What to Do When the Condensing Pressure of the Cold Storage Is Too Low in Winter?

2025-03-03

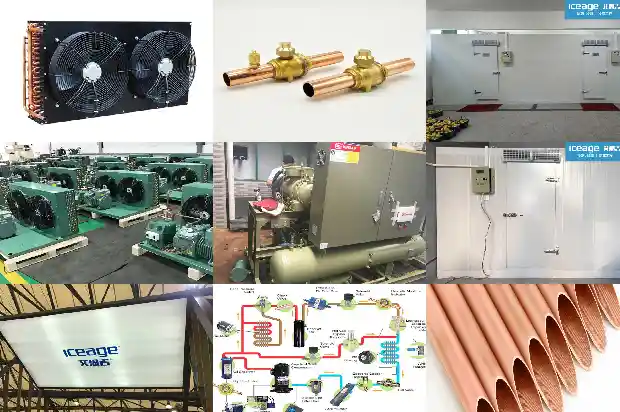

First, we need to understand two concepts: condensing temperature and condensing pressure. The condensing temperature refers to the saturation temperature at which the refrigerant vapor in the condenser condenses under a certain pressure. The condensing temperature is not equal to the temperature of the cooling medium, and there is also a heat transfer temperature difference between them.

The condensing pressure refers to the pressure at which the refrigerant condenses from a gas to a liquid in the condenser. Since the pressure inside the condenser in the refrigeration system cannot be measured, and in fact, the pressure drop of the refrigerant in the exhaust pipe and the condenser is very small, whether in design or commissioning, the exhaust pressure is often approximated to the condensing pressure.

During the operation of the refrigeration device, the condensing pressure has a great influence on the system performance. When the condensing pressure (or condensing temperature) is high, the compression ratio increases, the volumetric efficiency decreases, the refrigeration capacity decreases, and the power consumption increases. The exhaust temperature rises, and the higher the condensing pressure, the greater the degree of its adverse effects. The phenomenon of high condensing pressure mainly occurs in summer, and at this time, the condensing pressure should be reduced as much as possible to ensure the economy and reliability of the system operation.

However, for refrigeration devices that operate throughout the year, such as air conditioning machine rooms, refrigeration and cold storage (cold storage) and other equipment, the phenomenon of too low condensing pressure may occur during winter operation. When the condensing pressure is too low, the pressure difference before and after the expansion valve is too small, and the capacity of the expansion valve decreases, resulting in insufficient liquid supply capacity. The evaporator is short of liquid, and the refrigeration capacity of the system drops significantly, thus causing faults in the refrigeration system.

In the refrigeration system, if the condenser is installed outdoors, the exhaust pressure (condensing pressure) of the system is often relatively low in winter (or in a low-temperature environment). This situation is more common in the north, and it also exists for air conditioners as well as other equipment (such as cold storage);

Too low a condensing pressure will make it impossible for the expansion valve to obtain a sufficient pressure drop at both ends, and it is difficult to provide an appropriate amount of refrigerant to the evaporator. On the one hand, the refrigeration capacity of the system cannot meet the requirements, and on the other hand, it will also cause frequent low-pressure alarms and other faults in the system.

The methods for adjusting the condensing pressure vary for different condensers. The following are several methods to increase the condensing pressure at low temperatures:

- Install an Exhaust Pressure Controller:

The condensing fan can be operated intermittently. When the pressure is too low, the fan is turned off; when the pressure is too high, the fan is turned on. It is simple and easy to use, and the technology is mature. The controller used is a pressure controller, which can control the intermittent start and stop of the fan.

Generally, for small-capacity units, two or more fans are used. One of the fans is normally open, and the remaining fans are controlled by the pressure controller. The start or stop of one or more fans is controlled according to the high and low condensing pressure. - Fan Speed Control:

The method of fan speed control is also a relatively mature operation method. The main electrical components used are an inverter (three-phase) or a speed controller (single-phase). The main working principle is that the feedback signal (1~5V or 4-20mA signal) of the exhaust pressure (condensing temperature) is input into the inverter (speed controller), and the inverter outputs (0~50Hz) to the fan according to the setting to achieve the variable-speed operation of the fan. This is also a common control method, which is simple and easy to use, but the cost is relatively high. - Air Volume Control Device:

The main component is a louver-type air volume control device. The louver device can be installed either at the air inlet or at the air outlet. The principle is to use a piston-type regulating damper driven by high-pressure refrigerant.

