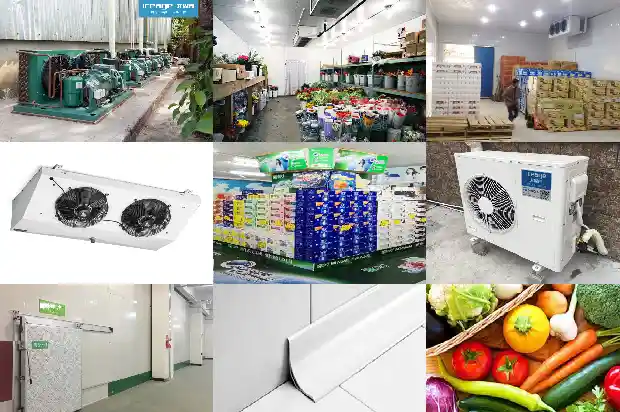

What Are the Acceptance Standards for Cold Storage Design and Installation?

2025-02-25

When it comes to the acceptance of a newly - built cold storage, there are surely some concerns.

Installation and Acceptance Standards for Cold Storage Design

- The installation of the cold - storage panels should be tight.

The inner and outer metal panels of the cold - storage surface shall not be connected to prevent the formation of cold bridges. The sealant between the cold - storage panels should be applied evenly.

- The cold - storage door should be installed straight, tightly closed, and should open and close smoothly.

- The refrigeration compressor units should be of the same color, reasonably arranged, and the installation of each type of unit should be consistent.

- The diameter selection of each component in the refrigeration system should meet the requirements of the cold - storage design.

- The installation position of the refrigeration unit should be convenient for engineers and technicians to observe, maintain, and adjust.

- The thermal bulb of the expansion valve should be insulated. The installation positions of the fan, expansion valve, and filter should be convenient for engineers and technicians to repair.

- The return air pipeline of the air cooler should have a slope. An oil - return bend should be installed at the fan outlet. When choosing the pipeline route, the resistance in the pipeline and aesthetics should be considered.

- When the compressor is running, check the oil level, base vibration, running sound, suction temperature, discharge temperature, motor temperature, crankcase temperature, high and low pressures, running current, air - outlet direction, the frosting conditions of the air cooler and expansion valve, and the effectiveness of the pressure protection and motor thermal overload protection.

- Check whether the design of the computer - controlled temperature meets the usage requirements. The electrical control components should act sensitively. The electrical coils should not heat up or produce an AC hum. The wire connections should be firm, and the surface temperature of the wire should not exceed 40°C.

- In the cold - storage installation, the wire conduits and refrigeration pipelines should be horizontal and vertical, without crossing or unevenness. A certain distance should be left. All pipelines should be firmly fixed with metal clips to avoid resonance and mutual friction.

The entire project should be constructed according to the design.

Related Articles

- Differences, Requirements and Standards between Pharmaceutical Cold Storage and Conventional Cold Storage

- What issues should be noted during the installation of a small - scale cold storage?

- What Are the Common Reasons for Difficulties in Cooling a Cold Storage?

- Introduction to Inspection and Handling Methods for Refrigerant Leak in Cold Storage

- How to Resolve the Scuffing Issue of Cold Storage Compressors

- What is the Correct Operation Method of the Distribution Box during Cold Storage Installation?

- Reasons for Frost Formation in Cold Storage and Defrosting Methods

- What Are the Differences Between R22 and R404A Cold Storage Systems?

- Maintenance Methods for Small Modular Cold Storage Failures

- What Vacuum Requirements Do Cold Storage Equipment Have?

- What Issues Should Be Noted in Cold Storage Installation and Construction?

- Common Malfunctions in the Operation of Cold Storage

- What Special Requirements are There for the Installation of Tea Cold Storage?

- How to Solve the Problem of Frequent Shutdown and Startup of Cold Storage Compressors?

- What are the Storage Conditions of Nectarine in Controlled Atmosphere Cold Storage?

- What Precautions Should Be Taken When Using a Fresh - keeping Cold Storage in Summer?

- Introduction to Basic Types of Cold Storage

- Common Cold - chain Storage Methods for Fruit and Vegetable Cold Storage