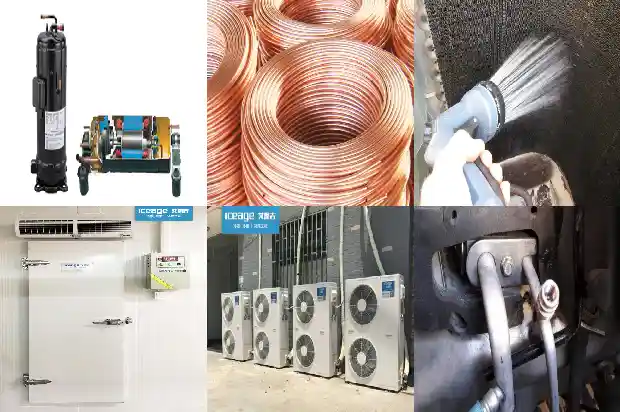

Essential Basics for Maintenance, Debugging of Refrigeration and Air - conditioning Systems

2025-01-08

There are many methods of refrigeration, and the commonly used ones are:

Gas expansion refrigeration, liquid vaporization refrigeration, vortex tube refrigeration, and thermoelectric refrigeration.

Among them, liquid vaporization refrigeration is the most widely used. Its working principle is to utilize the heat absorption during the vaporization of the liquid to achieve refrigeration.

Gas expansion refrigeration, liquid vaporization refrigeration, vortex tube refrigeration, and thermoelectric refrigeration.

Among them, liquid vaporization refrigeration is the most widely used. Its working principle is to utilize the heat absorption during the vaporization of the liquid to achieve refrigeration.

- Working principle of air conditioner

After entering the oil separator, the working fluid gas enters the oil separator to separate the lubricating oil from it, and the lubricating oil flows down along the inner wall of the cylinder.

The working fluid gas is led out of the oil separator through the central tube by the porous baffle.

The separated lubricating oil is concentrated at the bottom of the oil separator. It can be drained regularly, or a float valve can be used to make the lubricating oil automatically return to the crankcase of the compressor.

Drier-filter:

The function of the drier-filter is to absorb the moisture in the refrigeration system and block the impurities in the system to prevent them from passing through, thus preventing ice blockage and dirt blockage in the refrigeration system pipelines.

Since the most easily blocked part of the system is the capillary tube (or expansion valve), the drier-filter is usually installed between the condenser and the capillary tube (or expansion valve).

Liquid receiver:

During the operation of the refrigeration system, due to changes in working conditions or adjustments to the refrigeration capacity, the circulation volume of the refrigerant in the system will change.

By setting up a liquid receiver, the liquid storage capacity of the liquid receiver can be used to balance and stabilize the refrigerant circulation volume in the system, enabling the refrigeration system to operate normally.

In addition, when a component in the refrigeration system fails and needs to be disassembled and repaired, the refrigerant in the system can be recovered into the liquid receiver through certain operating methods.

The liquid receiver is generally set between the condenser and the throttling element to allow the refrigerant liquid in the condenser to smoothly enter the liquid receiver. The position of the liquid receiver should be lower than that of the condenser.

Electromagnetic four-way reversing valve:

After the electromagnetic coil is energized, it changes the action direction of the valve block in the valve body, thereby changing the flow direction of the refrigerant.

Thus, the purpose of refrigeration or heating can be achieved.

Solenoid valve:

The solenoid valve is usually installed in front of the expansion valve to directly control the amount of refrigerant entering the evaporator. It can also be installed in front of the compressor unloading cylinder to control the unloading of the compressor cylinder.

It is divided into two types:

Direct - opening and closing solenoid valve;

Indirect solenoid valve.

Check valve:

The check valve is usually connected in parallel with the auxiliary capillary tube, and the two are then connected in series with the main capillary tube.

The check valve is a tubular component with a movable spherical or hemispherical plug made of stainless steel or nylon inside the tube.

Combined with the capillary tube, it can adapt to two different operating conditions of refrigeration and heating. - Types and states of refrigerants

The main refrigerants for air conditioners are R22, R410A, and R32.

