Types of Refrigerants and Leak - detection Methods

2025-02-25

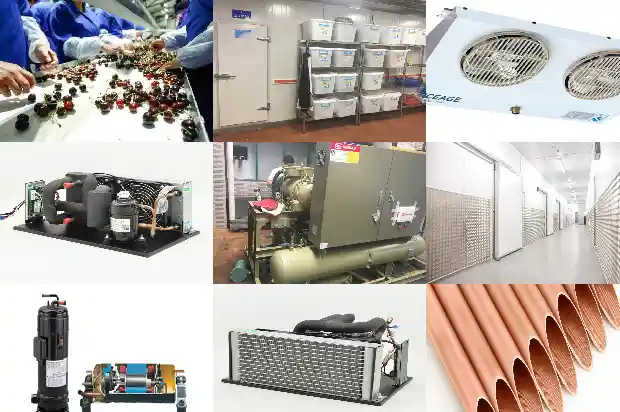

Refrigerants, also known as refrigeration working fluids, are commonly called "snow seeds" in some southern regions. It is a working substance that continuously circulates in the refrigeration system and realizes refrigeration through its own state changes.

Types of Refrigerants:

(1) Inorganic compounds. Such as water, ammonia, carbon dioxide, etc.

(2) Derivatives of saturated hydrocarbons, commonly known as Freon.

(3) Saturated hydrocarbons. Such as propane, isobutane, etc.

(4) Unsaturated hydrocarbons. Such as ethylene, propylene, etc.

(5) Azeotropic refrigerant mixtures. Such as R502, etc.

(6) Non - azeotropic refrigerant mixtures. Such as R407c, R410, etc.

(1) Inorganic compounds. Such as water, ammonia, carbon dioxide, etc.

(2) Derivatives of saturated hydrocarbons, commonly known as Freon.

(3) Saturated hydrocarbons. Such as propane, isobutane, etc.

(4) Unsaturated hydrocarbons. Such as ethylene, propylene, etc.

(5) Azeotropic refrigerant mixtures. Such as R502, etc.

(6) Non - azeotropic refrigerant mixtures. Such as R407c, R410, etc.

Usually, according to the standard evaporation temperature of the refrigerant, it is divided into three categories: high - temperature, medium - temperature, and low - temperature. The standard evaporation temperature refers to the evaporation temperature under standard atmospheric pressure, that is, the boiling point.

Low - pressure and high - temperature refrigerants:

The evaporation temperature is higher than 0°C, and the condensing pressure is lower than 29.41995×10⁴ Pa. This type of refrigerant is suitable for centrifugal refrigeration compressors in air - conditioning systems.

The evaporation temperature is higher than 0°C, and the condensing pressure is lower than 29.41995×10⁴ Pa. This type of refrigerant is suitable for centrifugal refrigeration compressors in air - conditioning systems.

Medium - pressure and medium - temperature refrigerants:

The evaporation temperature is - 50 ~ 0°C, and the condensing pressure is (196.113 ~ 29.41995)×10⁴ Pa. This type of refrigerant is generally used in piston refrigeration systems with ordinary single - stage compression and two - stage compression.

The evaporation temperature is - 50 ~ 0°C, and the condensing pressure is (196.113 ~ 29.41995)×10⁴ Pa. This type of refrigerant is generally used in piston refrigeration systems with ordinary single - stage compression and two - stage compression.

High - pressure and low - temperature refrigerants:

The evaporation temperature is lower than - 50°C, and the condensing pressure is higher than 196.

The evaporation temperature is lower than - 50°C, and the condensing pressure is higher than 196.

How to detect refrigerant leakage?

- Visual inspection: When an oil stain is found somewhere in the system, this place may be a leakage point. However, this method has significant drawbacks. Unless there is a large leakage point where the system suddenly breaks and the system leaks a liquid - colored medium, visual inspection for leakage cannot locate the point, because usually the leakage points are very tiny, and many parts of the refrigeration system are hardly visible.

- Bubble water or soapy water leakage detection: Charge the system with nitrogen at a pressure of 10 - 20 kg/cm², and then apply soapy water to various parts of the system. The place where bubbles appear is the leakage point. This is a common leakage detection method used by maintenance workers. However, the reach of a person's arm and the range of a person's vision are limited, and in many cases, the leakage point cannot be seen at all.

- Nitrogen - water leakage detection: Charge the system with nitrogen at a pressure of 10 - 20 kg/cm² and immerse the system in water. The place where bubbles appear is the leakage point. The obvious disadvantages of this method are that the water used for leakage detection can easily enter the system, causing corrosion to the materials in the system. At the same time, high - pressure gas may also cause greater damage to the system, and the labor intensity during leakage detection is also high.

- Fluorescent leakage detection: It uses the principle that the fluorescent leak detection agent emits bright yellow - green light under the irradiation of an ultraviolet/blue - light leak detection lamp to detect the fluid leakage in various systems. When using it, simply add the fluorescent agent to the system in a certain proportion. After the system operates for 20 minutes, put on special glasses and irradiate the outside of the system with the leak detection lamp. The leakage point will show yellow fluorescence.

- Gas differential pressure leakage detection: It uses the air pressure difference inside and outside the system, amplifies the pressure difference through a sensor, and expresses the leakage detection result in the form of numbers, sounds, or electronic signals. This method can only "qualitatively" tell whether the system leaks, but cannot accurately find the leakage point.

- Halogen lamp leakage detection: Ignite the leak detection lamp and hold the air tube on the halogen lamp. When the tube opening is close to the leakage point of the system, the flame color changes to purple - blue, indicating a large amount of leakage here. This method generates an open flame, which is not only dangerous, but also the combination of the open flame and the refrigerant will produce harmful gases. In addition, it is not easy to accurately locate the leakage point. Therefore, this method is hardly used now.

- Electronic leak detector leakage detection: The electronic leak detector is a reliable leak detection instrument. Due to its accurate leakage detection, it has quickly occupied the market in recent years. When using it, move the probe near the places where leakage is possible. When the leak detection device alarms, it indicates that there is a leakage here. Using an electronic leak detector to find leaks is currently the most scientific, simple, and rapid leakage detection method.

Related Articles

- Introduction to Basic Types of Cold Storage

- Cleaning Methods for Different Types of Condensers in Refrigeration Devices

- Types and Temperature Requirements of Seed Cold Storages

- Introduction to Types of Condensers in Cold Storage

- What are the important significances of a warm environment for various types of food?

- 5 Common Types of Refrigeration Compressors

- Four types of flammable and explosive refrigerants

- The characteristics and uses of 26 types of air conditioning refrigerants

- Four Combustible and Explosive Refrigerants: Precautions When in Use!

- Scheme for the Use and Safety of Ammonia Refrigerants

- Introduction to the Relationship between Refrigerants and Cold Storage Temperatures

- Performance of Eco-friendly Refrigerants 410A and R407C

- Introduction to Inspection and Handling Methods for Refrigerant Leak in Cold Storage

- Sensor for Refrigerant Leak Detection in Cold Chain Transportation

- Maintenance Methods for Refrigerant Leak in Air - conditioner Outdoor Unit

- What Sensors Are Used for Leak Detection of R1234yf, the New Generation of Environmentally Friendly Refrigerant?

- How to Check Refrigerant Leakage in Air Conditioning System?

- 4 Points on Causes of Water Leakage in Closed Cooling Towers