What Are the Differences Between Chillers and General Water - cooled Equipment?

2025-02-16

Today, with the rapid development of modern industrial technology, in order to improve production efficiency, enhance product quality, and reduce production costs, there is an increasingly high demand for temperature control in the production process.

Generally, water - cooling methods (i.e., using natural water and cooling towers for heat dissipation) cannot achieve the goal of high - precision and high - efficiency temperature control. This is because both natural water and cooling - tower heat dissipation are inevitably affected by the natural temperature.

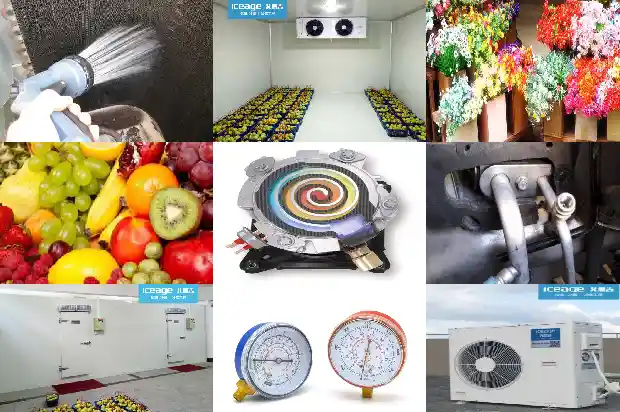

Chillers are completely different from general water - cooled equipment. Since chillers have a completely independent refrigeration system, they are never affected by temperature and the environment. The water temperature can be adjusted and controlled within the range of 5°C - 30°C, thus enabling high - precision and high - efficiency temperature control.

In the 21st century, with the rapid development of modern industrial technology, to improve production efficiency, enhance product quality, and reduce production costs, the requirements for temperature control in the production process are getting higher and higher. Therefore, industrial chillers are needed in various industries:

Chillers can be used in conjunction with vacuum equipment. Such chillers also meet the requirements of high - quality vacuum equipment, such as molecular pumps and small - scale vacuum coating machines.

Chillers can be used in conjunction with medical laser equipment. The unique water - quality treatment features of such chillers make them an ideal choice for medical laser equipment and for supporting laboratory equipment.

During the use of chillers, the following points must be noted: First, a liquid medium should be added to the tank before use. Second, the working power supply should be determined according to the model of this machine. The power of the power supply should be greater than or equal to the total power of the instrument, and the power supply must be well - grounded. Third, the chiller should be placed in a dry and ventilated place, with a distance of 400mm from the rear and both sides to obstacles. Finally, after using the chiller, turn all switches to the off state, unplug the power plug, and use a suction ball and a hose to suck dry the liquid in the tank.

Chillers can be used in conjunction with vacuum equipment. Such chillers also meet the requirements of high - quality vacuum equipment, such as molecular pumps and small - scale vacuum coating machines.

Chillers can be used in conjunction with medical laser equipment. The unique water - quality treatment features of such chillers make them an ideal choice for medical laser equipment and for supporting laboratory equipment.

During the use of chillers, the following points must be noted: First, a liquid medium should be added to the tank before use. Second, the working power supply should be determined according to the model of this machine. The power of the power supply should be greater than or equal to the total power of the instrument, and the power supply must be well - grounded. Third, the chiller should be placed in a dry and ventilated place, with a distance of 400mm from the rear and both sides to obstacles. Finally, after using the chiller, turn all switches to the off state, unplug the power plug, and use a suction ball and a hose to suck dry the liquid in the tank.

Related Articles

- What Are the Differences Between R22 and R404A Cold Storage Systems?

- Characteristics and Differences among Water System, Air System and Refrigerant System

- What Are the Differences Between Cold Storage and Freezer?

- Differences Between Steel Structure Cold Storages and Multi-story Civil Engineering Cold Storages

- Temperature Gradient Differences between Deep Foundation and Surface of Civil Cold Storage

- Differences, Requirements and Standards between Pharmaceutical Cold Storage and Conventional Cold Storage

- Maintenance Strategies for the Working Cycle and Electrical Automatic Control of Chillers

- What are Refrigeration Equipment? What's the Principle of Chillers?

- Common Faults of Industrial Chillers

- Can You Solve These 4 Common Issues of Industrial Chillers?

- Common Faults and Corresponding Solutions of Chillers During Use

- How to Install and Maintain Industrial Chillers?

- Introduction to Lithium Bromide Absorption Chillers

- 8 Maintenance Procedures for Industrial Chillers

- Effective Measures to Prevent Compressor Failures in Industrial Chillers

- Reference Points for Selection of Screw - type Chillers

- How to accurately choose water-cooled and air-cooled chillers?

- When to Consider Replacing Industrial Chillers