How to Install the Purple Copper Tubes Special for Air Conditioners

2024-11-17

The refrigeration systems in refrigeration air conditioners generally use non-ferrous metal materials such as copper and aluminum. During the manufacturing, installation, and maintenance processes, the welding of pipes is a crucial link.

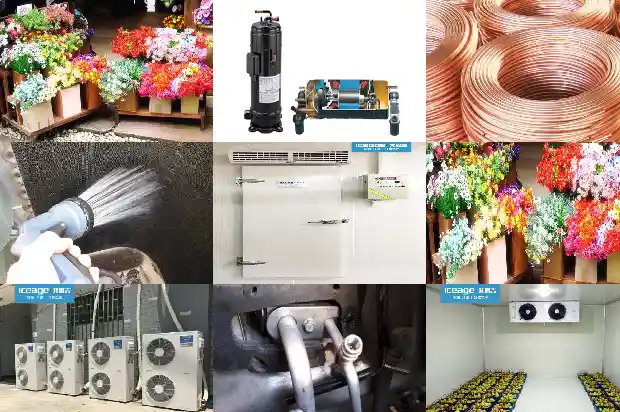

The purple copper pipe for air conditioners refers to the connecting copper pipe that links the indoor unit and the outdoor unit of the air conditioner. The purple copper pipe for air conditioners has the characteristics of being hard in texture, not easy to corrode, and being resistant to high temperatures and high pressures, so it is deeply loved by people. The special purple copper pipes for air conditioners can be divided into two types: ordinary air conditioner copper pipes and degreased air conditioner copper pipes. Of course, they can also be classified according to the uses of the purple copper pipes for air conditioners into R22 air conditioner copper pipes, R410A central air conditioner copper pipes, capillary copper pipes, special-shaped copper pipes, etc. When air conditioners are installed, new refrigerant air conditioners all use special R410A air conditioner copper pipes to connect the outdoor units and indoor units of the air conditioners. And the welding of the R410A copper pipes for air conditioner connecting pipes is directly a factor that affects the refrigeration effect. The correct operation steps are very important. For the welding of copper pipes to copper pipes, the general welding steps should be strictly followed during the operation. Otherwise, the quality of welding will be affected.

Preparation and Piping

- Check whether the amounts of oxygen and acetylene in the cylinders are sufficient.

- Check the requirements on the drawings to ensure that all components are complete without any shortage and in good working condition.

- Ensure that the pipelines are horizontally and vertically straight, and pay attention to the directionality of each valve component.

- According to the dimensions and pipe diameters required by the drawings, use a tape measure to measure the corresponding lengths and mark the positions with a wire numbering pen.

- For thicker copper pipes, they should be fixed first and then removed with a cutting tool. Ensure that the cut edges are flat and without deformation.

- Use a file to file the burrs on the cut edges flat and wipe them clean with a rag.

- Clean the surfaces of the pipe fittings to be welded or flare them. The flared bell mouths should be smooth, round, without burrs and cracks, with uniform thickness. Use sandpaper to grind the joint parts of the copper pipes to be welded clean, and finally wipe them clean with a dry cloth. Otherwise, it will affect the flow of solder and the welding quality.

- Except for the welding of copper to copper, all pipe fittings should be cleaned with gauze or a stainless steel wire brush before welding to expose the bright metal surfaces. (Both the inner and outer surfaces should be cleaned, and metal scraps and sand grains should be removed completely.)

- Insert the copper pipes to be welded into each other overlapping (pay attention to the dimensions) and align the centers.

- See the table for the insertion depth and clearance between copper pipe joints and copper pipes. (The insertion depth is approximately equal to the pipe diameter.)

Protection

- During welding, low-speed nitrogen should be passed through the welded pipe to prevent oxidation.

- Acetylene gas should pass through an oxidation-free welding generator to prevent the outer surfaces of the welded objects from being oxidized.

Welding

- During welding, the parts to be welded must be preheated. Heat the welding part of the copper pipe with the flame. When the copper pipe is heated to a purplish-red color, move the flame away and then place the solder against the weld joint. After the solder melts, it will flow into the welded copper parts. The temperature after heating can be reflected by the color. Dark red: about 600 degrees Celsius; Deep red: about 700 degrees Celsius; Orange-red: about 1000 degrees Celsius.

