Common Faults and Daily Maintenance of Commercial Ice Makers

2025-03-09

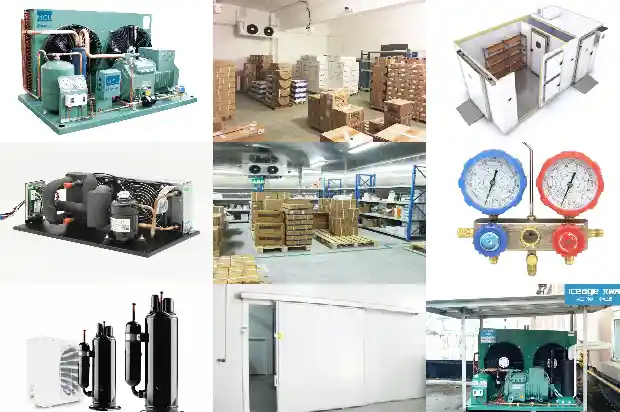

Ice making is the process of cooling water below 0°C and gradually freezing it into ice. In the processes of food processing, cold storage, and transportation, artificial ice, also known as machine-made ice, is often used. The devices for making ice are generally classified into three categories: household ice makers, commercial ice makers, and industrial ice makers.

There are many types of commercial automatic ice makers. According to the shape of the ice, they can be divided into snowflake ice makers, square (block-shaped) ice makers, flake ice makers, etc.

Common Faults and Solutions of Commercial Ice Makers:

- The compressor is working but there is no refrigeration:

(1) Check if the water level in the water pan is insufficient or there is no water.

(2) The speed reducer has a malfunction.

(3) There are ice blockages, dirt blockages, etc. in the refrigeration system.

(4) Check if there are refrigerant leakage points in the system. After patching the leak, add refrigerant liquid;

(5) Check if the solenoid valve is faulty. - The water pump is not working: Check, clean the water pump or replace it.

- The water shortage light is on but it cannot automatically replenish water:

(1) Check the water inlet situation of the pipeline. If there is no water, open the water circuit and restart the machine.

(2) Check the water inlet solenoid valve and replace it if it is faulty. - The water flow in the spray pipe is not smooth, and some ice cubes are incomplete: Check if the holes in the spray pipe of the ice maker are blocked and clean them.

- The power indicator light keeps flashing rapidly, but the machine does not work: Check the connectors of the electrical control system and see if the water temperature probe is loose or has poor contact.

- The ice cubes stick to the plate-shaped evaporator and cannot fall.

Fault causes and solutions:

(1) Check if there is scale on the evaporator (or ice mold). The evaporator needs to be cleaned regularly.

(2) Check if the evaporator is deformed. If it is deformed, replace the evaporator.

(3) Check if the refrigeration system is short of refrigerant and if there is a leakage. Patch the leak and replenish the refrigerant.

(4) The defrost solenoid valve is not working: Repair or replace the high-pressure bypass solenoid valve.

(5) The ice cubes are stuck with the water baffle switch: Adjust the ice thickness switch to make the ice layer appropriate and adjust the position of the main board.

(6) The water temperature probe malfunctions: Use a multimeter to measure the resistance value of the water temperature probe. If the resistance value is above 27K, it is judged that the controller is broken and should be replaced. If the resistance value is lower than 27K, any one of the two wires must be disconnected, and the resistance value should be adjusted to between 27K and 28K by connecting a resistor in series. - The ice maker makes ice slowly and the ice is unevenly made. Reasons and solutions:

(1) The ambient temperature is too low. When the ambient temperature is lower than the applicable temperature range of the machine, both the evaporation temperature and the condensation temperature decrease, the superheat of the evaporator increases, the refrigeration capacity is low, and the ice-making speed is slow. The ice maker can be moved to an environment with a relatively higher temperature for use.

(2) There may be insufficient refrigerant or a leakage in the refrigeration system.

(3) Some ice makers have a liquid storage tank, which can automatically adjust the working state. If there is no liquid storage tank, an excessive amount of refrigerant will also lead to slow ice making. If the refrigerant used is R22, measure the low pressure, which should be below 0.25MPA. If it is higher than 0.3MPA, it will be difficult to make ice. - The made ice flakes are not hard enough and the surface is soft:

(1) The ambient temperature is too high.

(2) Too much refrigerant has been added.

(3) The water supply is too large.

(4) The compressor power is insufficient. - The compressor works intermittently:

(1) Check the power supply situation and whether the voltage is too low.

