Common Knowledge of Refrigeration and Air Conditioning Systems!

2025-04-24

What is a secondary refrigerant, and what is its working principle?

It is a medium substance that transfers the refrigeration capacity of the refrigeration device to the medium to be cooled.

For example, the commonly used air conditioning chilled water is cooled in the evaporator and then transported over a long distance to cool the objects that need to be cooled. Currently, the commonly used secondary refrigerant is water, which can only be used under conditions above 0 °C. When the requirement is below 0 °C, brine is generally used, such as an aqueous solution of sodium chloride or calcium chloride, or an aqueous solution of organic compounds such as ethylene glycol and propylene glycol.

According to the purpose of use, how many types can air conditioners be divided into?

Comfort air conditioners: They require a suitable temperature and a comfortable environment, and there is no strict requirement for the adjustment accuracy of temperature and humidity. They are used in housing, offices, cinemas, shopping malls, gymnasiums, cars, ships, airplanes, etc.

Process air conditioners: They have a certain requirement for the adjustment accuracy of temperature, and also have a high requirement for the cleanliness of the air. They are used in electronic device production workshops, precision instrument production workshops, computer rooms, biological laboratories, etc.

Nominal refrigeration capacity:

The amount of heat removed from a space area or room by an air conditioner under nominal refrigeration conditions per unit time is called the nominal refrigeration capacity.

Nominal heating capacity:

The amount of heat released into a space area or room by an air conditioner under nominal heating conditions per unit time.

Energy efficiency ratio (EER-COOLING):

The size of the refrigeration capacity per unit of motor input power. It reflects the ratio of the refrigeration capacity to the refrigeration power during the refrigeration operation of the air conditioner, with the unit of W/W. The national standard stipulates that the standard value of the energy efficiency ratio for a 2500W air conditioner is 2.65; the standard value of the energy efficiency ratio for an air conditioner with a capacity from 2500W to 4500W is 2.70.

Performance parameter (COP-HEATING):

The COP value of the performance parameter of the refrigeration compressor, that is, the refrigeration capacity per unit of shaft power. Shaft power (the power consumption of the compressor) refers to the power transmitted from the motor to the compressor shaft, mainly including the power consumed directly for compressing air and the power consumed to overcome the frictional resistance of the moving mechanism.

Knowledge of compressors:

The compressor is the core of the entire air conditioning system and also the source of power for the system.

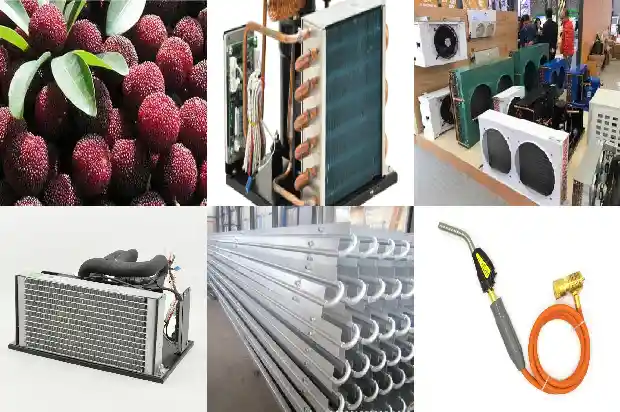

Knowledge of heat exchangers:

According to their different functions in air conditioners, heat exchangers can be divided into condensers and evaporators. Now, let's describe the classification and differences between condensers and evaporators.

Knowledge of condensers:

The function of the condenser is to cool the superheated refrigerant vapor with high temperature and high pressure discharged from the compressor into a liquid or a mixture of gas and liquid. The heat released by the refrigerant in the condenser is carried away by the cooling medium (water or air). According to the cooling medium and the cooling method, condensers can be divided into three types: water-cooled type, air-cooled type, and water and air mixed-cooled type.

Knowledge of evaporators:

The function of the evaporator is to use the fact that the low-temperature liquid refrigerant is easy to evaporate under low pressure, transform into vapor, and absorb the heat of the medium to be cooled to achieve the purpose of refrigeration.