This control device can obtain a stable exhaust pressure just like the fan speed controller; most importantly, the inlet pressure of the expansion valve will not fluctuate greatly like in the method of intermittent fan operation.

- Condenser Overflow Device:

The working principle of the condenser overflow device is to use an excessive amount of refrigerant to increase the condensing pressure of the system. The condenser overflow device is used in warm or low-temperature environments. It sends a large flow of refrigerant from the liquid receiver to the condenser. By using the excessive refrigerant, the condensing pressure of the system is increased, thus avoiding the fault of too low condensing pressure at low temperatures.

The advantage of the condenser overflow device is that it can obtain a stable condensing pressure with small fluctuations; the condenser is almost filled with liquid refrigerant, making the inlet temperature of the expansion valve lower than the condensing temperature to achieve supercooling, thereby increasing the refrigeration capacity of the refrigeration system. - Water Flow Regulating Valve:

There are two types of water flow regulating valves: pressure control type and temperature control type:

Pressure Control Type Water Flow Regulating Valve: Using the condensing pressure as a signal, it proportionally regulates the flow rate of the cooling water. The higher the condensing pressure, the larger the valve opening; the lower the condensing pressure, the smaller the valve opening. When the opening is reduced below the opening pressure of the valve, the valve automatically closes and cuts off the supply of cooling water. After that, the condensing pressure will rise.

When it rises above the opening pressure of the valve, the valve automatically opens again.

Temperature Control Type Water Flow Regulating Valve: The working principle is the same as that of the pressure control type. The difference is that it uses a temperature sensing bulb to detect the temperature change at the outlet of the cooling water, converts the temperature signal into a pressure signal in the temperature sensing bulb, and regulates the flow rate of the cooling water. The temperature control type water flow regulating valve does not respond as quickly as the pressure control type water flow regulating valve, but it works stably, and the sensor is simple and convenient to install. - Condenser Heat Transfer Area Adjustment:

When there are multiple sets of condensers, the on/off state of the solenoid valves connected in series on the channels of each set of condensers can be used to open or cut off the condenser passages to change the heat transfer area of the condenser. This method is often used in multi-connected units to ensure that the condensing pressure can be stabilized within the required range when the compressor adjusts its capacity within a large range. - Insulation Treatment and Blocking of the Air-cooled Condenser:

For some small refrigeration equipment with condensers placed outdoors, when the high pressure is low in winter, the power supply to the air-cooled condenser motor can also be cut off. At the same time, part of the fins can be blocked, or a simple carton can be covered to give it a certain insulation performance, so as to increase the condensing pressure.

Related Articles

- Winter Approaches: How to Solve the Low High - pressure Issue of Air - cooled Condensing Units?

- Why Does the Evaporation Temperature of the Refrigeration System Drop Too Low? And Why is the Condensing Pressure Too High?

- Reasons and Solutions for High and Low Condensing Pressure in Air-cooled and Water-cooled Systems

- Influence of Condensing Temperature Variation on Vapor Compression Refrigeration System

- A Detailed Analysis of the Nine Reasons for the Low Pressure in the Refrigeration System!

- Principles and Applications of Common Pressure Control and Pressure Regulating Valves

- What Impact Does Pressure Have on the Refrigeration System?

- What Are the Common Causes of High - pressure Faults in Chillers?

- Common Pressure Valves and Protection Devices in Refrigeration Units

- How to Troubleshoot and Repair High - pressure Protection of Air - cooled Units?

- How to Read the High - and Low - Pressure Gauges of Refrigeration Air - conditioners?

- Air - conditioner Low - pressure Alarm? These Nine Common Causes

- What are the Cooling and Heating Pressures of an Air Conditioner? How to Calculate the Optimal Refrigerant Quantity?

- Common Causes and Analysis of High and Low Pressure Alarms

- Obscure Knowledge of Static Pressure, Dynamic Pressure, Latent Heat and Sensible Heat in the HVAC Industry

- Multi-split air conditioner: Nitrogen charging for welding, pressure maintaining, vacuuming and refrigerant charging

- What Causes Noise in Pressure Reducing Valves?

- Pressure Gauge in Refrigeration Equipment