What Sensors Are Used for Leak Detection of R1234yf, the New Generation of Environmentally Friendly Refrigerant?

2024-12-15

With the current increase in global environmental protection requirements, the replacement of HFC refrigerants has gradually been put on the agenda.

In mobile vehicle air conditioners, the HFC refrigerant R134a is widely used due to its excellent refrigeration performance and pressure curve. However, since the HFC-134A refrigerant belongs to the third-generation refrigerant and has a relatively high Global Warming Potential (GWP) value, it has already been listed as a phased-out substance in the European Union. The substitute for the R134a refrigerant is R1234YF. It has a refrigerant and pressure curve similar to that of R134a and is a very ideal substitute product. Judging from current regulations, vehicles exported to the European Union must be charged with the R1234YF refrigerant.

So, what is the R1234yf refrigerant like?

The R1234yf refrigerant, tetrafluoropropene, as a single working fluid refrigerant, has excellent environmental parameters. Its Global Warming Potential (GWP) is 4, its Ozone Depletion Potential (ODP) is 0, and its Life Cycle Climate Performance (LCCP) is lower than that of R134a. Its atmospheric decomposition products are the same as those of R134a. Moreover, its system performance is better than that of R134a. If R1234yf is chosen to replace the R134a refrigerant, automobile manufacturers can continue to use the original Mobile Air-Conditioning (MAC) system. Therefore, R1234yf is regarded as a new-generation automobile refrigerant substitute with great potential and has been accepted by automobile manufacturers in Western Europe at present.

The boiling heat transfer performance of R1234yf is slightly better than that of R134a, and the pressure drop during the condensation process is 5% - 10% lower than that of R134a, which is better than the R134a system. In many simulation and experimental studies on the R1234yf and R134a systems, the heat pump performance of R1234yf is slightly lower than that of R134a, but it can be made very close to or even exceed that of R134a by optimizing components, strengthening gas injection, and improving working conditions. The low-pressure saturated pressure of R1234yf is about 15% higher than that of R134a, which can be adapted to higher compressor speeds. Its heating performance at low temperatures is better than that of R134a, and the relatively low compressor exhaust temperature makes the system work more stably. The effect of strengthening gas injection is also better than that of R134a.

Application fields of R1234yf

R1234yf can be applied in fields such as refrigerator refrigerants, fire extinguishing agents, heat transfer media, propellants, foaming agents, blowing agents, gas media, sterilant carriers, polymer monomers, particle-removing fluids, carrier gas fluids, grinding and polishing agents, replacement desiccants, electrical cycle working fluids, and so on.

R1234yf can be applied in fields such as refrigerator refrigerants, fire extinguishing agents, heat transfer media, propellants, foaming agents, blowing agents, gas media, sterilant carriers, polymer monomers, particle-removing fluids, carrier gas fluids, grinding and polishing agents, replacement desiccants, electrical cycle working fluids, and so on.

The research on the R1234yf refrigerant started in 2007, and it was concluded in 2010 that this refrigerant could be safely used in automobiles as a new type of refrigerant. R1234yf is regarded as an alternative refrigerant for automobile air conditioners that meets both environmental protection and customer requirements. It is produced and put on the market by DuPont and Honeywell.

The European Union has issued a regulation requiring that all new cars produced and sold within Europe must use the new environmentally friendly R1234yf as the automobile air conditioner refrigerant to replace the previously used refrigerant R134a (the refrigerant circulates in the sealed air conditioning system, and the quality of the refrigerant is very important for the entire system) starting from the beginning of that year. The reason is that the Global Warming Potential (GWP) of R1234yf is only 4, while that of the previous-generation refrigerant R134a is as high as 1300. In comparison, the new refrigerant basically has little impact on global warming.

Since January 1, 2017, refrigerants with a GWP greater than 150 have been prohibited from being used in all new cars produced and sold within Europe. It can be seen that the gradual phasing out of R134a (GWP = 1300), which is widely used as an automobile air conditioner refrigerant, will become an inevitable trend. The fourth-generation refrigerants R1234yf and R1234ze launched by DuPont and Honeywell are regarded as new-generation environmentally friendly refrigerants to replace R134a, so R1234yf will be first applied to automobile air conditioners.

