Sensor for Refrigerant Leak Detection in Cold Chain Transportation

2025-01-04

R - 134a Refrigerant (Tetrafluoroethane)

R - 134a refrigerant, also known as R134a, HFC134a, HFC - 134a, tetrafluoroethane, has commercial names such as SUVA 134a, Genetron 134a, KLEA 134a, etc. Its Chinese name is tetrafluoroethane, and its English name is 1,1,1,2 - tetrafluoroethane.

R - 134a refrigerant, also known as R134a, HFC134a, HFC - 134a, tetrafluoroethane, has commercial names such as SUVA 134a, Genetron 134a, KLEA 134a, etc. Its Chinese name is tetrafluoroethane, and its English name is 1,1,1,2 - tetrafluoroethane.

Main Uses of R - 134a

As the most widely used medium - and low - temperature environmentally friendly refrigerant, due to the good comprehensive performance of HFC - 134a, it has become a very effective and safe substitute for CFC - 12. It is mainly applied in most fields where R - 12 (R12, Freon 12, F - 12, CFC - 12, Freon 12, dichlorodifluoromethane) refrigerant is used, including refrigerators, freezers, water dispensers, automotive air conditioners, central air conditioners, dehumidifiers, cold storage, commercial refrigeration, ice water machines, ice - cream machines, refrigeration and condensing units, etc. At the same time, it can also be used in aerosol propellants, medical aerosols, insecticide propellants, polymer (plastic) physical blowing agents, and protective gases for magnesium alloys.

Although R134a refrigerant is the most common choice to replace Freon R12 in newly installed refrigeration equipment, because the physical and chemical properties, theoretical cycle performance, and compressor oil of R134a and R12 are different, for the after - sales maintenance of refrigeration equipment initially installed with R12 refrigerant, if refrigerant needs to be re - filled or replaced, only R12 can be added. Usually, R134a cannot directly replace R12 (that is, a replacement like "changing blood" is generally not allowed).

As the most widely used medium - and low - temperature environmentally friendly refrigerant, due to the good comprehensive performance of HFC - 134a, it has become a very effective and safe substitute for CFC - 12. It is mainly applied in most fields where R - 12 (R12, Freon 12, F - 12, CFC - 12, Freon 12, dichlorodifluoromethane) refrigerant is used, including refrigerators, freezers, water dispensers, automotive air conditioners, central air conditioners, dehumidifiers, cold storage, commercial refrigeration, ice water machines, ice - cream machines, refrigeration and condensing units, etc. At the same time, it can also be used in aerosol propellants, medical aerosols, insecticide propellants, polymer (plastic) physical blowing agents, and protective gases for magnesium alloys.

Although R134a refrigerant is the most common choice to replace Freon R12 in newly installed refrigeration equipment, because the physical and chemical properties, theoretical cycle performance, and compressor oil of R134a and R12 are different, for the after - sales maintenance of refrigeration equipment initially installed with R12 refrigerant, if refrigerant needs to be re - filled or replaced, only R12 can be added. Usually, R134a cannot directly replace R12 (that is, a replacement like "changing blood" is generally not allowed).

Refrigerated Transportation: Medium - and Long - distance Transportation and Short - distance Distribution of Food and Other Logistics Links

The refrigerated transportation link is the one we are most familiar with. Refrigerated transportation includes medium - and long - distance transportation and short - distance distribution of food and other logistics links. Refrigeration mainly involves several means of transportation such as railway refrigerated cars, road refrigerated vehicles, refrigerated ships, and refrigerated containers. Among them, road vehicles are the main force of refrigerated transportation in China at present.

During the refrigerated transportation process, temperature fluctuations are one of the main reasons for the decline in food quality. Therefore, the transportation tools should have good performance. While maintaining the specified low temperature, they should also maintain a stable temperature, which is particularly important for long - distance transportation.

The frozen sales link is the one that people usually come into contact with the most in daily life. Frozen sales include the frozen storage and sales of various cold - chain foods in the wholesale and retail links, which are jointly completed by manufacturers, wholesalers, and retailers.

With the rapid development of various chain supermarkets in cities, various chain supermarkets are becoming the main sales channels for cold - chain foods. In these retail terminals, a large number of refrigerated/freezer display cabinets and storage warehouses are used, gradually becoming an indispensable and important part of the complete food cold chain.