Knowledge of throttling structures:

The throttling component is one of the four essential components of the refrigeration system. Its function is to throttle and reduce the pressure of the high-pressure liquid coming out of the condenser, so that the liquid refrigerant vaporizes and absorbs heat under low pressure (low temperature). Therefore, it is an important component that maintains the high pressure in the condenser and the low pressure in the evaporator.

Knowledge of gas-liquid separators:

In the evaporator, due to the evaporation of the liquid in the evaporator, the process of changing from liquid to gas, considering the change of the load, a part of the refrigerant may not be completely evaporated and will directly enter the compressor. Due to the incompressibility of the liquid, before entering the compressor, it must first pass through the gas-liquid separator to ensure that all the substances entering the compressor are gases and ensure the normal operation of the compressor.

Points to note when using a gas-liquid separator:

★ As close to the compressor as possible;

★ In the reversing system, the gas-liquid separator should be installed between the reversing valve and the compressor;

★ Correctly install the inlet (from the evaporator) and the outlet (to the suction port of the compressor);

★ Must be installed upwards;

★ The interface of a gas-liquid separator of an appropriate size is not necessarily the same as the suction port of the compressor.

Knowledge of receivers:

The high-pressure receiver (also known as the liquid receiver) in the refrigeration system is installed between the condenser and the expansion valve. Its functions can be summarized in the following aspects:

★ Store the condensate from the condenser

★ Adapt to the demand for the supply volume due to the load variation of the evaporator

★ Act as a liquid seal between the high-pressure side and the low-pressure side of the system. There are various forms of receivers, including one-way and two-way types; those with one outlet and those with two outlets; vertical and horizontal types.

Knowledge of oil-gas separators:

The oil-gas separator is installed between the compressor and the condenser. Its working principle is as follows: The exhaust gas of the compressor is a mixed gas of Freon and lubricating oil. By reducing the speed in the larger cavity of the oil separator, the mist-like oil will gather on the impact surface. When larger oil droplets are formed, they will flow to the bottom of the oil separator and return to the compressor through the oil return device.

Knowledge of drying filters:

The function of the filter is: In order to prevent water from being contained in the refrigerant or water from entering the system due to unavoidable elements, when the high-temperature liquid coming out of the condenser enters the expansion valve, the temperature of the liquid will drop significantly, generally below zero degrees. At this time, if there is water in the system, since the cross-section through which the expansion valve passes is very small, the phenomenon of ice blockage is likely to occur, affecting the normal operation of the system.

Knowledge of four-way reversing valves:

The four-way reversing valve is suitable for heat pump air conditioning systems such as central air conditioners and unitary air conditioners. It is used to switch the flow path of the refrigeration medium to achieve the purposes of refrigeration and heating.

Knowledge of water pumps:

The water pump is a tool used to accelerate the flow of water to enhance the heat exchange effect of water in the heat exchanger.

Pressure controller:

The pressure controller is used for pressure control and pressure protection. The unit is equipped with a low-pressure controller and a high-pressure controller, which are used to control the working range of the system pressure. When the system pressure reaches the set value, the switch automatically cuts off (or connects) the circuit.

Differential pressure controller:

The differential pressure controller is used for the control of the pressure difference. When the pressure difference reaches the set value, the switch automatically cuts off (or connects) the circuit.

Temperature controller:

The temperature controller is used for the control or protection of the unit. When the temperature reaches the set value, the switch automatically cuts off (or connects) the circuit. In our products, temperature control is commonly used, and the temperature of the water tank is used to control the start and stop of the unit. There are also some situations like anti-freezing that require the use of a temperature controller.

Liquid sight glass:

The liquid sight glass is used to indicate:

It is a medium substance that transfers the refrigeration capacity of the refrigeration device to the medium to be cooled.

For example, the commonly used air conditioning chilled water is cooled in the evaporator and then transported over a long distance to cool the objects that need to be cooled. Currently, the commonly used secondary refrigerant is water, which can only be used under conditions above 0 °C. When the requirement is below 0 °C, brine is generally used, such as an aqueous solution of sodium chloride or calcium chloride, or an aqueous solution of organic compounds such as ethylene glycol and propylene glycol.

