Analysis of Maintenance and Overhaul of Cold Storage Evaporators

2025-04-07

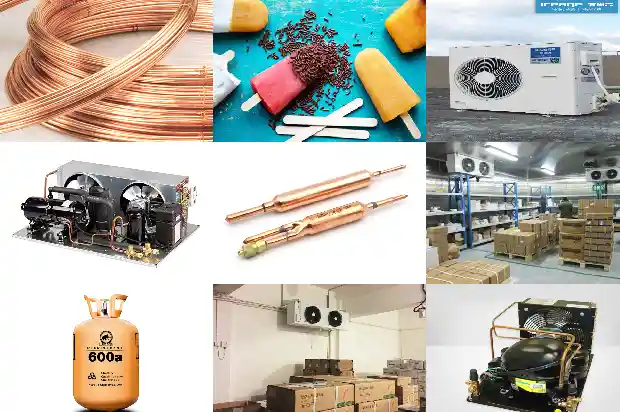

As one of the four major components of cold storage equipment, the cold storage evaporator may develop various malfunctions as the operation time of the cold storage project increases. These malfunctions can prevent the cold storage from operating efficiently. In such cases, we need to repair and maintain the cold storage evaporator. The following introduces the causes of malfunctions in the cold storage evaporator, as well as effective methods for its inspection, repair, and maintenance.

With the increase in operation time, a large amount of refrigeration lubricating oil may accumulate on the inner wall of the pipes of the low - temperature cold storage evaporator, especially when the cold storage design or installation is unreasonable. Excessive oil accumulation on the inner wall of the cold storage evaporator pipes can cause a significant decline in the heat transfer coefficient of the evaporator, directly affecting the refrigeration effect of the cold storage, increasing the power consumption during cold storage operation, and seriously affecting the service life of the cold storage compressor. After this type of malfunction occurs, not only should the accumulated oil on the inner wall of the pipes be removed in a timely manner, but also a corresponding technical rectification plan should be formulated according to the actual situation of the cold storage project, so as to solve the root cause once and avoid the recurrence of the malfunction.

The second common malfunction of the cold storage evaporator is blockage.

During operation, the cold storage evaporator may also experience malfunctions such as corrosion, impact leakage, and flange joint leakage.

Related Articles

- A Brief Analysis of the Causes of Condenser Surface Temperature Rise

- Analysis of Selection Techniques for Thermal Insulation Materials in Seafood Freezer Construction

- The Most Comprehensive Analysis of Water Pump Failures in History, Summarized by an Expert!

- Operation: Analysis of 20 Major Faults of Screw Compressors!

- Analysis and Solutions for Common Faults in Refrigeration Systems

- Analysis of Common Malfunctions and Treatment Methods of Cold Storage Equipment

- Analysis of Causes for Exhaust Malfunctions of Screw - type Chiller Compressors

- Analysis of Classification, Differences, Advantages and Disadvantages of Cold Storage Refrigeration Compressors

- A Brief Analysis of Quick - Freezing Cold Storage Design

- Analysis of the Causes of Frost Formation at the Suction Port of the Refrigeration Compressor

- Analysis of Common Faults of Chillers

- Analysis by Experts: Why Does the Four-way Reversing Valve Fail?

- Analysis of the Main Functions and Components of Refrigeration Air Conditioners

- Brief Analysis of Commonly Used Automatic Control Devices in the Refrigeration System

- Analysis of Common Auxiliary Components in the Refrigeration System One by One

- A Detailed Analysis of the Nine Reasons for the Low Pressure in the Refrigeration System!

- Analysis of the Working Process and Principle of Hot Fluoride Defrosting for Air Coolers

- Advantages and Disadvantages of Air-cooled Multi-connected Units and Analysis of Their Components