5 Common Types of Refrigeration Compressors

2024-08-30

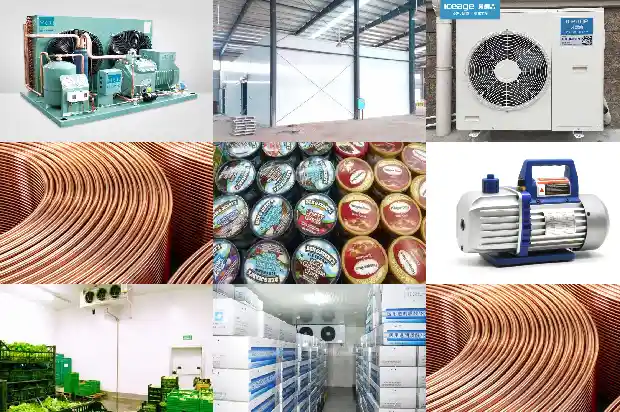

- Semi-hermetic piston refrigeration compressor

Among various types of refrigeration compressors, the piston compressor is the earliest one that came out and is still widely used today. For example, semi-hermetic piston refrigeration compressors are widely used in refrigeration and freezing equipment. Characteristics of semi-hermetic piston refrigeration compressors: They have a wide pressure range and refrigeration capacity, low material requirements, are relatively mature in technology, and the compressor system is relatively simple, but they are very afraid of liquid hammer.

Common faults of semi-hermetic piston refrigeration compressors are in two aspects: mechanical faults and electrical faults. Mechanical faults commonly include wear or damage to connecting rods, crankshafts, valve plates and valve discs; electrical faults are more common in short circuits, open circuits and burnout of motor windings.

- Twin-rotor refrigeration compressor

Twin-rotor compressors are now widely used in home appliances, and the export scale of rotor compressors is increasing year by year. The compound growth rate from the 2009 to 2019 cooling year is 12.8%. Now many air conditioning equipment under 7 horsepower choose twin-rotor compressors.

Characteristics of rotor compressors: Few parts and simple structure. Few wearing parts and reliable operation. There is no suction valve plate, the clearance volume is small, the gas transmission coefficient is relatively high, the processing precision requirements are relatively high, the sealing performance is poor, and the leakage loss is large.

The advantages of twin-rotor compressors are: good energy efficiency ratio at low frequencies, not as good as scroll compressors at high frequencies, slightly greater noise, vibration and wear than scroll compressors, shorter service life than scroll compressors, and difficult to achieve large displacement. The advantages of scroll compressors are: general energy efficiency ratio at low frequencies, better energy efficiency ratio than scroll compressors at high frequencies, small noise, vibration and wear, long service life, and can achieve large displacement. - Scroll refrigeration compressor

The scroll compressor is mainly composed of a movable disk (scroll rotor), a stationary disk (scroll stator), a bracket, a cross coupling ring, a back pressure chamber, and an eccentric shaft. It can be divided into two types: low-pressure chamber compression and high-pressure chamber.

Low-pressure chamber compressors are characterized by the entire casing being at a low temperature, and the inside of the casing cavity (except for the exhaust port and exhaust cavity) is at a low pressure; high-pressure chamber compressors are characterized by the entire casing being at a high temperature, and the inside of the casing cavity (except for the suction port and suction cavity) is at a high pressure.

Characteristics of scroll compressors: Stable operation, small vibration, quiet working environment, very few wearing parts, stable operation, low noise, long service life, and a high EER value. They are used in refrigeration, freezing and air conditioning systems. - Screw refrigeration compressor

The screw refrigeration compressor is mainly composed of a casing, rotors, bearings, shaft seals, balance pistons, energy regulating devices, etc. The screw refrigeration compressor has two screws with spiral tooth grooves meshing and rotating, causing changes in the volume between the teeth, thereby completing the processes of suction and compression. The cooling capacity can be adjusted steplessly between 10% and 100%. Screw refrigeration compressors are now widely used in refrigeration, freezing and HVAC equipment.

Characteristics of screw refrigeration compressors: The rotors and bearings have relatively high strength and wear resistance; the displacement is almost unaffected by the exhaust pressure; it maintains high efficiency within a wide operating range; stepless energy adjustment can be achieved and it is not sensitive to liquid inlet. Then, is the screw compressor afraid of liquid hammer? Many people answer that it is not afraid of liquid hammer. In fact, screw compressors are also afraid of liquid hammer. It's just that screw compressors are not so sensitive to a small amount of liquid return.

A large amount of liquid return will still cause compressor failures. This point needs attention.

- Centrifugal refrigeration compressor

The centrifugal refrigeration compressor belongs to a speed-type compressor and is a kind of impeller rotating machinery.

It does work on the gas by means of a high-speed rotating impeller to increase the pressure of the gas. Refrigeration compressors with a single-unit capacity of more than 1200 kW almost all use centrifugal refrigeration compressors. Generally, centrifugal compressors are used in large and extra-large air conditioning equipment.

Characteristics of centrifugal refrigeration compression: Good dynamic balance characteristics, small vibration; few wearing parts and long continuous operation cycle; easy to achieve multi-stage compression and throttling to achieve various evaporation temperatures; can be adjusted steplessly economically; when the refrigeration capacity is small, the efficiency is low; prone to surge.

Related Articles

- Introduction to Basic Types of Cold Storage

- Cleaning Methods for Different Types of Condensers in Refrigeration Devices

- Types and Temperature Requirements of Seed Cold Storages

- Introduction to Types of Condensers in Cold Storage

- What are the important significances of a warm environment for various types of food?

- Four types of flammable and explosive refrigerants

- The characteristics and uses of 26 types of air conditioning refrigerants

- Have You Encountered the Three Common Problems of Refrigeration Compressors?

- How to Calculate Refrigeration Load? And What Are the Issues?

- What to Do if the Compressor of a Frozen and Refrigerated Display Cabinet Runs but the Refrigeration Effect Is Poor?

- Instructions for Welding and Drainage in the Installation of Refrigeration Equipment Pipelines

- Common Pressure Valves and Protection Devices in Refrigeration Units

- Precautions for Using Rotary Refrigeration Compressors

- What Misconceptions Should Be Avoided in Low - temperature Refrigeration System Repairs

- Essential for Maintenance! Parameters and Phenomena of Normal Operation of Refrigeration and Heating Systems

- Composition and Common Faults of Screw Refrigeration Compressors

- How to Read the High - and Low - Pressure Gauges of Refrigeration Air - conditioners?

- What is Cascade Refrigeration?