(2) Whether the system has a pressure protection. For example, if the condenser is too dirty, a high-pressure protection occurs. - The ice maker makes excessive noise:

(1) Check if the fan is faulty.

(2) Check if the speed reducer is faulty.

(3) Check if the noise of the compressor is abnormal. - The system failure is reported when the machine is turned on:

(1) Check if the phase sequence is correct.

(2) Whether the power supply system has a fault.

(3) Whether the control board is faulty. - The ice maker leaks water: It may be that the water supply of the water inlet valve is too large, or the connecting water pipe is damaged, the pipe clamp is faulty, or the water level float valve is faulty. It is necessary to check and eliminate them one by one.

- The ice production is low:

(1) The capillary tube or the expansion valve is blocked.

(2) There is an ice blockage in the refrigeration system.

(3) There is insufficient refrigerant or a leakage. - Water shortage alarm:

(1) Check if the filter screen of the water supply joint, the water supply pipe, the water inlet valve, etc. are blocked.

(2) Check if the drain valve is leaking.

(3) Check if the water pump is faulty. - The motor is burned out:

(1) Check if the ice blade bearing is broken and replace the ice blade bearing if necessary.

(2) Check if the speed reducer is stuck inside or the transmission shaft is broken, and replace the speed reducer in time.

Precautions for Use and Daily Maintenance of the Ice Maker:

(1) Before use, carefully read the installation and use instructions of the ice maker, and check whether the circuit voltage and the water pressure of the water pipe meet the regulations. The users or maintenance personnel of the equipment should understand the product structure, characteristics, and maintenance knowledge.

(2) Leave an appropriate space around the ice maker, not less than 250-300mm, to ensure good heat dissipation and ventilation around the machine. Do not place equipment with strong heat sources nearby.

(3) Regularly clean the water circuit system such as the water pipe, water tank, spray nozzle, filter screen, and ice storage box.

(4) Regularly clean the oil stains and dust on the surface of the condenser.

(5) When cleaning the ice maker, turn off the power supply. It is strictly prohibited to directly rinse the body with a water pipe. Use a neutral detergent to scrub, and it is strictly prohibited to use corrosive solvents such as acidic and alkaline solvents for cleaning.

(6) Regularly check if the bolts of the speed reducer are loose or if the operation and rotation are smooth and stable.

(1) Before use, carefully read the installation and use instructions of the ice maker, and check whether the circuit voltage and the water pressure of the water pipe meet the regulations. The users or maintenance personnel of the equipment should understand the product structure, characteristics, and maintenance knowledge.

(2) Leave an appropriate space around the ice maker, not less than 250-300mm, to ensure good heat dissipation and ventilation around the machine. Do not place equipment with strong heat sources nearby.

(3) Regularly clean the water circuit system such as the water pipe, water tank, spray nozzle, filter screen, and ice storage box.

(4) Regularly clean the oil stains and dust on the surface of the condenser.

(5) When cleaning the ice maker, turn off the power supply. It is strictly prohibited to directly rinse the body with a water pipe. Use a neutral detergent to scrub, and it is strictly prohibited to use corrosive solvents such as acidic and alkaline solvents for cleaning.

(6) Regularly check if the bolts of the speed reducer are loose or if the operation and rotation are smooth and stable.

Related Articles

- Analysis of Common Faults of Chillers

- Wiring Methods, Faults and Classifications of Fan Coil Units, All Here~~

- Eliminate the "Blockage" Faults (Ice Blockage, Dirt Blockage, Oil Blockage) of the Refrigeration System in 5 Minutes

- How to Inspect and Troubleshoot the Faults of the Control Valve in the Cold Storage?

- Common Faults in Refrigeration Systems and Handling Methods

- What Are the Common Causes of High - pressure Faults in Chillers?

- Basic Faults and Preventive Maintenance of Water - cooled Units

- Composition and Common Faults of Screw Refrigeration Compressors

- Common Faults and Solutions of Central Air - conditioning Chiller Units

- Common Faults of Industrial Chillers

- Common Faults and Corresponding Solutions of Chillers During Use

- Analysis and Troubleshooting of Common Faults in Air - source Heat Pumps

- Maintenance Methods for Faults in Screw Refrigeration Air - conditioner Compressors

- Common Faults and Troubleshooting Methods of the Moving Mechanism of Piston Compressors

- Analysis of Common Faults in Compressor Overcurrent and Burnout

- What are the reasons for the inactivity of the automotive air conditioning compressor? What are the common faults?

- Common Faults of HVAC Fan Coil Units

- Common Operating Faults and Treatment Methods of Centrifugal Compressors