Requirements and Maintenance for Building Meat Food Cold Storage

2024-12-30

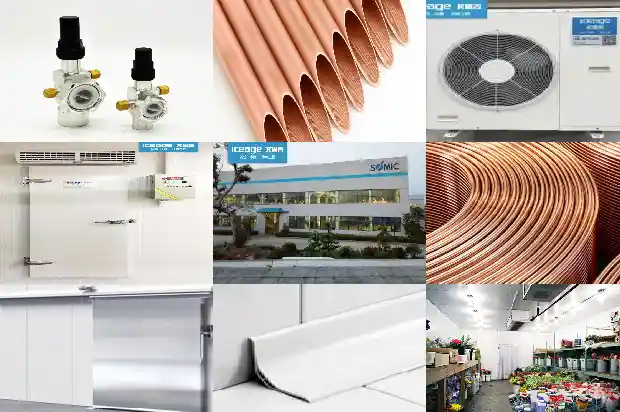

The construction methods and cold storage equipment used for all cold storages are more or less similar, but the specific requirements for different types of cold storages vary. For example, the required temperatures, the thickness of the insulation panels, and the horsepower of the refrigeration units for fruit fresh-keeping cold storages and frozen meat food cold storages are all different.

Requirements for the Construction of Meat Food Cold Storages

- First, when choosing a refrigeration system, select a microcomputer fully automatic digital display electrical controller with automatic temperature control. The meat cold storage does not require manual operation, which is convenient for use and management.

- The cold storage equipment should be energy - saving, power - saving, and low - noise refrigeration equipment. For meat food cold storages, imported or domestic refrigeration compressors are selected, which have low energy consumption and low noise.

- For the cold storage body of meat food cold storages, choose cold storage panels made of color - coated steel plates or stainless - steel plates. These panels are non - toxic, odorless, non - rusting, and can reduce the cold transfer caused by the temperature difference between indoor and outdoor, so as to achieve the maximum efficiency of the freezing and refrigeration system.

- The insulation effect of the cold storage must be good. The meat food cold storage should use advanced composite materials as insulation materials to make composite panel walls. These walls are lightweight, high - strength, have good heat insulation, are corrosion - resistant, anti - aging, moth - proof, non - toxic, and non - mildewing. Especially at ultra - low temperatures, their superiority can be more prominently displayed.

Precautions for the Maintenance of Meat Food Cold Storages:

- Maintenance of the cold storage floor: Generally, the floors of small prefabricated cold storages use insulation boards. When using the cold storage, prevent a large amount of ice and water from accumulating on the floor. If there is ice, do not use hard objects to knock when cleaning to avoid damaging the floor.

- Maintenance of the cold storage panels: Pay attention to prevent hard objects from colliding with and scratching the cold storage body during use to avoid reducing the local insulation performance of the cold storage body.

- Maintenance of the joints of the cold storage: There are certain gaps between the cold storage panels. These gaps are sealed with sealant during construction to prevent air and moisture from entering. Therefore, in use, repair the parts where the sealing has failed in a timely manner.

- When the cold storage is installed or used again after a long - term shutdown, the cooling speed should be reasonable. It is advisable to control it at 8 - 10℃ per day, and it should be maintained at 0℃ for a certain period of time.

Related Articles

- What Vacuum Requirements Do Cold Storage Equipment Have?

- What Special Requirements are There for the Installation of Tea Cold Storage?

- Requirements of Cold Storage Insulation for Maintaining Stable Temperature Inside

- Temperature Requirements for Various Cold Storages

- Return Bend Setup and Installation Technical Requirements

- Types and Temperature Requirements of Seed Cold Storages

- Differences, Requirements and Standards between Pharmaceutical Cold Storage and Conventional Cold Storage

- Technical quality requirements for refrigerators after repair

- System Airtightness Experiment Requirements and Steps

- Basic Faults and Preventive Maintenance of Water - cooled Units

- Essential for Maintenance! Parameters and Phenomena of Normal Operation of Refrigeration and Heating Systems

- Welding Equipment Used in Refrigeration System Maintenance

- Maintenance Methods for Small Modular Cold Storage Failures

- Maintenance Techniques for Air - conditioning Refrigeration Systems

- Maintenance Strategies for the Working Cycle and Electrical Automatic Control of Chillers

- Essential Basics for Maintenance, Debugging of Refrigeration and Air - conditioning Systems

- 8 Maintenance Procedures for Industrial Chillers

- Maintenance Methods for Faults in Screw Refrigeration Air - conditioner Compressors