur during the operation of frozen cold storage. At this time, the cold storage needs to be repaired. Here is an introduction to common frozen cold storage fault repairs.

Common fault repairs for frozen cold storage - 4 common faults and repair methods of cold storage.

Common fault repairs for frozen cold storage - 4 common faults and repair methods of cold storage.

- The cold storage does not cool or has poor cooling effect. Solution: Check whether the condenser of the refrigerator is dirty.

Check whether the evaporator in the warehouse is covered with too thick frost. Check whether the refrigerant leaks (apply soapy water to the pipeline connection. If bubbles are generated, it means that the refrigerant leaks). And ask professionals to replenish the refrigerant and deal with the leakage. Check whether the seal of the cold storage door is intact and eliminate it. Check whether the refrigerator of the cold storage is working. Check whether the parameter settings of the computer controller of the cold storage are correct and readjust them. Check whether the controller of the cold storage is malfunctioning and replace it.

Check whether there is enough gap left for the stacked items in the warehouse and dredge them.

- There is abnormal noise when the machine is running. Repair method: Check the machine to see if it is caused by vibration or mechanical failure. There is abnormal noise in the distribution box. This is the sound emitted by the AC contactor. It is due to reasons such as damage to the contactor, inflexible moving parts of the electromagnet, and dirt on the suction surface of the electromagnet. After power off, press the electromagnet of the contactor back and forth or remove the contactor for cleaning to eliminate the noise.

- When the ambient temperature is too high, after the refrigerator runs for a period of time, the warehouse temperature does not reach the set value and the refrigerator stops in advance. Repair method: This is because the ambient temperature rises and causes the condensing pressure of the refrigerator to be too high. In order to protect the compressor, the machine stops running under the action of the pressure controller. After good heat dissipation, press the black reset button on the pressure controller, and the machine can automatically resume operation.

And check whether the water condenser is well cooled.

Do not adjust the set value on the pressure controller arbitrarily, otherwise the pressure controller will not play a role in protecting the refrigerator.

- The cold storage door is not closed tightly. Solution: Adjust the distance between the hinge and the door lock on the warehouse door and the warehouse body. The adjustment should not be too large, otherwise the warehouse door switch will be very inflexible.

Related Articles

- Basic Faults and Preventive Maintenance of Water - cooled Units

- Composition and Common Faults of Screw Refrigeration Compressors

- Common Faults and Solutions of Central Air - conditioning Chiller Units

- Common Faults of Industrial Chillers

- Common Faults and Corresponding Solutions of Chillers During Use

- Analysis and Troubleshooting of Common Faults in Air - source Heat Pumps

- Maintenance Methods for Faults in Screw Refrigeration Air - conditioner Compressors

- Common Faults and Troubleshooting Methods of the Moving Mechanism of Piston Compressors

- Analysis of Common Faults in Compressor Overcurrent and Burnout

- What are the reasons for the inactivity of the automotive air conditioning compressor? What are the common faults?

- Common Faults of HVAC Fan Coil Units

- Common Operating Faults and Treatment Methods of Centrifugal Compressors

- Common Four Faults and Replacement Methods of Scroll Compressor

- Analysis of Refrigeration Compressor Motor Faults

- Centrifugal Compressor: 5 Common Fault Solutions

- Fault Analysis of Working Principle of Screw Chiller Unit

- Analysis and Treatment of Common Low-Pressure Faults in Chillers

- Analysis and Treatment of Common Low Pressure Faults in Chillers