Simple and Understandable Installation Method of Vibration - isolation Tubes for Refrigeration Compressors

2025-04-05

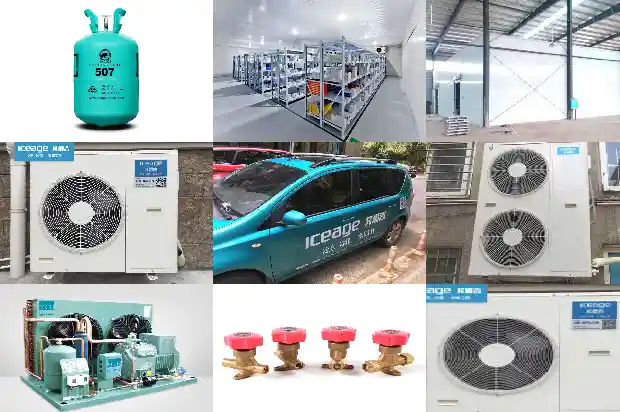

In some special industries, the requirements for refrigeration machine products are quite high. It is the demands from different enterprises and industries in the market that have enabled the refrigeration industry to develop rapidly to what it is today, with such a large number of users. As the output of refrigeration machine products increases, refrigeration technology is also facing challenges.

With the growing demand in the refrigeration market, people's attention to refrigeration machine products has significantly increased. Nowadays, when purchasing products, people are more concerned about the maintenance, upkeep, and operating methods of refrigeration machine products.

Friends who have used such products must know that during the operation of these products, there will be some vibrations and noises. These sounds can cause some inconvenience to our work. If you use the method we will talk about next, you will realize that the vibration - isolation tube of the refrigeration compressor has such a powerful function.

For compressors supported by vibration - isolation tube spring shock pads, flexible metal hoses (vibration - isolation tubes) are required to be installed on the suction and discharge pipes to prevent the vibration and noise transmitted through the refrigerant pipeline by the compressor. When the diameter is less than 12 millimeters, installing a vibration - isolation ring in the pipeline is sufficient. The vibration - isolation tube should be as close to the compressor as possible and be as parallel to the crankshaft as possible.

a. Install it in a straight line. Avoid static stretching or squeezing before and after installation, and avoid being in a straight line with the compressor.

b. Before the installation area, do not collide with hard objects. During use, the tube body should not rub against hard objects.

c.

a. Install it in a straight line. Avoid static stretching or squeezing before and after installation, and avoid being in a straight line with the compressor.

b. Before the installation area, do not collide with hard objects. During use, the tube body should not rub against hard objects.

c.

Moreover, the vibration - isolation tube can also be used for the connection between refrigeration machine compressors such as those in household air conditioners, freezers, freeze - dryers, etc.

Related Articles

- How to Operate the Cold - storage Distribution Box during Cold - storage Installation

- Eight Quality Problems in HVAC Installation Construction and Corrective Measures

- How Important Is the Installation Environment of Refrigeration Units? Just Do These 4 Points!

- Installation Precautions for the Source Components of Automatic Instruments in Refrigeration Units

- Precautions for the Installation of Automatic Instruments in Refrigeration Devices (Part One)

- Installation and Welding of Precision Air Conditioning Systems

- Comprehensive! Piping and Installation of VRF (Variable Refrigerant Flow) System

- What Issues Should Be Considered in the Installation of a Cold Storage?

- Installation, Inspection and Debugging of the Cold Storage Body

- Installation Precautions and Accessory Selection for Cold Storage Unit

- Matters Concerning the Installation of Parallel Units

- Advanced Guide! Design and Installation of Refrigeration System Pipelines

- What Are the Acceptance Standards for Cold Storage Design and Installation?

- What issues should be noted during the installation of a small - scale cold storage?

- Instructions for Welding and Drainage in the Installation of Refrigeration Equipment Pipelines

- What is the Correct Operation Method of the Distribution Box during Cold Storage Installation?

- What Issues Should Be Noted in Cold Storage Installation and Construction?

- What Special Requirements are There for the Installation of Tea Cold Storage?