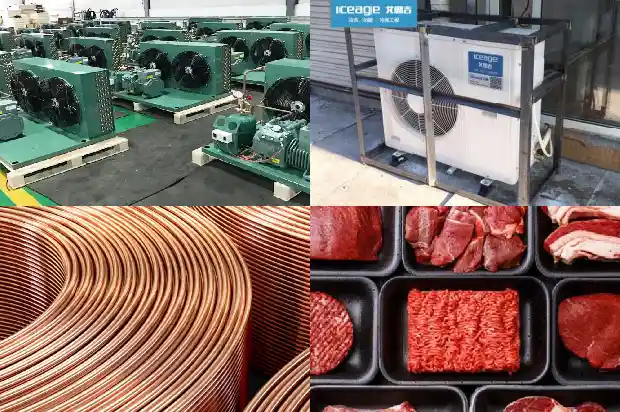

Liquid Supply Methods for Cold Storage Refrigeration Systems

2025-03-14

The cooling methods include direct evaporation cooling and indirect cooling. Currently, the commonly used refrigeration system is the compression refrigeration system. The liquid supply methods of the refrigeration system are direct expansion liquid supply, gravity liquid supply, and refrigerant liquid pump liquid supply. These three liquid supply methods are determined according to the size of the small - scale cold storage and the type of cooling equipment.

I. Direct Expansion Liquid Supply

The refrigerant is directly supplied from the condenser or liquid receiver to the evaporator or cooling coil through the expansion valve. This liquid supply method is called direct expansion liquid supply. This method is relatively simple, but it is difficult to control the appropriate liquid supply volume. The refrigeration effect is reduced due to superheat (insufficient liquid supply) and liquid hammer (excessive liquid supply). For the Freon refrigeration system of a small - scale cold storage, it is suitable to use the superheat control of the expansion valve, and this application is relatively common.

II. Gravity Liquid Supply

This method involves adding a gas - liquid separator between the evaporator and the expansion valve. After storing a certain amount of liquid, the static pressure of the liquid supply column supplies the liquid to the cooling equipment.

When ammonia passes through the expansion valve (manual) or float valve (automatic control) and throttles into the ammonia liquid separator, the flash gas generated by throttling is separated in the separator. The liquid enters the cooling coil through the liquid sub - regulating station. The gas that absorbs heat and evaporates flows into the ammonia liquid separator through the gas sub - regulating station.

If supplying liquid to the top coil of a small - scale cold storage, the ammonia liquid separator should be installed at a position where the liquid level is 1.5m higher than the top coil, and the liquid enters the coil due to the static pressure of the liquid supply column.

When ammonia passes through the expansion valve (manual) or float valve (automatic control) and throttles into the ammonia liquid separator, the flash gas generated by throttling is separated in the separator. The liquid enters the cooling coil through the liquid sub - regulating station. The gas that absorbs heat and evaporates flows into the ammonia liquid separator through the gas sub - regulating station.

If supplying liquid to the top coil of a small - scale cold storage, the ammonia liquid separator should be installed at a position where the liquid level is 1.5m higher than the top coil, and the liquid enters the coil due to the static pressure of the liquid supply column.

III. Refrigerant Liquid Pump Liquid Supply

This method uses a pump to send the low - temperature liquid refrigerant in the low - pressure circulating receiver to the refrigeration equipment for forced liquid supply.

There are two types of ammonia pump liquid supply methods: top - in bottom - out and bottom - in top - out. Each of these two methods has its own advantages and disadvantages. In the bottom - in liquid supply method, the low - temperature ammonia liquid enters the ammonia pump from the low - pressure circulating receiver through a filter. The ammonia pump transports the ammonia liquid to the main regulating station. This regulating station is equipped with multiple pipelines, which respectively supply liquid to the cold storage rooms, freezing rooms, etc. through the liquid sub - regulating stations. At the same time, a bypass pipe is provided, which can return the excess ammonia liquid to the circulating receiver to adjust the liquid supply volume. The return gas in the pipeline enters the low - pressure circulating receiver from the gas separation station. After separating the liquid droplets, it is sucked back by the compressor. The suction pipe is used to discharge the gas in the pump. The discharge pipe is used for draining liquid during hot ammonia defrosting, and the discharged liquid flows to the low - pressure circulating receiver.

There are two types of ammonia pump liquid supply methods: top - in bottom - out and bottom - in top - out. Each of these two methods has its own advantages and disadvantages. In the bottom - in liquid supply method, the low - temperature ammonia liquid enters the ammonia pump from the low - pressure circulating receiver through a filter. The ammonia pump transports the ammonia liquid to the main regulating station. This regulating station is equipped with multiple pipelines, which respectively supply liquid to the cold storage rooms, freezing rooms, etc. through the liquid sub - regulating stations. At the same time, a bypass pipe is provided, which can return the excess ammonia liquid to the circulating receiver to adjust the liquid supply volume. The return gas in the pipeline enters the low - pressure circulating receiver from the gas separation station. After separating the liquid droplets, it is sucked back by the compressor. The suction pipe is used to discharge the gas in the pump. The discharge pipe is used for draining liquid during hot ammonia defrosting, and the discharged liquid flows to the low - pressure circulating receiver.

Related Articles

- Reasons and Hazards of Liquid Hammer in Refrigeration Compressors

- What are the Reasons and Hazards of Uneven Liquid Distribution in the Refrigeration System?

- Four Major Factors Affecting the Boiling Heat Transfer of Refrigerant Liquid

- Analysis of Causes for Compressor Liquid Hammer, Overheating and Pre - heating

- Liquid Level Detection and Control of Flooded Evaporators

- Why Should Refrigerant Be Filled in Liquid Form? What Are the Filling Methods?

- Evaporator Three Ways of Feeding Liquids

- Six Misunderstandings about the Dual-supply Water-based System! Have You Fallen for Them?

- Common Faults and Treatment Methods of Single-phase Asynchronous Motors

- Several Methods of Defrosting in Cold Storage

- Frosting in the Cold Storage? A Detailed Explanation of the 9 Reasons for Frosting of Air Coolers and 4 Defrosting Methods~~

- Why Does the Air Cooler Frost? What Are the Defrosting Methods?

- The Use and Common Maintenance Methods of Refrigeration Compressors

- Wiring Methods, Faults and Classifications of Fan Coil Units, All Here~~

- How Do You Remove Mildew from the Cold Storage? Have You Used These Methods?

- Common Faults in Refrigeration Systems and Handling Methods

- Cleaning Methods of Tubular Coolers

- Oil Cooling Methods and Oil - changing Operation Procedures for Screw Compressors