Principles, Components and Heat Recovery of Modular Units

2025-02-14

I. Main Characteristics and Principles of Air - Cooled Modular Units

The air - cooled modular unit is a central air - conditioning unit that uses air as the cooling (heating) source and water as the cooling (heating) medium. That is, the condenser is a fin - type heat exchanger, and the evaporator is a heat exchanger for water - fluorine heat exchange applications, such as coaxial, shell - and - tube, and plate heat exchangers.

As an integrated device for both cooling and heating, the air - cooled heat pump eliminates various auxiliary components like cooling towers, cooling water pumps, boilers, and related pipeline systems. The system has a simple structure, saves installation space, is easy to maintain and manage, and is energy - efficient. It is particularly suitable for areas with water shortages.

- Cooling Mode: The high - temperature refrigerant gas discharged from the compressor condenses into a liquid in the air - side heat exchanger. After being throttled and depressurized by the throttling device, it enters the water - side heat exchanger. It evaporates after absorbing heat and then returns to the compressor, completing a refrigeration cycle. Meanwhile, the air - conditioning water from indoors is cooled as it passes through the water - side heat exchanger.

- Heating Mode: The high - temperature refrigerant gas discharged from the compressor condenses into a liquid in the water - side heat exchanger. After being throttled and depressurized by the throttling device, it enters the air - side heat exchanger. It evaporates after absorbing heat and then returns to the compressor, completing a heating cycle. At the same time, the air - conditioning water from indoors is heated as it passes through the water - side heat exchanger.

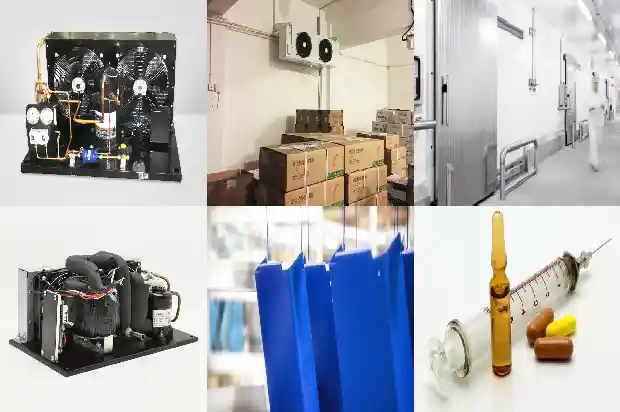

II. Main Components of Air - Cooled Modular Units

- Scroll Compressor: It features small size, light weight, high efficiency, low vibration and noise, reliable operation, and high machining accuracy requirements.

- Coaxial Heat Exchanger: It is formed by coiling and processing two concentric tubes. Its unique and compact structure prevents thermal fatigue, increases heat transfer efficiency, and reduces the external dimensions.

It is especially suitable for high - temperature, high - pressure, and low - flow - rate applications. Main features: There is no cross - contamination between the fluids in the tube - side and shell - side, and it has a large heat - transfer area in a small volume.

- Air - Cooled Fin Heat Exchanger: High - quality copper tubes and enhanced aluminum fins made of hydrophilic membrane materials are joined by a tube - expanding machine. The tube - fin connection is tight, ensuring high heat - transfer efficiency. It is also convenient for operation, maintenance, and cleaning.

- Four - Way Reversing Valve: It is a special solenoid valve with two inlets and two outlets, used to switch between the heating and cooling modes in a compression - type heat pump system. When the heat pump switches from the cooling mode to the heating mode, the four - way reversing valve activates (moving to the heating - mode position). As a result, the indoor evaporator functions as a condenser, and the high - temperature refrigerant vapor discharged from the compressor flows into the indoor evaporator (now acting as a condenser) through the four - way valve, while the condenser becomes an evaporator, completing the mode conversion.

- Thermal Expansion Valve: It is a control mechanism that regulates the flow rate of the volatile refrigerant entering the evaporator.

It throttles and depressurizes, controls the flow rate, and controls the superheat.

- Electronic Expansion Valve: It adjusts the liquid supply to the evaporator according to a preset program. Since it operates in an electronic adjustment mode, it is called an electronic expansion valve.

- Thermal Expansion Valve: The pressure change of the temperature - sensing medium inside its temperature - sensing bulb significantly affects and adjusts the opening degree of the expansion valve.

- Solenoid Valve: It automatically connects and disconnects the pipeline of the refrigeration system. It controls the valve's opening and closing through the electromagnetic force generated when an electric current passes through the electromagnet, preventing liquid hammer.

- Drier - Filter: It filters moisture and impurities, keeping the refrigeration system dry and clean. It is typically installed before the throttling element.

- Liquid Equalizer: It evenly distributes the refrigerant.

- Plate Heat Exchanger: It can effectively improve the unit's heat - exchange efficiency and enhance the IPLV (Integrated Part - Load Value) of the unit under partial load.

- Controller: It has functions such as safety protection and remote control.

III. Total Heat Recovery and Partial Heat Recovery

Partial heat recovery uses a series - connection form; total heat recovery uses a system - switching form.

- Total Heat Recovery of Air - Cooled Heat Pump - Cooling: At this time, it operates like an ordinary air - cooled chiller, providing chilled water for air - conditioning. The refrigerant directly flows into the air - cooled condenser for condensation.

- Total Heat Recovery of Air - Cooled Heat Pump - Cooling and Heat Recovery: The high - temperature and high - pressure refrigerant flows directly from the compressor to the heat recovery device. The unit provides 7°C chilled water while also supplying 55°C domestic hot water. The COP (Coefficient of Performance) is extremely high, making it highly energy - efficient.

- Total Heat Recovery of Air - Cooled Heat Pump - Air - Conditioning Heating: At this time, it operates like an ordinary air - cooled heat pump unit, providing hot water for air - conditioning. The refrigerant directly flows into the water - side heat exchanger to absorb heat from the air.

- Total Heat Recovery of Air - Cooled Heat Pump - Heat Pump Water Heater: The refrigerant of the unit flows directly from the compressor into the heat recovery device. It can provide 55°C domestic hot water, and the unit absorbs heat from the air.

Related Articles

- Principles of Refrigeration Systems and Functions of Components Explained

- Characteristics and principles of air-cooled and water-cooled units

- Basic Knowledge of Valve - type Components in Refrigeration Systems (Technical Sharing)

- Analysis of 6 Components in Air - cooled Multi - split Systems

- Analysis of Advantages, Disadvantages and 34 Common Components of Multi - split Air Conditioners

- Are you familiar with the detection and maintenance methods of air conditioner components?

- Top Ten Components of Refrigeration Systems and Five Common Troubleshooting!

- Refrigeration System Circulation and Components for Freezing and Cold Storage

- Defrosting Operation Modes of Refrigeration Equipment and Its Control Components

- Refrigeration System Components and Common Failures

- Structural Components of Centrifugal Compressor

- The Structure and Components of Centrifugal Compressors

- Introduction to the Components of a Cold Storage Unit and Common Issues in Cold Storage Units

- Water-cooled Split Air Conditioner Unit: Components and Installation

- Essential for Maintenance! Parameters and Phenomena of Normal Operation of Refrigeration and Heating Systems

- Considerations in Selecting Packaged Air Conditioners and Their Heat Recovery Operations

- Frosting and Defrosting Issues of Air - cooled Heat Pumps

- 9 Heating and Cooling Solutions: Pros and Cons You Must Know!