Principle and Refrigeration Process of Piston Refrigeration Compressor

2024-09-14

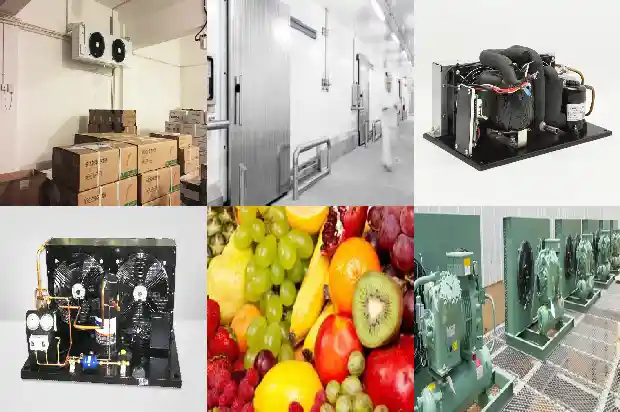

Piston refrigeration compressors have mature technology, high efficiency, a wide range of operating temperatures, and are suitable for multiple refrigerants. They are widely used in large and medium-sized cold storage as a refrigeration model.

I. Working principle of piston compressors

When the crankshaft of a piston compressor rotates, through the transmission of the connecting rod, the piston makes reciprocating motion. The working volume formed by the inner wall of the cylinder, the cylinder head, and the top surface of the piston will change periodically. When the piston of the piston compressor starts to move from the cylinder head, the working volume in the cylinder gradually increases. At this time, the gas enters the cylinder by pushing open the intake valve along the intake pipe until the working volume reaches its maximum, and then the intake valve closes. When the piston of the piston compressor moves in the opposite direction, the working volume in the cylinder shrinks and the gas pressure rises. When the pressure in the cylinder reaches and is slightly higher than the exhaust pressure, the exhaust valve opens and the gas is discharged from the cylinder until the piston moves to the limit position, and then the exhaust valve closes. When the piston of the piston compressor moves in the opposite direction again, the above process repeats. In short, when the crankshaft of the piston compressor rotates one week, the piston reciprocates once, and the processes of intake, compression, and exhaust are successively realized in the cylinder, completing a working cycle.

When the crankshaft of a piston compressor rotates, through the transmission of the connecting rod, the piston makes reciprocating motion. The working volume formed by the inner wall of the cylinder, the cylinder head, and the top surface of the piston will change periodically. When the piston of the piston compressor starts to move from the cylinder head, the working volume in the cylinder gradually increases. At this time, the gas enters the cylinder by pushing open the intake valve along the intake pipe until the working volume reaches its maximum, and then the intake valve closes. When the piston of the piston compressor moves in the opposite direction, the working volume in the cylinder shrinks and the gas pressure rises. When the pressure in the cylinder reaches and is slightly higher than the exhaust pressure, the exhaust valve opens and the gas is discharged from the cylinder until the piston moves to the limit position, and then the exhaust valve closes. When the piston of the piston compressor moves in the opposite direction again, the above process repeats. In short, when the crankshaft of the piston compressor rotates one week, the piston reciprocates once, and the processes of intake, compression, and exhaust are successively realized in the cylinder, completing a working cycle.

II. Refrigeration process of piston compressors

The refrigeration process is carried out in a closed circulation system composed of ammonia compressors, coolers, regulating valves, evaporators, etc. After the ammonia liquid enters the evaporator through the regulating valve and the pressure is reduced, it absorbs the heat of the cooled medium and evaporates, reducing the temperature of the medium and achieving the purpose of refrigeration. The evaporated ammonia gas is sucked back by the compressor and discharged into the cooler after compression. The ammonia gas is cooled and condensed into ammonia liquid.

The refrigeration process is carried out in a closed circulation system composed of ammonia compressors, coolers, regulating valves, evaporators, etc. After the ammonia liquid enters the evaporator through the regulating valve and the pressure is reduced, it absorbs the heat of the cooled medium and evaporates, reducing the temperature of the medium and achieving the purpose of refrigeration. The evaporated ammonia gas is sucked back by the compressor and discharged into the cooler after compression. The ammonia gas is cooled and condensed into ammonia liquid.

III. Advantages of piston compressors

- Piston compressors have a wide range of applicable pressure ranges. Regardless of the flow rate, the required pressure can be reached.

- Piston compressors have high thermal efficiency and low power consumption per unit.

- Strong adaptability, that is, a wide range of exhaust gas, and not affected by high or low pressure, can adapt to a wide range of pressure ranges and refrigeration capacity requirements.

- Piston compressors have low requirements for materials, mostly using ordinary steel materials, which are easier to process and have a lower cost.