However, although the new automobile air conditioner refrigerant R1234yf releases less CO2 than the previous-generation refrigerant, it has very significant safety hazards. On a test section of Mercedes-Benz in Stuttgart-Untertürkheim, when cars using the new refrigerant were being tested, in 14 tests, there were at least ten times when the refrigerant caught fire when encountering high-temperature engine parts, and there were continuous fire incidents for five days. This is because when a car using this refrigerant has a serious collision, it will catch fire due to the rupture of the air conditioner refrigerant pipeline, and when burning, it will also release the toxic gas hydrogen fluoride.

Moreover, wherever the refrigerant exists, there is a possibility of leakage. In the automobile air conditioning system, throughout the entire cycle of the refrigerant, parts such as the compressor, evaporator, condenser, high-pressure pipe, and low-pressure pipe may all have poor sealing, resulting in the escape of the refrigerant.

Therefore, for the leakage of the new air conditioner refrigerant R1234yf, the technical engineers of Icstation recommend the special Freon sensor TGS2630 for detecting the leakage of refrigerant. The Freon sensor TGS2630 is widely used to detect refrigerants R404a and R410a, which are commonly used in air conditioners and refrigeration equipment. It also has high sensitivity to non-flammable refrigerant gases R32 and R1234yf that can prevent climate warming. Due to the built-in filter layer, it has very low sensitivity to volatile alcohol (a common interfering gas in the living environment), demonstrating high selectivity for non-flammable refrigerants. Since the sensitive element has a very small volume, the heater current of TGS2630 only needs 56 mA, and its housing adopts the standard TO-5 metal package.

At the same time, Icstation also provides the Freon sensor TGS3830. The Freon sensor TGS3830 is a semiconductor gas sensor made of metal oxide developed by Figaro. It is mainly used to detect Freon R-134a. The sensitive element of this sensor is a tin dioxide (SnO2) semiconductor with low conductivity. Its conductivity will increase as the concentration of the target detection gas in the air rises. A simple circuit can convert the change in conductivity into an output signal corresponding to the gas concentration. Moreover, the gas-sensitive bead is very tiny, and the power consumption of the heater only needs 120 mW.

The refrigerant (R-134a) gas sensor TGS3830 has extremely high sensitivity to R-134a, which is widely used in air conditioner and refrigerator refrigerants, and has a fast response speed. Therefore, the Freon sensor TGS3830 is an ideal sensor for an excellent low-cost portable refrigerant leakage alarm.

Related Articles

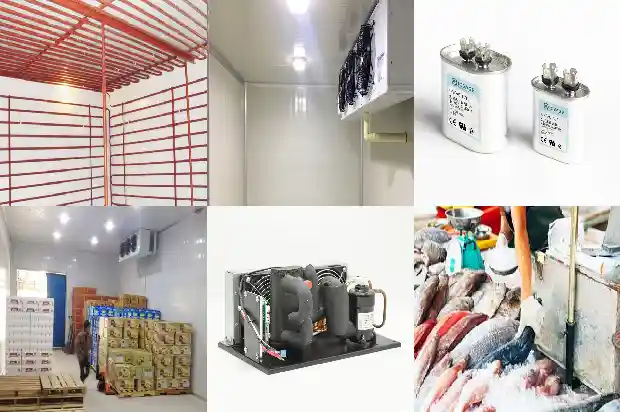

- Introduction to Inspection and Handling Methods for Refrigerant Leak in Cold Storage

- Sensor for Refrigerant Leak Detection in Cold Chain Transportation

- Maintenance Methods for Refrigerant Leak in Air - conditioner Outdoor Unit

- How to Check Refrigerant Leakage in Air Conditioning System?

- 4 Points on Causes of Water Leakage in Closed Cooling Towers

- Analysis of Causes for Safety Valve Leakage

- What are the hazards of water leakage in a cold storage?

- Oil Cooling Methods and Oil Leakage Operations for Screw Compressors

- Liquid Level Detection and Control of Flooded Evaporators

- Are you familiar with the detection and maintenance methods of air conditioner components?

- What to Consider When Replacing R22 with Refrigerant R404A?

- Four Combustible and Explosive Refrigerants: Precautions When in Use!

- Characteristics and Differences among Water System, Air System and Refrigerant System

- How to Judge the Refrigerant Charge Amount?

- How to Properly Extract Ammonia Refrigerant during Refrigeration Parts Repair

- Operating Principle and Standard Installation Steps of Multi - split Systems in Refrigerant Air - conditioning Systems

- Why Should Refrigerant Be Filled in Liquid Form? What Are the Filling Methods?

- What are the Cooling and Heating Pressures of an Air Conditioner? How to Calculate the Optimal Refrigerant Quantity?