Cooling fan introduction of the fan

2024-08-27

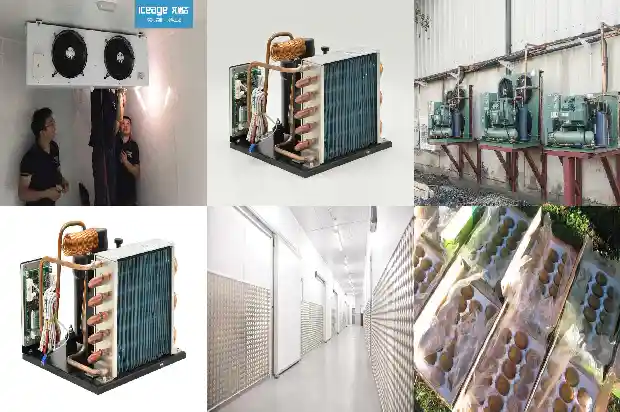

In some small and medium-sized cold storages, through the combined use of air coolers and refrigeration units, chilled or frozen goods in the warehouse are refrigerated, or items are frozen. The air cooler, professionally known as an air cooler for refrigeration. In the structure of the air cooler, there is an important component called "fan". Through the flapping of fan blades, the air in the cold storage exchanges heat with the evaporator, thereby realizing the cooling of the ambient temperature. That is, the fan plays a role in forced circulation of the air.

The fan is a device for conveying air or gas composed of an impeller (blades), a motor and a casing. There are many types of fans. Common fans in air conditioning, ventilation systems, and industrial production include axial flow fans, centrifugal fans, and cross-flow fans. Among them, the axial flow fan is composed of an impeller, fixed blades and a casing. The air flow flows along the axial direction and is a fan driven by a belt or directly connected. The centrifugal fan is composed of a rotor or impeller, a diffuser and a volute.

For general-purpose axial flow fans, structurally, there are motor-direct-connected type, coupling-driven type and belt-driven type.

The blades of the impeller are generally evenly distributed.

The air coolers used in small and medium-sized cold storages generally use low-noise and energy-saving fans. The fans are marked with signs indicating the rotation direction of the impeller. The noise of the fans is measured before leaving the factory and complies with the provisions of relevant national standards. Before the air cooler operates, the condition of the fan should be checked first: observe that the fan blades are intact and undamaged, the blades rotate flexibly, operate smoothly and lightly, without abnormal noise, jamming and other phenomena, and there is no oil leakage at the bearing part. When in use, the grounding wire of the motor and the grounding of the external device should be effectively connected.

When selecting a fan, in addition to considering the external dimensions, current, power, air volume, static pressure and rotation speed, it is also necessary to consider its use environment, noise, etc. Air volume refers to the volume flow rate of gas conveyed by the fan in unit time, also known as flow rate. Generally, it refers to the amount of gas conveyed in working condition. When selecting a type, the air volume required by the system is considered first.

Common faults of axial flow fans are:

- The fan does not rotate. Check whether the power is connected.

- If the noise is loud, check the bearing lubricating oil condition, or check whether there is foreign matter in the fan and remove the foreign matter.

- If the motor of the fan does not work, check the motor wiring.

- Check for oil leakage or damage to the sealing ring.

- If the vibration is too large, check whether there is deposited dirt on the blades and clean it; check whether the casing and impeller components are deformed, and whether the connection between the impeller and the shaft sleeve is loose.

- Whether the filter screens at the air inlet and outlet are blocked and the filter screens need to be cleaned.

- If the ambient temperature is high, it is necessary to increase the environmental ventilation and heat dissipation.

- If the temperature at the air inlet is too high, it is necessary to reduce the temperature at the air inlet.

Related Articles

- Causes and Prevention of "Primary Condensation" and "Secondary Condensation" in Fan - Coil Units

- What Should Be Done When the Condenser Fan Doesn't Rotate During Operation?

- How to Choose the Bearings of Cooling Fans?

- What are the characteristics and application fields of cross-flow fans?

- How to Choose an Air Purifier Cooling Fan

- Common Faults of HVAC Fan Coil Units

- Introduction to Inspection and Handling Methods for Refrigerant Leak in Cold Storage

- Introduction to Control Valves in Refrigeration Systems

- Introduction to Basic Types of Cold Storage

- Introduction to Lithium Bromide Absorption Chillers

- Introduction to the Advantages of Dual - temperature Cold Storage

- Introduction to Various Water Tanks in Air - conditioning Systems

- Introduction to the Cleaning Processes and Methods of Heat Exchangers and Cooling Towers

- Introduction to Six Kinds of Two-stage Compression Refrigeration Systems

- Introduction to Key Points of Compressor Grouping in Quick-freezing Cold Storage

- Introduction to the Construction and Features of Cold Storage in Cold Chain Logistics

- All-round Introduction to Condensers and Evaporators!

- Introduction to Vapor Barrier of Cold Storage and Moisture Protection of Equipment