There are Three Types of Cold - chain Transportation: Fresh - keeping, Chilled, and Frozen

For the entire cold - chain logistics, people in the special - purpose vehicle industry are most concerned about the cold - chain transportation link. At present, refrigerated transportation in China is mainly carried out by road.

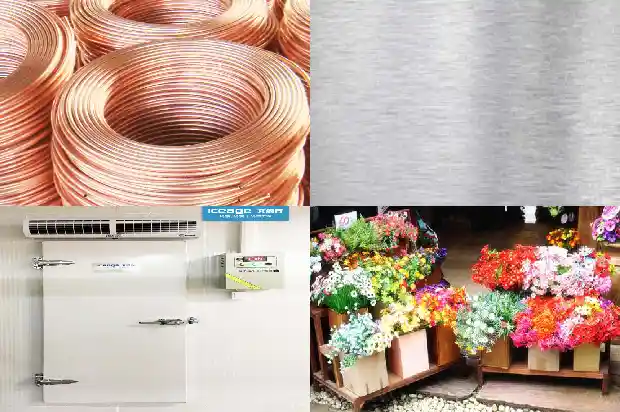

Cold - chain transportation can be divided into two categories according to the degree of food processing: primary agricultural products and processed foods. Primary agricultural products include vegetables, fruits, meat, poultry, eggs, milk, aquatic products, and flower products. Processed foods include frozen foods, packaged cooked foods such as poultry, meat, and aquatic products, ice - cream and dairy products, and fast - food ingredients.

Different foods have different temperature requirements for freshness - keeping, so the types of vehicles required for transportation are also different. According to the different temperatures required for food transportation, cold - chain transportation can be further divided into three types: fresh - keeping, chilled, and frozen.

Fresh - keeping goods include vegetables, flowers, fruits, fresh - keeping vaccines, and live aquatic products, and the required transportation temperature is around 2 - 8 degrees Celsius. Chilled goods mainly include acid - removed meat products, river and sea aquatic products, soy products, vaccine products, chocolate, etc., and the required transportation temperature is between 0 and 5 degrees Celsius. Frozen goods include frozen foods, frozen river and sea aquatic products, frozen meat, and frozen meat products, etc., and the required transportation temperature is between - 10 and - 18 degrees Celsius.

However, during the cold - chain transportation process, due to road bumps, it is easy to cause the joints of refrigeration equipment to loosen or even rupture, resulting in refrigerant leakage. Refrigerant leakage will affect the refrigeration effect and thus cannot guarantee the freshness - keeping quality. If the amount of refrigerant leakage is large, it is also easy to cause an explosion when encountering an open flame. Therefore, it is necessary to regularly check the points prone to leakage.

It is recommended to use a portable refrigerant leak detector to detect refrigerant leakage. It is easy to carry and simple to operate.

The Freon sensor TGS3830 is a semiconductor gas sensor with a newly developed metal oxide by Figaro, mainly used to detect Freon. The sensitive element of this sensor is a tin dioxide (SnO2) semiconductor with low conductivity, and its conductivity will increase as the concentration of the target detection gas in the air rises. A simple circuit can convert the change in conductivity into an output signal corresponding to the gas concentration.

The refrigerant (R - 134a) gas sensor TGS3830 has extremely high sensitivity to R - 134a, which is widely used in air - conditioner and refrigerator refrigerants, and has a fast response speed. Therefore, the Freon sensor TGS3830 is an ideal sensor for a very excellent low - cost portable refrigerant leak alarm.

The refrigerated transportation link is the one we are most familiar with. Refrigerated transportation includes medium - and long - distance transportation and short - distance distribution of food and other logistics links. Refrigeration mainly involves several means of transportation such as railway refrigerated cars, road refrigerated vehicles, refrigerated ships, and refrigerated containers. Among them, road vehicles are the main force of refrigerated transportation in China at present.

During the refrigerated transportation process, temperature fluctuations are one of the main reasons for the decline in food quality. Therefore, the transportation tools should have good performance. While maintaining the specified low temperature, they should also maintain a stable temperature, which is particularly important for long - distance transportation.

The frozen sales link is the one that people usually come into contact with the most in daily life. Frozen sales include the frozen storage and sales of various cold - chain foods in the wholesale and retail links, which are jointly completed by manufacturers, wholesalers, and retailers.