- During welding, the gas welding flame should not directly heat the welding rod.

- For components that are prone to deformation and damage under high-temperature conditions, corresponding protective measures should be taken. For example, angle valves, evaporators, condensers, etc. should be wrapped with wet gauze at the joints before welding. For solenoid valves, expansion valves, liquid mirrors, four-way valves, those that can be disassembled must be disassembled before welding, and those that cannot be disassembled should also take the above measures.

- During welding, when annealing the copper pipes after welding, the annealing temperature should not be lower than 300 degrees Celsius.

- After welding, cool it down and use dry nitrogen to clean the oxides and welding slag inside the pipes.

Rewelding

- If leakage is found in the welding during the pressure test process, rewelding should be carried out. When rewelding, the nitrogen used for system pressure testing should be released, and the pressure test should be repeated after welding.

- Before rewelding, wipe the oxide layer on the surface clean with gauze.

After rewelding, the oxide scale should be removed completely. After quenching in water, the copper pipes should be dried, and there should be no water droplets.

- After all welding is completed, use nitrogen to blow the system clean.

Summary of Welding Steps

- Prepare the gases, equipment, and materials for welding;

- Put on protective gear properly;

- Check the status of the equipment and tools for welding;

- Open the cylinder valves, adjust the oxygen pressure reducer to control the outlet pressure at 0.15 - 0.2 MPa, and adjust the acetylene pressure reducer to control the outlet pressure at 0.01 - 0.02 MPa;

- Open the acetylene regulating valve - ignite - adjust the acetylene regulating valve to make the flame length moderate;

- Open the oxygen regulating valve - slowly adjust to make the flame a neutral flame;

- Adjust the flame in the order of neutral flame (small) → add acetylene → the feathery flame becomes larger → add oxygen → adjust to a neutral flame (large);

- Adjust the flame in the order of neutral flame (large) → reduce oxygen → the feathery flame appears → reduce acetylene → adjust to a neutral flame (small);

- Make the tip of the flame core 2 - 4 mm away from the welded parts, perpendicular to the pipe, and evenly heat the entire length of the weld joint to a dark red color;

- Apply the flux. When the flux becomes a transparent liquid and evenly wets the weld joint, send the solder coated with the flux for heating until the solder melts fully and fills the weld joint abundantly;

- Remove the flame and keep the welded parts from being misaligned with each other before the solder is completely solidified;

- Close the acetylene valve and then close the oxygen valve to extinguish the flame;

- Loosen the pressure reducer and close the cylinder valve;

- Tidy up the tools and equipment and clean the site.

Related Articles

- What Special Requirements are There for the Installation of Tea Cold Storage?

- Explosion-Proof Refrigerators' Special Characteristics

- Influence of Fin Spacing of Evaporator in Air Cooler on Frost Formation

- Air - side Economizer

- Winter Approaches: How to Solve the Low High - pressure Issue of Air - cooled Condensing Units?

- What Are the Common Causes of Cold Air Blower Noise?

- How to Troubleshoot and Repair High - pressure Protection of Air - cooled Units?

- What Exactly Are the Ten Typical Malfunctions of Air Conditioners?

- What Misconceptions Should Be Avoided in Low - temperature Refrigeration System Repairs

- Practical Knowledge on Freeze Protection of Air - conditioning Equipment

- Remember! 3 Steps to Calculate Central Air - conditioner Cooling Capacity

- How to Read the High - and Low - Pressure Gauges of Refrigeration Air - conditioners?

- Analysis of Seven Reasons for Ice Formation in Computer Room Air Conditioners

- Air - conditioner Low - pressure Alarm? These Nine Common Causes

- Selection of Bypass Control Valves for Air - conditioning Water Systems

- Common Faults and Solutions of Central Air - conditioning Chiller Units

- Could a Tiny Copper Tube Cause a Multi - split Air Conditioner to Stop Cooling? Refrigeration Workers Must Pay Attention!

- Maintenance Techniques for Air - conditioning Refrigeration Systems