- Piston compressors are relatively mature in technology and have accumulated rich experience in production and use.

- The device system of piston compressors is relatively simple.

IV. Disadvantages of piston compressors

- The rotational speed is not high, and the machine is large and heavy.

- The structure is complex, there are many wearing parts, and the maintenance volume is large.

- The exhaust is not continuous, causing air flow pulsation.

- There is a relatively large vibration during operation.

V. Classification of piston refrigeration compressors

(1) Classified by sealing method, it can be divided into three types: open type, semi-hermetic type, and fully hermetic type.

The crankshaft power input end of an open-type compressor extends out of the body and is connected to the motor through a transmission device. The heat generated during compression will not be transmitted to the motor, which is beneficial for preventing the motor from overheating in large compressors. The refrigerant also does not contact the motor coil, which is suitable for ammonia that has a corrosive effect on copper. Therefore, ammonia refrigeration compressors in large and medium-sized food freeze-drying machines are all open-type. The disadvantage of open-type compressors is that the refrigerant may leak through the shaft of the compressor extending out of the casing.

The semi-hermetic compressor connects the compressor and the matched motor with detachable bolts in the same body and shares a main shaft. No shaft seal device is needed, reducing the possibility of leakage. The low-temperature refrigerant vapor inhaled by this model often passes through the motor first, which can reduce the temperature rise of the motor, which is beneficial to improving the service life of the machine. In addition, the noise is lower. Most medical freeze-drying machines for production use this model.

The fully hermetic compressor welds the motor and the compressor in the same casing. Different from the semi-hermetic compressor, after welding, it can only be disassembled by cutting, so maintenance is inconvenient.

It is suitable for small refrigerators with small refrigeration capacity.

(2) Classified by stages, there are single-stage compressors and single-machine double-stage compressors. Centrifugal compressors also have multi-stage compressors.

(3) Classified by the refrigerants compressed, there are ammonia refrigeration compressors, fluorine refrigeration compressors, and other refrigerant compressors.

(1) Classified by sealing method, it can be divided into three types: open type, semi-hermetic type, and fully hermetic type.

The crankshaft power input end of an open-type compressor extends out of the body and is connected to the motor through a transmission device. The heat generated during compression will not be transmitted to the motor, which is beneficial for preventing the motor from overheating in large compressors. The refrigerant also does not contact the motor coil, which is suitable for ammonia that has a corrosive effect on copper. Therefore, ammonia refrigeration compressors in large and medium-sized food freeze-drying machines are all open-type. The disadvantage of open-type compressors is that the refrigerant may leak through the shaft of the compressor extending out of the casing.

The semi-hermetic compressor connects the compressor and the matched motor with detachable bolts in the same body and shares a main shaft. No shaft seal device is needed, reducing the possibility of leakage. The low-temperature refrigerant vapor inhaled by this model often passes through the motor first, which can reduce the temperature rise of the motor, which is beneficial to improving the service life of the machine. In addition, the noise is lower. Most medical freeze-drying machines for production use this model.

The fully hermetic compressor welds the motor and the compressor in the same casing. Different from the semi-hermetic compressor, after welding, it can only be disassembled by cutting, so maintenance is inconvenient.

It is suitable for small refrigerators with small refrigeration capacity.

(2) Classified by stages, there are single-stage compressors and single-machine double-stage compressors. Centrifugal compressors also have multi-stage compressors.

(3) Classified by the refrigerants compressed, there are ammonia refrigeration compressors, fluorine refrigeration compressors, and other refrigerant compressors.

Related Articles

- Principles, Components and Heat Recovery of Modular Units

- What are Refrigeration Equipment? What's the Principle of Chillers?

- What Is the Working Principle of Refrigeration Equipment?

- Operating Principle and Standard Installation Steps of Multi - split Systems in Refrigerant Air - conditioning Systems

- Working Principle of AC Inverter and DC Inverter Air Conditioners

- What's the principle and function of air energy?

- Principles of Refrigeration Systems and Functions of Components Explained

- Working Principle and Control Logic of Centrifugal Compressor

- Function and Working Principle of Subcooler

- Fault Analysis of Working Principle of Screw Chiller Unit

- Working Principle of Economizer for Refrigeration Compressor

- Principle of Multiple Storages in One Unit and Evaporation Pressure Regulation Methods

- Characteristics and principles of air-cooled and water-cooled units

- Air-source heat pump: Principle of cooling and heating in one machine

- Industrial screw water chiller working principle

- Water Cooled Unit Principle of Operation and Parameter Failure Analysis

- The principle of air conditioning refrigeration

- Have You Encountered the Three Common Problems of Refrigeration Compressors?