Prefabricated Controlled Atmosphere Warehouse - Prolonging the Fresh - keeping Period of Fruits and Vegetables

2025-02-25

Prefabricated controlled - atmosphere warehouses are a type of modular cold storage. Their panels are also assembled using insulated sandwich panels, and they can be classified into high - temperature (8 - 15°C), medium - temperature (0 - 8°C), and low - temperature (-2 - 0°C) types.

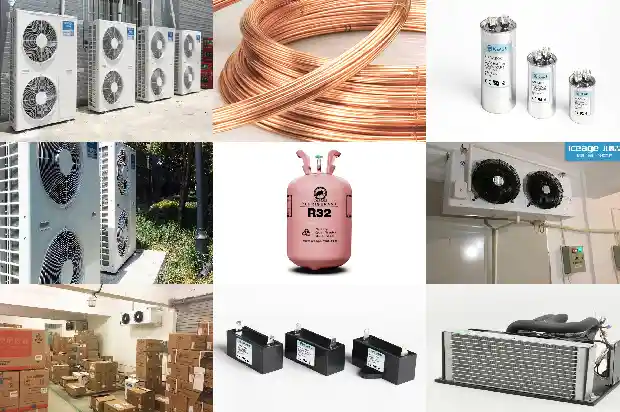

A prefabricated controlled - atmosphere warehouse consists of a warehouse body, refrigeration equipment, controlled - atmosphere equipment, a gas analyzer, and auxiliary accessories. The controlled - atmosphere equipment includes an oxygen remover, a carbon - dioxide remover, an ethylene remover, a nitrogen generator, a humidifying device, etc., and is equipped with an automatic control system including instruments for temperature and humidity control, a gas analyzer, etc.

For the warehouse body of a prefabricated controlled - atmosphere warehouse, in addition to meeting the requirements of the modular cold - storage body, stricter airtightness requirements are imposed. The airtightness test of a controlled - atmosphere warehouse is generally carried out as follows: after the pressure in the empty warehouse reaches 100 Pa (gauge pressure), maintain the pressure for 10 minutes, and the remaining pressure in the warehouse should not be lower than 50 Pa (gauge pressure).

Due to the strict airtightness requirements in the warehouse, to prevent the warehouse body from deforming caused by excessive pressure difference between the inside and outside of the warehouse, the controlled - atmosphere warehouse is also equipped with pressure - balance components, such as a pressure - balance safety valve and a buffer gas - storage bag.

Similarly, to ensure airtightness, the controlled - atmosphere warehouse uses a controlled - atmosphere door with good heat - preservation and airtight properties. During the long - term storage process after the controlled - atmosphere warehouse is sealed, it is generally not allowed to open the controlled - atmosphere door casually, so as to avoid gas exchange between the inside and outside of the warehouse and cause fluctuations in the gas composition in the warehouse. Therefore, in order to facilitate understanding the storage situation of fruits and vegetables in the warehouse, an observation window is set in the controlled - atmosphere warehouse to inspect the stored goods through the window.

Precautions for the Installation of Prefabricated Controlled - Atmosphere Warehouses

- The performance parameters and quality of the controlled - atmosphere equipment used in the controlled - atmosphere warehouse should comply with the relevant standard provisions.

- The controlled - atmosphere equipment, pipelines, and control valves should be arranged neatly and installed firmly. The connection of system pipelines should meet the requirements of product drawings and technical documents.

- The length of the controlled - atmosphere pipeline should not exceed 100 m; the deflection of each pipeline should not be greater than 1/350; there should be no drooping U - shaped elbows in the pipeline; the pipeline should slope towards the inside of the controlled - atmosphere warehouse, and a flexible hose should be used to connect it with the controlled - atmosphere machine.

- The controlled - atmosphere equipment should have good airtightness. Equipment using combustion for oxygen reduction should be equipped with a water - cut - off alarm device.

The fuel gas (material) should be placed outside the controlled - atmosphere equipment room and should comply with relevant fire - safety regulations.

- The controlled - atmosphere equipment room should be equipped with a mechanical ventilation device and be isolated from the refrigeration equipment room.

- The gas - analysis instrument should be sensitive and accurate, and the accuracy should not be lower than 0.1%.

- The time required to adjust the air in the empty controlled - atmosphere warehouse to an oxygen content of 3% ± 0.5% and a carbon - dioxide content of 5% ± 0.5% (abbreviated as "controlled - atmosphere time"): for a single - room storage capacity of less than 1000 m³, the controlled - atmosphere time is less than 96 h; for a single - room storage capacity of 1000 m³ or more, the controlled - atmosphere time is less than 120 h.

During the acceptance after installation, in addition to conducting the acceptance according to the content of the modular cold - storage acceptance, the acceptance of the controlled - atmosphere warehouse should focus on the airtightness test of the warehouse body and the controlled - atmosphere test (controlled - atmosphere time) of the empty warehouse.

When using the controlled - atmosphere warehouse, the goods should be moved in and out quickly. During the storage process, the number of door openings should be minimized as much as possible. Try to store goods to fill the warehouse to shorten the controlled - atmosphere time and reduce the operating cost.

Related Articles

- What are the Storage Conditions of Nectarine in Controlled Atmosphere Cold Storage?

- Conditions for Storage of Persimmons in Controlled Atmosphere Cold Storage

- Reasons for Higher Cost of Controlled Atmosphere Cold Storage than Ordinary Cold Storage

- Maintenance and Operation of Freezing and Cold Storage Warehouses

- Introduction to Precooling Methods for Fruits and Vegetables