What Issues Should Be Noted in Cold Storage Installation and Construction?

2025-01-11

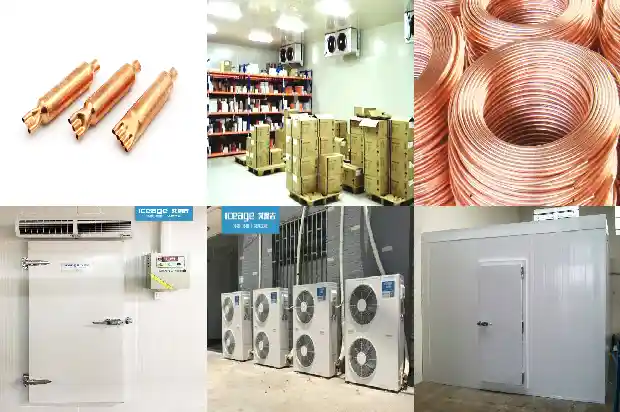

- Installation of the cold storage unit

The closer the location of the cold storage unit is to the evaporator, the better.

It should be easy to maintain and have good heat dissipation. If it is moved outdoors, a rain shelter needs to be installed. Anti - vibration gaskets should be placed at the four corners of the cold storage unit position. It should be installed horizontally and firmly and not easily bumped into by people.

- Arrangement of copper pipes of the cold storage unit

All copper pipes should be separately passed through insulating pipes and bundled together with wires in the same direction using air - conditioner binding tapes. Try to make the pipelines go straight and fix them in sections. - Installation of the radiator of the cold storage unit

The closer the radiator is to the cold storage unit, the better. It can be placed slightly above the cold storage unit. The installation position of the radiator should have an excellent heat - dissipation environment. The air intake should not face the air outlet of other equipment, especially oily gas. The air outlet should not be short - circuited and should not face other windows (especially residential windows) and equipment. It should be 2M high from the ground and installed horizontally and firmly. - Installation of pipelines and circuits of the cold storage unit

After all copper pipes are welded, pressure - tested and purged, install insulating pipes. Pay attention to using glue to firmly seal all connection gaps of the insulation materials and bundle them with binding tapes. Wires and cables should be protected by separate wire pipes or wire troughs, and fixed brackets should be set in sections according to specifications. Weak - current signal lines should be routed separately from strong - current lines, and shielding treatment should be carried out if necessary. - Since the cold storage unit and the air cooler are pressure - tested and sealed in the factory, there should be pressure when they are opened. Check for any leaks. The copper pipes leaving the factory should have dust - proof measures at both ends. During construction, pay attention to sealing at any time to prevent water and dust from entering the pipes. The condenser, the main cold storage unit and the air cooler are connected with copper pipes by welding. The joints should be firm and beautiful.

- Configure wires according to the performance of each electrical appliance. The wire diameter should meet the requirements, the joints should be firm, and if wire - protection pipes are required, they should not be omitted. The power connection should be correct.

When the wire enters the wiring box hole of the evaporator, it needs to be sealed with silicone. If the lamp is powered by more than 36V electricity, a grounding wire is required. The power supply entering the electrical cabinet of the cold storage unit should be three - phase five - wire system with reliable grounding.

- The temperature - display probe of the cold storage unit penetrates into the air return opening of the evaporator in the cold storage and is suspended. The defrosting temperature probe of the cold storage unit penetrates through another hole into the air return opening of the evaporator in the cold storage, and the probe is inserted into the fins (not close to the electric heating tube).

- The balance hole (pressure - equalizing valve, also known as the balance window) should not be installed in a conspicuous place or on the vertical plate of the air outlet. The hole should be opened 200MM down from the upper part of the vertical plate of the cold storage. For all components that penetrate the cold storage panel, the gaps between the cold storage panel and the components need to be sealed with sealant.

Related Articles

- How to Calculate Refrigeration Load? And What Are the Issues?

- Can You Solve These 4 Common Issues of Industrial Chillers?

- Frosting and Defrosting Issues of Air - cooled Heat Pumps

- Common Issues in Chiller Operation and Solutions

- Common Issues in Refrigeration Systems

- Common Issues with Refrigeration Equipment: What to Do?

- Common Issues to Pay Attention to During Cold Room Installation and Construction

- Introduction to the Components of a Cold Storage Unit and Common Issues in Cold Storage Units

- What Are the Common Reasons for Difficulties in Cooling a Cold Storage?

- Introduction to Inspection and Handling Methods for Refrigerant Leak in Cold Storage

- How to Resolve the Scuffing Issue of Cold Storage Compressors

- What is the Correct Operation Method of the Distribution Box during Cold Storage Installation?

- Reasons for Frost Formation in Cold Storage and Defrosting Methods

- What Are the Differences Between R22 and R404A Cold Storage Systems?

- Maintenance Methods for Small Modular Cold Storage Failures

- What Vacuum Requirements Do Cold Storage Equipment Have?

- Common Malfunctions in the Operation of Cold Storage

- What Special Requirements are There for the Installation of Tea Cold Storage?