Cleaning Methods for Refrigeration Equipment

2024-10-01

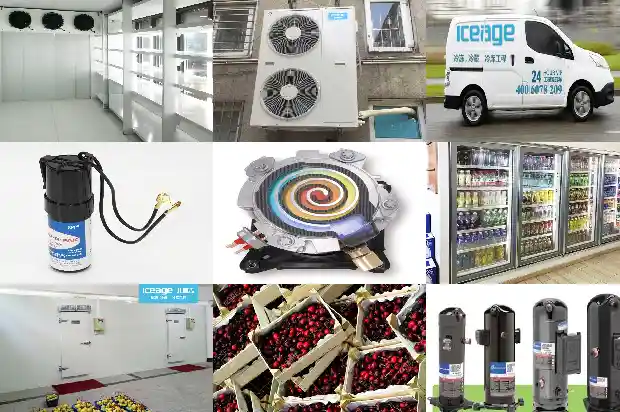

In daily life, refrigeration equipment is of great help to us. From small household refrigerators to large cold storage warehouses for low-temperature storage of fruits, vegetables and meat. The use of refrigeration equipment has brought great convenience to our lives and operations. However, as the number of stored items increases and the service time of cold storage warehouses lengthens, in order to better preserve and refrigerate and at the same time increase the service life of refrigeration equipment, we need to clean refrigeration equipment regularly.

In a well-designed and properly installed refrigeration equipment, the phenomenon of motor burnout due to damage to the built-in motor insulation layer is rare.

For refrigeration equipment with a damaged compressor due to motor burnout, a hasty cleaning cannot be done. Otherwise, the replaced built-in motor will be burned again due to the residues left in the equipment by the previous motor burnout.

To avoid the above situation, here are several cleaning steps for such equipment:

- Close the compressor stop valve and separate other parts of the equipment from the compressor. Remove the compressor without a stop valve and install a replacement compressor.

- Take some lubricating oil samples from the replacement compressor and place them in a glass. This can be used for comparison after the cleaning work is completed.

- Close the compressor stop valve and separate other parts of the equipment from the compressor. Remove the compressor without a stop valve and install a replacement compressor.

- Check all control and switching devices, such as expansion valves, solenoid valves, safety valves, bypass valves, etc. If necessary, clean or replace them. Remove or replace all drying filters. The filter elements or meshes must be completely cleaned or replaced. If the sight glass fails, it should also be replaced. Install an acid absorption drying filter in the suction pipeline and a large-capacity acid absorption drying filter in the liquid pipeline according to the output power of the equipment.

- Both the acid absorption drying filter in the suction pipeline and the large-capacity acid absorption drying filter in the liquid pipeline must be installed. The specifications of both are determined according to the capacity of the equipment.

- Use the compressor and keep the system in operation. The residual dirt precipitated from the system will increase the pressure loss of the drying filter. Therefore, the pressure drop of the drying filter should be checked at most every 4 hours to avoid measurement errors.

To avoid this error, checks should be made frequently. If the pressure drop exceeds the maximum value in Figures 31 to 33, replace the relevant drying filter.

- After 48 hours of system operation, check the smell and color of the lubricating oil. If possible, determine the acid content in it with an acid meter. If the lubricating oil has a burnt sour smell or the sight glass shows a high moisture content, the drying filter and lubricating oil should be replaced again. The system must be repeated to check as specified above again after running for another 48 hours. Such repeated operation and inspection are carried out until the lubricating oil is pure and odorless and the color is similar to the original oil sample taken in point 2 above.

- Replace the large-capacity drying filter on the liquid pipeline with a normal specification. The drying filter on the suction pipeline should be removed. If it is intended to be used continuously, reassemble it.

- To ensure smooth operation in the future, make another inspection two weeks after the cleaning work is completed and the equipment is restarted.

Related Articles

- Cleaning Procedures and Methods for Cooling Towers and Heat Exchangers

- Cleaning Methods for Different Types of Condensers in Refrigeration Devices

- Introduction to the Cleaning Processes and Methods of Heat Exchangers and Cooling Towers

- Introduction to Inspection and Handling Methods for Refrigerant Leak in Cold Storage

- Three Common Methods for Removing Water Scale from Water - cooled Condensers

- Reasons for Frost Formation in Cold Storage and Defrosting Methods

- Maintenance Methods for Small Modular Cold Storage Failures

- Common Cold - chain Storage Methods for Fruit and Vegetable Cold Storage

- Why Should Refrigerant Be Filled in Liquid Form? What Are the Filling Methods?

- For Computer Room Air Conditioners, Besides Air - cooled and Water - cooled, What Other Cooling Methods Are There?

- Maintenance Methods for Faults in Screw Refrigeration Air - conditioner Compressors

- Maintenance Methods for Refrigerant Leak in Air - conditioner Outdoor Unit

- Common Faults and Troubleshooting Methods of the Moving Mechanism of Piston Compressors

- Are you familiar with the detection and maintenance methods of air conditioner components?

- What are the precooling methods after the installation of cold storage?

- The Significance of Subcooling Degree in Refrigeration Systems and Methods for Achieving Subcooling

- Common Operating Faults and Treatment Methods of Centrifugal Compressors

- Methods for Mold Removal in Cold Storage