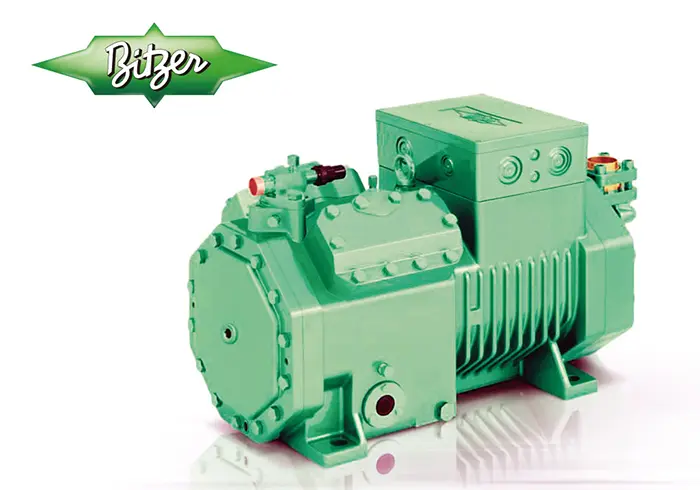

Oil Cooling Methods and Oil Leakage Operations for Screw Compressors

The lubricating oil separated from the high-temperature and high-pressure oil-gas mixture discharged from the compressor has a relatively high temperature and cannot be directly injected into the compressor. It needs to be cooled by the oil cooler to reach the viscosity and temperature required by the compressor before it can be reused. The oil cooling methods can adopt four ways: water cooling, thermosiphon, liquid injection cooling, and enlarged oil cooler.

Screw Compressor Oil Cooling Methods

(1) Water-cooled Oil Cooler

The water-cooled oil cooler is a horizontal shell-and-tube heat exchanger with oil outside the tubes and water inside the tubes. The tube bundles are fixed on the tube plates at both ends. There are baffles in the cylinder of the oil cooler, which can improve the heat exchange between oil and cooling water. The inlet temperature of the cooling water for the oil cooler should be less than 32°C, and the oil temperature of the unit is controlled at 40 - 65°C.

(2) Thermosiphon Oil Cooler

The structure of the thermosiphon oil cooler is similar to the principle of the water-cooled oil cooler. It is a horizontal shell-and-tube type with oil outside the tubes and refrigerant inside the tubes. The oil temperature after being cooled by the thermosiphon oil cooler is generally 10 - 20°C higher than the condensation temperature.

(3) Liquid Injection Cooling

In the unit with liquid injection cooling, the high-pressure refrigerant liquid led out from the condenser or receiver passes through the filter, throttle valve or high-temperature expansion valve and is injected into a certain intermediate orifice of the compressor to absorb the compression heat and cool the oil temperature.

(4) Air Cooling

The air cooling system is an indirect cooling method. It cools the oil in the oil cooler through the ambient atmosphere.

Reasons and Operations for Oil Leakage of Screw Compressor

The so-called oil leakage is manifested as no trace of oil can be seen in the oil separator, and all the oil comes to the condenser along with the exhaust gas. If the water temperature continues to be low, all the oil will accumulate in the condenser and cause the expansion valve to be blocked by oil. Due to insufficient liquid supply in the evaporator, the pressure begins to decrease until the low-pressure alarm stops the unit. The main reason for oil leakage is that the temperature of the chilled water is low and the exhaust temperature is low.

When it is found that the oil level in the oil separator is decreasing, immediately switch the unit to the manual control mode and limit the compressor load, for example, limit its energy to 50% to increase the condensing pressure. Reduce the low-pressure alarm value and low-pressure shutdown value of the unit to the allowable range to ensure that the unit can operate as much as possible.

If at this time the oil level is still very low and the pressure in the evaporator is also very low, it is necessary to consider whether the oil has all run into the evaporator. Check from the sight glass of the evaporator to see if there are a large number of white foams rolling. If there are, it indicates that the oil is all in the evaporator; otherwise, it may be in the condenser. With the above several steps, after about half an hour, the temperature of the cooling water and the exhaust temperature should increase to normal, and then start to collect the oil.

If the oil is in the evaporator, pay close attention to the temperature of the chilled water at this time. First, appropriately reduce its flow rate to lower the outlet water temperature, and then quickly increase the flow rate to rapidly increase the outlet water temperature of the evaporator. At this time, the water temperature will exceed the saturation temperature of the refrigerant by a lot, causing the refrigerant to boil vigorously. The refrigeration oil will be sucked into the compressor along with the rolling refrigerant foam. At this time, the exhaust temperature should decrease somewhat, but it should also be far above the separation temperature of the oil and the refrigerant, thus bringing the oil back to the oil separator and separating them. Repeat this several times, and all the oil will be collected back into the oil separator. Note the time interval for each adjustment of the water volume. It is best that the exhaust temperature returns to the best before adjustment after each adjustment.

If the oil is in the condenser, there is no need to pay too much attention to the water temperature at this time. As long as the unit can operate normally, there will not be a big problem. At this time, the expansion valve should be gradually opened to the maximum (the opening process should not be too fast to prevent excessive liquid supply from damaging the copper tubes in the evaporator). Wait for a few minutes until the high and low pressures of the unit are balanced. At this time, a large number of white foams can be seen from the sight glass of the evaporator, indicating that the oil has entered the evaporator from the condenser. Just repeat the above steps, and the oil will be collected back quickly.

- Has Your Refrigeration System Experienced "Oil Carry - over"?

- Causes and Prevention of "Primary Condensation" and "Secondary Condensation" in Fan - Coil Units

- Common Faults of HVAC Fan Coil Units

- Introduction to Oil Collector in Refrigeration System

- Forms of Oil Separators

- How to troubleshoot dirty blockage, ice blockage and oil blockage in refrigeration systems?

- Installation and Oil Return Precautions for Refrigeration Equipment Pipelines

- Precautions for Replacing Refrigeration Compressor Refrigerant Oil

- What are the reasons for the poor oil return of screw compressors?

- Freezing Chamber System Blockage, Dirty Blockage, and Oil Blockage Characteristics and Treatment Methods

- Precautions for Commissioning of Screw Parallel Units

- Composition and Common Faults of Screw Refrigeration Compressors

- Operation of Screw - type Water - cooled Chiller Units

- What Are the Reasons for Insufficient Air Output of Screw Air Compressors?

- How to Schedule Overhauls, Medium - sized and Minor Repairs of Screw Refrigeration Compressors?

- Maintenance Methods for Faults in Screw Refrigeration Air - conditioner Compressors

- Reference Points for Selection of Screw - type Chillers

- Water-cooled Screw Chiller: Operation and Maintenance