What Are the Common Reasons for Difficulties in Cooling a Cold Storage?

2025-02-20

The capacity of a cold storage should be designed according to the maximum amount of agricultural products to be stored throughout the year. This capacity is calculated based on the volume occupied by the stored products when stacked in the cold storage, along with the aisle space between rows, the space between the stack and the walls and ceiling, and the gaps between packages. After determining the capacity, the length and height of the cold storage are then determined. When designing a cold storage, necessary auxiliary buildings and facilities such as workrooms, packaging and sorting rooms, tool storage rooms, and loading and unloading platforms should also be considered to ensure the quality of the cold storage.

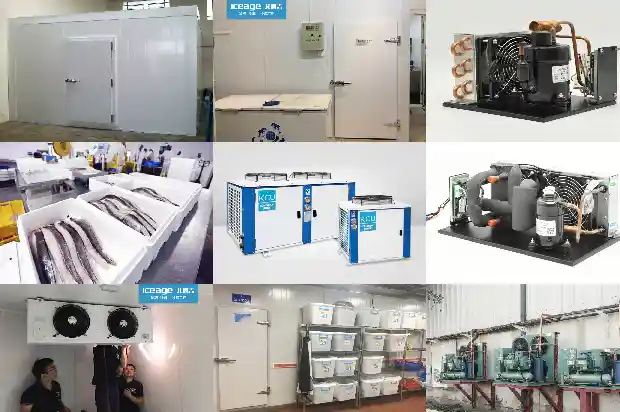

The selection and installation of insulation materials are of great importance to the quality of the cold storage. The insulation materials for the cold storage must be selected according to local conditions, with both good insulation performance and economic practicality. There are several types of insulation materials. One type is processed into fixed - shaped and sized panels with fixed length, width, and thickness. Corresponding - sized panels can be selected according to the installation needs of the cold - storage body. Generally, 10 - centimeter - thick panels are used for high - and medium - temperature cold storages, and 12 - centimeter or 15 - centimeter - thick panels are used for low - temperature cold storages and freezing cold storages. Another type is polyurethane sprayed and foamed. The material is directly sprayed onto the already - built brick or concrete warehouse. After shaping, it is both moisture - proof and heat - insulating. The insulation - material panels include polyurethane, polystyrene, etc. Polyurethane has good heat - insulation performance and does not absorb water, but it has a relatively high cost. Polystyrene has strong water - absorption and poor heat - insulation performance, but it has a relatively low cost. The structure of modern cold storages is developing towards pre - fabricated assembly. The cold - storage components including the moisture - proof layer and the insulation layer are made and assembled on - site. Its advantages are convenient and rapid construction, and it can be movable, but the construction cost is relatively high. The selection of the refrigeration system is of the utmost importance to the quality of the cold storage. The selection of the cold - storage refrigeration system mainly focuses on the selection of the compressor and the evaporator. The refrigeration system is the core of the cold storage and is mainly composed of four parts: the compression system, the condensation system, the evaporation system, and the regulating valve. In addition, there are auxiliary components such as fans, ducts, and instruments. The entire refrigeration system is a sealed circulation loop. The refrigerant circulates in this sealed system. According to needs, the supply amount and the number of times it enters the evaporator are controlled to obtain suitable low - temperature conditions. The compressor is the heart of the refrigeration system, pushing the refrigerant to circulate in the system.

The function of the condenser is to remove the heat from the compressed gaseous refrigerant and condense it into a liquid refrigerant. The cooling methods of the condenser include air - cooling, water - cooling, and a combination of air and water. Air - cooling is only applied in small - scale cold - storage refrigeration equipment. The function of the evaporator is to provide cold to the cold storage. The evaporator is installed inside the cold storage. A blower is used to blow the cooled air to all parts of the cold storage. In large - scale cold storages, air ducts are often used to connect the evaporator to extend the air - supply distance and make the temperature drop in the cold storage more uniform.

Under normal circumstances, fully - enclosed compressors are mainly selected for small - scale cold storages.

The function of the condenser is to remove the heat from the compressed gaseous refrigerant and condense it into a liquid refrigerant. The cooling methods of the condenser include air - cooling, water - cooling, and a combination of air and water. Air - cooling is only applied in small - scale cold - storage refrigeration equipment. The function of the evaporator is to provide cold to the cold storage. The evaporator is installed inside the cold storage. A blower is used to blow the cooled air to all parts of the cold storage. In large - scale cold storages, air ducts are often used to connect the evaporator to extend the air - supply distance and make the temperature drop in the cold storage more uniform.

Under normal circumstances, fully - enclosed compressors are mainly selected for small - scale cold storages.

Related Articles

- Analysis of Seven Reasons for Ice Formation in Computer Room Air Conditioners

- Reasons for Frost Formation in Cold Storage and Defrosting Methods

- What Are the Reasons for Insufficient Air Output of Screw Air Compressors?

- Reasons for Pump Body Failures in Cold Storage Compressors

- What are the reasons for the inactivity of the automotive air conditioning compressor? What are the common faults?

- What are the reasons for the frequent start-up and tripping of the refrigerated air dryer in the cold storage?

- Reasons and Solutions for High and Low Condensing Pressure in Air-cooled and Water-cooled Systems

- 15 Reasons for Excessive Temperature Rise of Motors

- Reasons for Installing Thermal Insulation Layers in Cold Storages

- What are the reasons for the poor oil return of screw compressors?

- 7 Reasons for Low Air Pressure in Cold Water Unit

- Reasons for Higher Cost of Controlled Atmosphere Cold Storage than Ordinary Cold Storage

- Five potential reasons for the deteriorating performance of car air conditioning

- Nine common reasons for compressor damage

- Introduction to Inspection and Handling Methods for Refrigerant Leak in Cold Storage

- How to Resolve the Scuffing Issue of Cold Storage Compressors

- What is the Correct Operation Method of the Distribution Box during Cold Storage Installation?

- What Are the Differences Between R22 and R404A Cold Storage Systems?