R22 is a medium - temperature refrigerant. Its standard boiling point is about - 40.8 °C. The solubility of water in R22 is very small, and it is mutually soluble with mineral oil. R22 is non - flammable, non - explosive, has low toxicity, and strong penetration ability.

R410A is an HFC refrigerant composed of R32 and R125 in a mass fraction ratio of 50% each. It belongs to a near - azeotropic mixture, and its thermodynamic properties are very close to those of a single working fluid. Compared with R22, the condensing pressure of R410A increases by 1.6 times. It is a high - pressure refrigerant, and the pressure resistance of the system needs to be improved.

R32 is short for difluoromethane. It is a coolant with zero ozone depletion potential. It is a gas at room temperature and a colorless and transparent liquid under its own pressure. It is easily soluble in oil and difficult to dissolve in water. It is an energy - saving, carbon - reducing, environmentally friendly, and non - toxic refrigerant, but it is flammable and explosive!

Three states of refrigerants: saturation, superheat, and sub - cooling

Saturated refrigerant:

In a saturated refrigerant, the vapor - liquid conversion is in dynamic equilibrium. At this time, both the liquid and the gas are in a saturated state.

There is a one - to - one correspondence between the saturated temperature and the saturated pressure. The saturated pressure increases as the saturated temperature rises. If one of them changes, the other will also change accordingly. In the system, the refrigerant in the evaporator absorbs heat, and the refrigerant in the condenser releases heat. In these places, the refrigerant is in a saturated state.

Degree of superheat:

Under a certain pressure, the value by which the temperature of superheated steam exceeds the saturated temperature.

Superheated refrigerant:

In a superheated refrigerant, the temperature of the refrigerant gas is higher than the saturated temperature corresponding to the saturated pressure. Superheat occurs only after the liquid refrigerant has evaporated. In the case of superheat, there is no one - to - one correspondence between the temperature and pressure of the refrigerant gas.

Near the outlet of the evaporator, after the refrigerant has completely evaporated, it continues to absorb heat and becomes a superheated refrigerant with a temperature higher than the saturated temperature. The refrigerant enters the compressor through the suction pipe in a superheated state.

Sub - cooled refrigerant:

In a sub - cooled refrigerant, the temperature of the refrigerant liquid is lower than the saturated temperature corresponding to the saturated pressure. Sub - cooling occurs only when there is no vapor in the flowing refrigerant. In the case of sub - cooling, there is no one - to - one correspondence between the temperature and pressure of the refrigerant liquid.

Between the outlet of the condenser and the throttle valve, after the refrigerant condenses into a saturated liquid, it may continue to release heat and cool down to become a sub - cooled refrigerant.

Related Articles

- HVAC Design | Basics of Cooling Towers

- Basic Faults and Preventive Maintenance of Water - cooled Units

- Essential for Maintenance! Parameters and Phenomena of Normal Operation of Refrigeration and Heating Systems

- Welding Equipment Used in Refrigeration System Maintenance

- Maintenance Methods for Small Modular Cold Storage Failures

- Maintenance Techniques for Air - conditioning Refrigeration Systems

- Maintenance Strategies for the Working Cycle and Electrical Automatic Control of Chillers

- 8 Maintenance Procedures for Industrial Chillers

- Requirements and Maintenance for Building Meat Food Cold Storage

- Maintenance Methods for Faults in Screw Refrigeration Air - conditioner Compressors

- Maintenance Methods for Refrigerant Leak in Air - conditioner Outdoor Unit

- Knowledge, Installation and Maintenance of Cold Storage Systems

- Are you familiar with the detection and maintenance methods of air conditioner components?

- Maintenance and Operation of Freezing and Cold Storage Warehouses

- Water-cooled Screw Chiller: Operation and Maintenance

- Daily Maintenance Training for Users after Installation of Small and Medium-Sized Cold Storages

- Maintenance of Screw Chiller

- Maintenance of Screw Chiller