Maintenance Tips for Cold Storage Compressors

2024-09-08

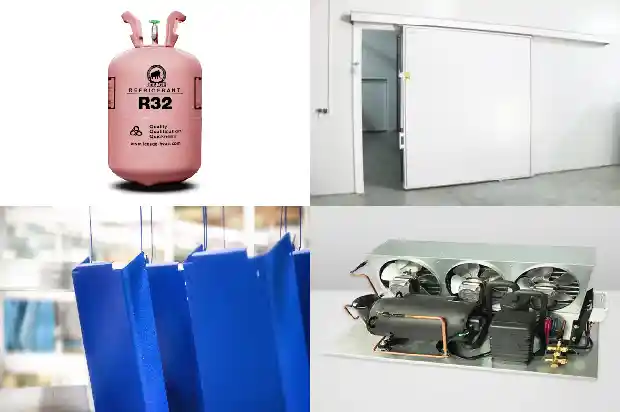

Refrigeration compressors play a core role in cold storage. The process of raising refrigerant vapor from low pressure to high pressure and the continuous flow and transportation of the vapor are all accomplished by the work of the refrigeration compressor. Performing good maintenance on the refrigeration compressor can ensure the normal operation of the cold storage unit in a large sense. The maintenance of the compressor includes the following aspects:

- Voltage phase loss, overload, current protection, delay protection, and electrical components with protection functions must be installed in the refrigeration system. The sensitivity and quality of these components directly affect the lifespan of the compressor.

- The non-condensable gas (air and nitrogen) in the refrigeration system should not exceed 2% in volume. Do not operate the vacuum pump on its own during vacuum pumping. Use a vacuum pump to evacuate from the high-pressure end (discharge valve) of the system for more than 20 minutes.

- Pay attention to the oil level in the compressor's oil sight glass and ensure that the oil level is within the specified range in the oil sight glass. If the compressor is short of oil, it will cause interlocking faults such as seizure, shaft wrapping, and motor burnout.

- Voltage phase loss, overload, current protection, delay protection, and electrical components with protection functions must be installed in the refrigeration system. The sensitivity and quality of these components directly affect the lifespan of the compressor.

- The refrigeration cycle system must be kept dry strictly. Especially when seamless steel pipes are used as evaporators, there should be no rust, and no organic compounds, metal impurities, detergents, acids, or moisture should remain.

- During the installation and commissioning of the refrigeration system, the temperature controller and pressure controller should ensure that the number of starts and stops of the compressor within 1 hour is less than 6 times, each operation lasts for more than 5 minutes, and each stop time is not less than 3 minutes.

- The non-condensable gas (air and nitrogen) in the refrigeration system should not exceed 2% in volume. Do not operate the vacuum pump on its own during vacuum pumping. Use a vacuum pump to evacuate from the high-pressure end (discharge valve) of the system for more than 20 minutes.

- After the refrigeration system is in operation, pay attention to the oil level in a timely manner.

The refrigeration oil should be changed in the first month after putting into operation, and then it should be changed once a year.

- The reliability and sensitivity of electrical control components, temperature, and pressure controllers should be reliable to reduce compressor failures.

- Check whether the power supply voltage and the ambient temperature are within the specified range. Do a good job in maintaining the compressor to ensure the normal operation of the cold storage and the refrigeration effect of the cold storage.

Related Articles

- Basic Faults and Preventive Maintenance of Water - cooled Units

- Essential for Maintenance! Parameters and Phenomena of Normal Operation of Refrigeration and Heating Systems

- Welding Equipment Used in Refrigeration System Maintenance

- Maintenance Methods for Small Modular Cold Storage Failures

- Maintenance Techniques for Air - conditioning Refrigeration Systems

- Maintenance Strategies for the Working Cycle and Electrical Automatic Control of Chillers

- Essential Basics for Maintenance, Debugging of Refrigeration and Air - conditioning Systems

- 8 Maintenance Procedures for Industrial Chillers

- Requirements and Maintenance for Building Meat Food Cold Storage

- Maintenance Methods for Faults in Screw Refrigeration Air - conditioner Compressors

- Maintenance Methods for Refrigerant Leak in Air - conditioner Outdoor Unit

- Knowledge, Installation and Maintenance of Cold Storage Systems

- Are you familiar with the detection and maintenance methods of air conditioner components?

- Maintenance and Operation of Freezing and Cold Storage Warehouses

- Water-cooled Screw Chiller: Operation and Maintenance

- Daily Maintenance Training for Users after Installation of Small and Medium-Sized Cold Storages

- Maintenance of Screw Chiller

- Maintenance of Screw Chiller