Introduction to the Construction and Features of Cold Storage in Cold Chain Logistics

2024-11-19

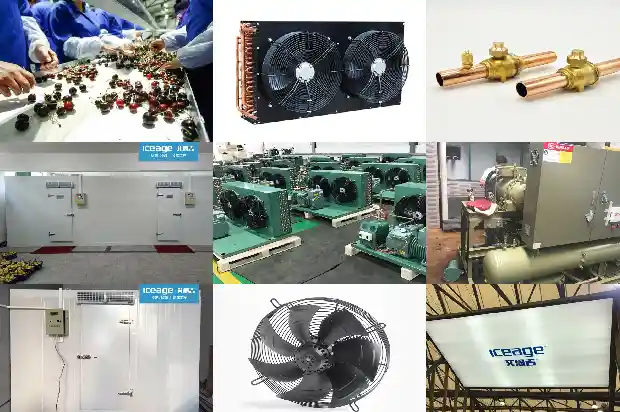

Cold chain logistics cold storage has unique practical significance. It has transformed from the "low-temperature storage" type of traditional cold storage to the "circulation" type and the "cold chain logistics distribution" type. With the ideas of supply chain and systematic management as the core, it comprehensively applies modern information technology, logistics technology, etc., to achieve the cold chain logistics management effect with the optimal input-output ratio, the best operation quality and efficiency, and the lowest operation cost.

The requirements for the site selection and architectural design of cold chain logistics cold storage are strict:

The warehouse cold storage should be built in places with convenient transportation and reliable sources of water and electricity supply. There should be good environmental sanitation conditions around the site, and efforts should be made to avoid locations with harmful gases, smoke, dust from industrial and mining enterprises, and pollution sources from infectious disease hospitals, etc. The logistics cold storage of meat, fish, egg, milk and other processing factories should be arranged on the upwind side with the minimum frequency of summer wind direction in urban residential areas, and located near the production areas or in places convenient for commodity distribution. Generally, the building consists of cold processing and refrigeration buildings, cold processing auxiliary buildings, transportation facilities, management and living quarters buildings, and machine room and ice-making room buildings. The logistics cold storage includes cooling rooms with a temperature of around 0 °C, freezing rooms with a temperature of -23 to -30 °C, refrigerated rooms with a temperature of -12 to -20 °C, and ice storage rooms with a temperature of -4 to -10 °C.

The warehouse cold storage should be built in places with convenient transportation and reliable sources of water and electricity supply. There should be good environmental sanitation conditions around the site, and efforts should be made to avoid locations with harmful gases, smoke, dust from industrial and mining enterprises, and pollution sources from infectious disease hospitals, etc. The logistics cold storage of meat, fish, egg, milk and other processing factories should be arranged on the upwind side with the minimum frequency of summer wind direction in urban residential areas, and located near the production areas or in places convenient for commodity distribution. Generally, the building consists of cold processing and refrigeration buildings, cold processing auxiliary buildings, transportation facilities, management and living quarters buildings, and machine room and ice-making room buildings. The logistics cold storage includes cooling rooms with a temperature of around 0 °C, freezing rooms with a temperature of -23 to -30 °C, refrigerated rooms with a temperature of -12 to -20 °C, and ice storage rooms with a temperature of -4 to -10 °C.

The plane layout of the cold chain logistics cold storage should make the technological process reasonable, with short routes that do not cross each other, clear division of high and low temperature areas, try to minimize the area of the enclosure structure, have a neat column grid distribution, and take expansion and convenience into consideration. Its plane is generally square. Multi-story cold storages are often built in dumbbell-shaped or single-block styles. The dumbbell-shaped style divides the high-temperature cold storage and the low-temperature cold storage into two independent enclosure structures, which are connected by a corridor in the middle and have a good use effect.

Fruits, melons and vegetables that have undergone pre-cooling processing and fresh-keeping refrigeration in the cold chain logistics cold storage can not only be sold across regions, but also have their loss rates reduced from 20% to 5%.

Related Articles

- Introduction to Inspection and Handling Methods for Refrigerant Leak in Cold Storage

- Introduction to Control Valves in Refrigeration Systems

- Introduction to Basic Types of Cold Storage

- Introduction to Lithium Bromide Absorption Chillers

- Introduction to the Advantages of Dual - temperature Cold Storage

- Introduction to Various Water Tanks in Air - conditioning Systems

- Introduction to the Cleaning Processes and Methods of Heat Exchangers and Cooling Towers

- Introduction to Six Kinds of Two-stage Compression Refrigeration Systems

- Introduction to Key Points of Compressor Grouping in Quick-freezing Cold Storage

- All-round Introduction to Condensers and Evaporators!

- Introduction to Vapor Barrier of Cold Storage and Moisture Protection of Equipment

- Introduction to Oil Collector in Refrigeration System

- Technical Introduction of Process Cooling Water System

- Introduction to Air-cooled Chiller

- Introduction to Five Classification Functions of Cold Storage Installation for Refrigeration

- Introduction to Precooling Methods for Fruits and Vegetables

- Introduction to the Relationship between Refrigerants and Cold Storage Temperatures

- Introduction to Types of Condensers in Cold Storage