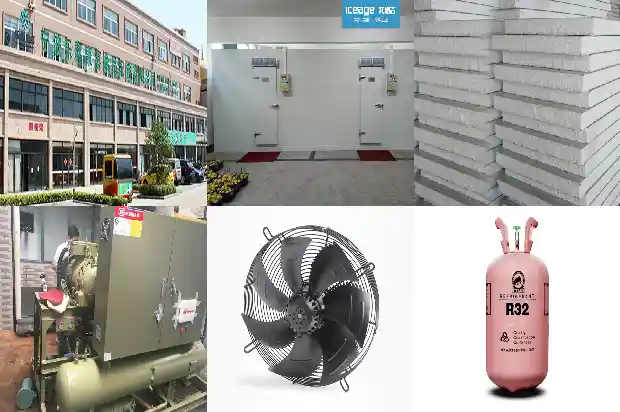

Steps for Building Logistics Cold Storages

2024-11-21

Warehouses that create suitable humidity and low temperature conditions by using cooling facilities. Also known as cold storage warehouses. They are places for processing and storing agricultural and livestock products.

Steps for constructing logistics cold storage warehouses:

- Site selection

Logistics storage cold storage warehouses are generally built in locations with relatively cheap land prices and convenient transportation according to the development of the enterprise itself. Heavy pollution sources should be avoided around the cold storage warehouses. The ground floor should be flat, solid, dry, and the surface is usually made of concrete.

The doors of the cold storage warehouses should open in the direction away from the wind. The opening direction can be towards the east and far away from pollution sources. The elevation of the ground floor should be higher than that of the surrounding ground to prevent water from entering the warehouses on rainy days.

Factors such as convenient transportation and connection with the market should be considered. It is better to build cold storage warehouses in shady places where hot winds are not frequent.

There should be good drainage conditions around the cold storage warehouses, the groundwater level should be low, and there should be an insulating layer under the cold storage warehouses, with good ventilation maintained. Keeping dry is very important for cold storage warehouses. In addition, before the construction of cold storage warehouses, the corresponding three-phase electricity should be set up in advance according to the power of the refrigeration units.

- Calculation of construction tonnage and area

Regarding the explanation of the volume coefficient, some goods are stacked full, while others are stacked in a way of directly piling up multiple layers of goods without using shelves, that is, stacking goods on top of other goods. In this way of stacking, more goods can be stacked, but it takes a longer time for the temperature and pressure at the center of the goods to reach the required temperature. As a result, the operating time of the refrigeration equipment will be longer. Relatively speaking, it will increase the electricity cost. If shelves are used reasonably and goods are stacked properly, it will be more energy-efficient and reduce the operating electricity cost. For large cold storage warehouses, it is recommended to use shelves reasonably, leave good air ducts, and ensure that both the placement of goods and the air ducts of the air coolers are in line with the air circulation.

It is easy to achieve an even temperature in the warehouses.

Related Articles

- Remember! 3 Steps to Calculate Central Air - conditioner Cooling Capacity

- Operating Principle and Standard Installation Steps of Multi - split Systems in Refrigerant Air - conditioning Systems

- What Key Steps Should Not Be Ignored in Installing an Air - source Heat Pump Heating System?

- System Airtightness Experiment Requirements and Steps

- Requirements and Maintenance for Building Meat Food Cold Storage

- What to Consider Before Building a Cold Storage Facility?

- What to note when building a seafood cold storage?

- Introduction to the Construction and Features of Cold Storage in Cold Chain Logistics

- Conditions are Required for the Construction of Small - sized Cold Storages

- Characteristics of Mini Cold Storages in Cold Storage Projects

- Differences Between Steel Structure Cold Storages and Multi-story Civil Engineering Cold Storages

- Some Simple Troubleshooting for Combined Cold Storages

- Temperature Requirements for Various Cold Storages

- Daily Maintenance Training for Users after Installation of Small and Medium-Sized Cold Storages

- Types and Temperature Requirements of Seed Cold Storages

- Principle of Multiple Storages in One Unit and Evaporation Pressure Regulation Methods

- What are the factors affecting large cold storages?

- How to Use Electricity Reasonably in Small Cold Storages?