With the rapid development of various chain supermarkets in cities, various chain supermarkets are becoming the main sales channels for cold - chain foods. In these retail terminals, a large number of refrigerated/freezer display cabinets and storage warehouses are used, gradually becoming an indispensable and important part of the complete food cold chain.

There are Three Types of Cold - chain Transportation: Fresh - keeping, Chilled, and Frozen

For the entire cold - chain logistics, people in the special - purpose vehicle industry are most concerned about the cold - chain transportation link. At present, refrigerated transportation in China is mainly carried out by road.

Cold - chain transportation can be divided into two categories according to the degree of food processing: primary agricultural products and processed foods. Primary agricultural products include vegetables, fruits, meat, poultry, eggs, milk, aquatic products, and flower products. Processed foods include frozen foods, packaged cooked foods such as poultry, meat, and aquatic products, ice - cream and dairy products, and fast - food ingredients.

Different foods have different temperature requirements for freshness - keeping, so the types of vehicles required for transportation are also different. According to the different temperatures required for food transportation, cold - chain transportation can be further divided into three types: fresh - keeping, chilled, and frozen.

Fresh - keeping goods include vegetables, flowers, fruits, fresh - keeping vaccines, and live aquatic products, and the required transportation temperature is around 2 - 8 degrees Celsius. Chilled goods mainly include acid - removed meat products, river and sea aquatic products, soy products, vaccine products, chocolate, etc., and the required transportation temperature is between 0 and 5 degrees Celsius. Frozen goods include frozen foods, frozen river and sea aquatic products, frozen meat, and frozen meat products, etc., and the required transportation temperature is between - 10 and - 18 degrees Celsius.

However, during the cold - chain transportation process, due to road bumps, it is easy to cause the joints of refrigeration equipment to loosen or even rupture, resulting in refrigerant leakage. Refrigerant leakage will affect the refrigeration effect and thus cannot guarantee the freshness - keeping quality. If the amount of refrigerant leakage is large, it is also easy to cause an explosion when encountering an open flame. Therefore, it is necessary to regularly check the points prone to leakage.

It is recommended to use a portable refrigerant leak detector to detect refrigerant leakage. It is easy to carry and simple to operate.

The Freon sensor TGS3830 is a semiconductor gas sensor with a newly developed metal oxide by Figaro, mainly used to detect Freon. The sensitive element of this sensor is a tin dioxide (SnO2) semiconductor with low conductivity, and its conductivity will increase as the concentration of the target detection gas in the air rises. A simple circuit can convert the change in conductivity into an output signal corresponding to the gas concentration.

The refrigerant (R - 134a) gas sensor TGS3830 has extremely high sensitivity to R - 134a, which is widely used in air - conditioner and refrigerator refrigerants, and has a fast response speed. Therefore, the Freon sensor TGS3830 is an ideal sensor for a very excellent low - cost portable refrigerant leak alarm.

Related Articles

- What Sensors Are Used for Leak Detection of R1234yf, the New Generation of Environmentally Friendly Refrigerant?

- What to Consider When Replacing R22 with Refrigerant R404A?

- Introduction to Inspection and Handling Methods for Refrigerant Leak in Cold Storage

- Four Combustible and Explosive Refrigerants: Precautions When in Use!

- Characteristics and Differences among Water System, Air System and Refrigerant System

- How to Judge the Refrigerant Charge Amount?

- How to Properly Extract Ammonia Refrigerant during Refrigeration Parts Repair

- Operating Principle and Standard Installation Steps of Multi - split Systems in Refrigerant Air - conditioning Systems

- Why Should Refrigerant Be Filled in Liquid Form? What Are the Filling Methods?

- What are the Cooling and Heating Pressures of an Air Conditioner? How to Calculate the Optimal Refrigerant Quantity?

- Maintenance Methods for Refrigerant Leak in Air - conditioner Outdoor Unit

- Operations and Precautions for Multi - split Air Conditioners: Blowing Debris, Air Tightness, Vacuum Drying, and Refrigerant Charging

- Multi-split air conditioner: Nitrogen charging for welding, pressure maintaining, vacuuming and refrigerant charging

- How to Check Refrigerant Leakage in Air Conditioning System?

- Scheme for the Use and Safety of Ammonia Refrigerants

- Precautions for Replacing Refrigeration Compressor Refrigerant Oil

- Introduction to the Relationship between Refrigerants and Cold Storage Temperatures

- Determining the Adequacy of Refrigerant Dosage in Fluorine Refrigeration Systems