How to Check Refrigerant Leakage in Air Conditioning System?

2024-10-10

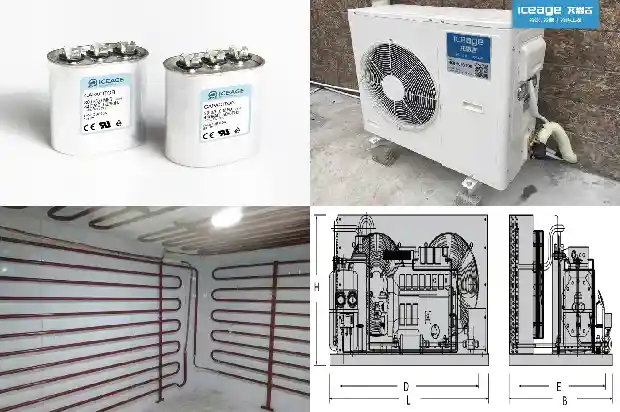

The refrigeration system of an air conditioner is composed of a compressor, condenser, four-way reversing valve, throttler, and evaporator.

- Visual inspection: When oil stains are found at a certain place in the system by visual inspection, this place may be a leakage point. Visual leak detection is simple and easy to perform and has no cost, but it has great drawbacks. Unless it is a large leak point where the system suddenly breaks and the system is leaking liquid colored medium, visual leak detection cannot locate the leak point because usually the leakage place is very subtle and there are many parts of household air conditioners that are almost invisible.

- Dishwashing liquid or washing powder mixed water leak detection: Inject 10 - 20 kg/cm2 pressure nitrogen into the system, and then apply soapy water to various parts of the system. The bubbling place is the leakage point.

This method is currently the most common leak detection method, but a person's arms are limited and a person's visual range is limited. In many cases, the leak point cannot be seen at all.

- Nitrogen water leak detection: Inject 10 - 20 kg/cm2 pressure nitrogen into the system and immerse the system in water. The bubbling place is the leakage point. This method is essentially the same as the previous soapy water leak detection method. Although it has a low cost, it has obvious disadvantages: The water used for leak detection is easy to enter the system, causing corrosion of the materials in the system. At the same time, high-pressure gas may also cause greater damage to the system. The labor intensity during leak detection is also very high, which increases the cost of maintenance and repair.

- Fluorescent leak detection: It uses the principle that fluorescent leak detection agents will emit bright yellow-green light under the irradiation of ultraviolet/blue light leak detection lamps to detect fluid leakage in various systems. When in use, only add the fluorescent agent to the system in a certain proportion. After the system operates for 20 minutes, wear special glasses and irradiate the outside of the system with a leak detection lamp. The leakage place will show yellow fluorescence.

- Gas pressure difference leak detection: Utilize the air pressure difference inside and outside the system, amplify the pressure difference through a sensor, and express the leak detection result in the form of numbers, sounds, or electronic signals. This method can only "qualitatively" know whether the system is leaking but cannot accurately find the leak point.

- Electronic leak detection: Move the probe to places where there may be leakage. When the leak detection device issues an alarm, it indicates that there is a large amount of leakage here. Electronic leak detection products are easily damaged, complex to maintain, and easily affected by environmental chemicals such as gasoline and exhaust gas, and cannot accurately locate the leak point.

Related Articles

- What to Consider When Replacing R22 with Refrigerant R404A?

- Introduction to Inspection and Handling Methods for Refrigerant Leak in Cold Storage

- Four Combustible and Explosive Refrigerants: Precautions When in Use!

- Characteristics and Differences among Water System, Air System and Refrigerant System

- How to Judge the Refrigerant Charge Amount?

- How to Properly Extract Ammonia Refrigerant during Refrigeration Parts Repair

- Operating Principle and Standard Installation Steps of Multi - split Systems in Refrigerant Air - conditioning Systems

- Sensor for Refrigerant Leak Detection in Cold Chain Transportation

- Why Should Refrigerant Be Filled in Liquid Form? What Are the Filling Methods?

- What are the Cooling and Heating Pressures of an Air Conditioner? How to Calculate the Optimal Refrigerant Quantity?

- Maintenance Methods for Refrigerant Leak in Air - conditioner Outdoor Unit

- Operations and Precautions for Multi - split Air Conditioners: Blowing Debris, Air Tightness, Vacuum Drying, and Refrigerant Charging

- Multi-split air conditioner: Nitrogen charging for welding, pressure maintaining, vacuuming and refrigerant charging

- What Sensors Are Used for Leak Detection of R1234yf, the New Generation of Environmentally Friendly Refrigerant?

- Scheme for the Use and Safety of Ammonia Refrigerants

- Precautions for Replacing Refrigeration Compressor Refrigerant Oil

- Introduction to the Relationship between Refrigerants and Cold Storage Temperatures

- Determining the Adequacy of Refrigerant Dosage in Fluorine Refrigeration Systems