Influence of Fin Spacing of Evaporator in Air Cooler on Frost Formation

2025-02-20

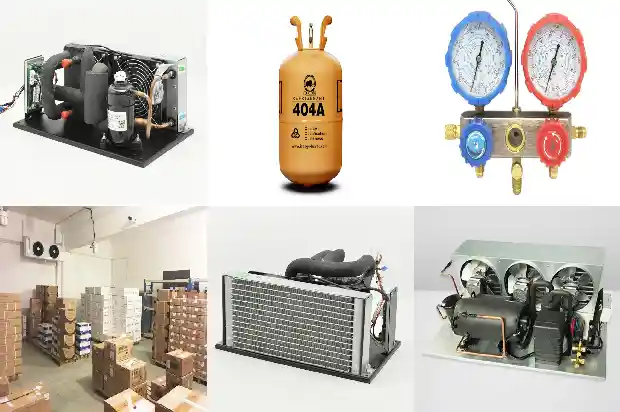

As a commonly used evaporator in the refrigeration system, whether the air cooler is properly selected directly affects the efficiency of the refrigeration system. As is known to all, air coolers adopt different fin spacings according to different required ambient temperatures.

For the air coolers we commonly see, the fin spacings include 4mm, 4.5mm, 6 - 8mm, 10mm, 12mm, and there are also those with variable fin spacings at the front and back. A smaller fin spacing is suitable for high - temperature environments; the lower the temperature of the cold storage, the larger the required fin spacing.

Based on engineering experience, for environments with temperatures ranging from 0℃ to 20℃, such as workshop air - conditioners, cool storage rooms, cold storage corridors, fresh - keeping storages, controlled - atmosphere storages, and ripening storages, air coolers with a fin spacing of 4mm or 4.5mm are selected; for environments with temperatures from - 16℃ to - 25℃, such as low - temperature freezing and refrigeration storages, and low - temperature logistics storages, air coolers with a fin spacing of 6mm - 8mm are chosen; for quick - freezing storages with temperatures from - 25℃ to - 35℃, air coolers with a fin spacing of 10mm and 12mm are generally selected. If the goods to be quickly frozen have high humidity, an air cooler with variable fin spacing will be chosen, and the fin spacing on the air - inlet side can reach 16mm.

However, in some cases, the fin spacing of the air cooler cannot be selected solely based on the temperature. For example, in the rapid precooling and acid - removal processes of meat and vegetables, although the temperature of the cold room is generally set above 0℃, due to the high incoming - goods temperature, fast cooling speed, and high humidity of the goods, it is not suitable to select an air cooler with a fin spacing of 4mm or 4.5mm. An air cooler with a fin spacing of 8mm or even 10mm must be used.

There are also fresh - keeping storages similar to those for storing fruits and vegetables such as garlic and apples. The suitable storage temperature is generally around - 2℃. For fresh - keeping or controlled - atmosphere storages with a storage temperature lower than 0℃, an air cooler with a fin spacing of not less than 8mm also needs to be selected to avoid the rapid frosting that could block the air duct and increase power consumption.

The influence of frost on the refrigeration system:

When the refrigeration system of the cold storage is operating normally, the surface temperature of the evaporator is much lower than the dew - point temperature of the air, and the moisture in the air will precipitate and condense on the pipe wall. If the pipe - wall temperature is lower than 0°, the water droplets will condense into frost. Frost formation is also the result of the normal operation of the refrigeration system, so a small amount of frost is allowed on the surface of the evaporator.

When the refrigeration system of the cold storage is operating normally, the surface temperature of the evaporator is much lower than the dew - point temperature of the air, and the moisture in the air will precipitate and condense on the pipe wall. If the pipe - wall temperature is lower than 0°, the water droplets will condense into frost. Frost formation is also the result of the normal operation of the refrigeration system, so a small amount of frost is allowed on the surface of the evaporator.

Because the thermal conductivity of frost is too small, only one - hundredth or even one - several - hundredth of that of metal, the frost layer forms a relatively large thermal resistance. Especially when the frost layer is thick, it is like insulation, making it difficult for the cold in the evaporator to be released, affecting the refrigeration effect of the evaporator, and ultimately preventing the cold storage from reaching the required temperature. At the same time, the evaporation of the refrigerant in the evaporator will also be weakened. Incompletely evaporated refrigerant may be sucked into the compressor, causing a liquid - hammer accident.

Related Articles

- Influence of Condensing Temperature Variation on Vapor Compression Refrigeration System

- Fin Spacing Design of Cooler and Several Knowledge Points of Defrosting in Cold Storage

- Liquid Level Detection and Control of Flooded Evaporators

- Technology: Dry, Flooded and Falling Film Evaporators!

- All-round Introduction to Condensers and Evaporators!

- Common Causes of Frost Build-up in refrigerant evaporators

- Evaporator Three Ways of Feeding Liquids

- Air - side Economizer

- Winter Approaches: How to Solve the Low High - pressure Issue of Air - cooled Condensing Units?

- What Are the Common Causes of Cold Air Blower Noise?

- How to Troubleshoot and Repair High - pressure Protection of Air - cooled Units?

- What Exactly Are the Ten Typical Malfunctions of Air Conditioners?

- What Misconceptions Should Be Avoided in Low - temperature Refrigeration System Repairs

- Practical Knowledge on Freeze Protection of Air - conditioning Equipment

- Remember! 3 Steps to Calculate Central Air - conditioner Cooling Capacity

- How to Read the High - and Low - Pressure Gauges of Refrigeration Air - conditioners?

- Analysis of Seven Reasons for Ice Formation in Computer Room Air Conditioners

- Air - conditioner Low - pressure Alarm? These Nine Common Causes