Introduction: Ten Key Points Every Refrigeration Professional Should Know

2025-04-04

Four elements - temperature, humidity, cleanliness, and air distribution. Adjusting these four elements can control the indoor environment to meet comfort requirements.

Temperature: Cooling and heating the indoor air. This is a common requirement of users for air conditioners.

Humidity: Dehumidifying/humidifying the moisture in the air. Humidity affects the perception of heat and cold and ensures the operating environment and conditions of various devices.

Cleanliness: Removing sand and dust from the air to make it clean. This is related to human health. Additionally, special occasions such as medical settings have high requirements for cleanliness.

Air Distribution: Circulating air to reach every corner of the room. It mainly includes two aspects: air circulation and air velocity.

Comfortable Environment - Cold Shock: During summer cooling, when the temperature difference between indoors and outdoors reaches 10 °C, people will strongly feel the cold and hot air when entering and leaving the room, causing discomfort to the body. This discomfort is called "cold shock".

When cooling, the temperature difference between indoors and outdoors should be 3 - 7 °C (the standard is 5 °C).

Under no circumstances should the temperature difference exceed 10 °C.

When cooling, the temperature difference between indoors and outdoors should be 3 - 7 °C (the standard is 5 °C).

Under no circumstances should the temperature difference exceed 10 °C.

Temperature and Humidity: In the same room, the larger the temperature difference between the dry - bulb temperature and the wet - bulb temperature, the smaller the relative humidity of the measured room.

Load: The capacity of air - conditioning equipment required for a room mainly depends on the room load.

Cooling Capacity and Heating Capacity: The cooling capacity, also known as the refrigeration capacity, is the amount of heat transferred from a low - temperature object to a high - temperature object by a refrigeration machine (air conditioner) per unit time.

The amount of heat generated by an air conditioner per unit time (electric - heating type) or the amount of heat that the air conditioner absorbs from the outside and delivers to the room after heat absorption (heat - pump type) is called the heating capacity.

The amount of heat generated by an air conditioner per unit time (electric - heating type) or the amount of heat that the air conditioner absorbs from the outside and delivers to the room after heat absorption (heat - pump type) is called the heating capacity.

Unit: The standard unit is watt (W) or kilowatt (kW).

1W = 0.

Ton of Refrigeration: The refrigeration capacity corresponding to the change of 1t of 0 °C water into 0 °C ice within 1 day and night (24h).

The ton of refrigeration is divided into the US ton of refrigeration and the Japanese ton of refrigeration.

1 US ton of refrigeration = 3024kcal/h = 3.526kW;

1 Japanese ton of refrigeration = 3320kcal/h = 3.860kW.

1W = 0.

Ton of Refrigeration: The refrigeration capacity corresponding to the change of 1t of 0 °C water into 0 °C ice within 1 day and night (24h).

The ton of refrigeration is divided into the US ton of refrigeration and the Japanese ton of refrigeration.

1 US ton of refrigeration = 3024kcal/h = 3.526kW;

1 Japanese ton of refrigeration = 3320kcal/h = 3.860kW.

Power Consumption:

TC: Total capacity (cooling capacity or heating capacity under the corresponding ratio and indoor design temperature), kW

PI: Input power (power consumption required to produce the corresponding cooling or heating capacity), kW

When calculating the input power of an air - cooled air - conditioning main unit, the power of the fan motor should be added.

TC: Total capacity (cooling capacity or heating capacity under the corresponding ratio and indoor design temperature), kW

PI: Input power (power consumption required to produce the corresponding cooling or heating capacity), kW

When calculating the input power of an air - cooled air - conditioning main unit, the power of the fan motor should be added.

MCA, MFA

Professional Terms (Split Air Conditioners)

IPLV(C) comprehensively reflects the operating efficiency of multi - connected units under partial load. Tested according to a unified method, it can more fairly and reasonably reflect the energy - saving performance of multi - connected unit products! This version is taken from GB50189 - 2005 "Energy - efficient Design Standard for Public Buildings". The current version GB50189 - 2015 has been updated as follows:

Basic Cycle

IPLV(C) comprehensively reflects the operating efficiency of multi - connected units under partial load. Tested according to a unified method, it can more fairly and reasonably reflect the energy - saving performance of multi - connected unit products! This version is taken from GB50189 - 2005 "Energy - efficient Design Standard for Public Buildings". The current version GB50189 - 2015 has been updated as follows:

Basic Cycle

Related Articles

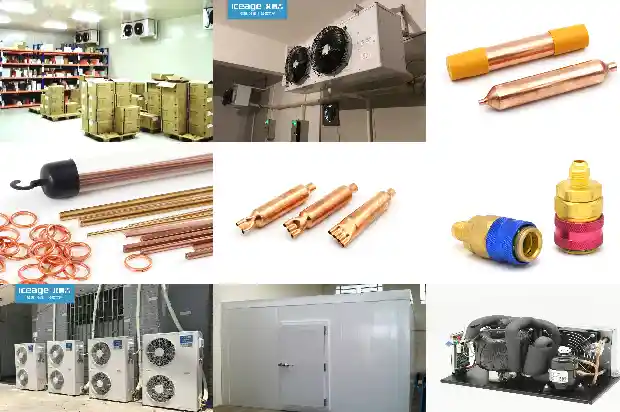

- Introduction to Cold Storage Refrigeration Systems

- Introduction to Energy - saving Methods of Cooling Towers

- Introduction to the Application of End - product, Fan and Motor Characteristics (Fan - coil Unit Section)

- Comprehensive Introduction to Chilled Water Systems of Large - scale Central Air - conditioners

- Introduction to Inspection and Handling Methods for Refrigerant Leak in Cold Storage

- Introduction to Control Valves in Refrigeration Systems

- Introduction to Basic Types of Cold Storage

- Introduction to Lithium Bromide Absorption Chillers

- Introduction to the Advantages of Dual - temperature Cold Storage

- Introduction to Various Water Tanks in Air - conditioning Systems

- Introduction to the Cleaning Processes and Methods of Heat Exchangers and Cooling Towers

- Introduction to Six Kinds of Two-stage Compression Refrigeration Systems

- Introduction to Key Points of Compressor Grouping in Quick-freezing Cold Storage

- Introduction to the Construction and Features of Cold Storage in Cold Chain Logistics

- All-round Introduction to Condensers and Evaporators!

- Introduction to Vapor Barrier of Cold Storage and Moisture Protection of Equipment

- Introduction to Oil Collector in Refrigeration System

- Technical Introduction of Process Cooling Water System