According to the purpose of use, how many types can air conditioners be divided into?

Comfort air conditioners: They require a suitable temperature and a comfortable environment, and there is no strict requirement for the adjustment accuracy of temperature and humidity. They are used in housing, offices, cinemas, shopping malls, gymnasiums, cars, ships, airplanes, etc.

Process air conditioners: They have a certain requirement for the adjustment accuracy of temperature, and also have a high requirement for the cleanliness of the air. They are used in electronic device production workshops, precision instrument production workshops, computer rooms, biological laboratories, etc.

Nominal refrigeration capacity:

The amount of heat removed from a space area or room by an air conditioner under nominal refrigeration conditions per unit time is called the nominal refrigeration capacity.

Nominal heating capacity:

The amount of heat released into a space area or room by an air conditioner under nominal heating conditions per unit time.

Energy efficiency ratio (EER-COOLING):

The size of the refrigeration capacity per unit of motor input power. It reflects the ratio of the refrigeration capacity to the refrigeration power during the refrigeration operation of the air conditioner, with the unit of W/W. The national standard stipulates that the standard value of the energy efficiency ratio for a 2500W air conditioner is 2.65; the standard value of the energy efficiency ratio for an air conditioner with a capacity from 2500W to 4500W is 2.70.

Performance parameter (COP-HEATING):

The COP value of the performance parameter of the refrigeration compressor, that is, the refrigeration capacity per unit of shaft power. Shaft power (the power consumption of the compressor) refers to the power transmitted from the motor to the compressor shaft, mainly including the power consumed directly for compressing air and the power consumed to overcome the frictional resistance of the moving mechanism.

Knowledge of compressors:

The compressor is the core of the entire air conditioning system and also the source of power for the system.

Knowledge of heat exchangers:

According to their different functions in air conditioners, heat exchangers can be divided into condensers and evaporators. Now, let's describe the classification and differences between condensers and evaporators.

Knowledge of condensers:

The function of the condenser is to cool the superheated refrigerant vapor with high temperature and high pressure discharged from the compressor into a liquid or a mixture of gas and liquid. The heat released by the refrigerant in the condenser is carried away by the cooling medium (water or air). According to the cooling medium and the cooling method, condensers can be divided into three types: water-cooled type, air-cooled type, and water and air mixed-cooled type.

Knowledge of evaporators:

The function of the evaporator is to use the fact that the low-temperature liquid refrigerant is easy to evaporate under low pressure, transform into vapor, and absorb the heat of the medium to be cooled to achieve the purpose of refrigeration.

Knowledge of throttling structures:

The throttling component is one of the four essential components of the refrigeration system. Its function is to throttle and reduce the pressure of the high-pressure liquid coming out of the condenser, so that the liquid refrigerant vaporizes and absorbs heat under low pressure (low temperature). Therefore, it is an important component that maintains the high pressure in the condenser and the low pressure in the evaporator.

Knowledge of gas-liquid separators:

In the evaporator, due to the evaporation of the liquid in the evaporator, the process of changing from liquid to gas, considering the change of the load, a part of the refrigerant may not be completely evaporated and will directly enter the compressor. Due to the incompressibility of the liquid, before entering the compressor, it must first pass through the gas-liquid separator to ensure that all the substances entering the compressor are gases and ensure the normal operation of the compressor.

Points to note when using a gas-liquid separator:

★ As close to the compressor as possible;

★ In the reversing system, the gas-liquid separator should be installed between the reversing valve and the compressor;

★ Correctly install the inlet (from the evaporator) and the outlet (to the suction port of the compressor);

★ Must be installed upwards;

★ The interface of a gas-liquid separator of an appropriate size is not necessarily the same as the suction port of the compressor.

Knowledge of receivers:

The high-pressure receiver (also known as the liquid receiver) in the refrigeration system is installed between the condenser and the expansion valve. Its functions can be summarized in the following aspects:

★ Store the condensate from the condenser

★ Adapt to the demand for the supply volume due to the load variation of the evaporator

★ Act as a liquid seal between the high-pressure side and the low-pressure side of the system. There are various forms of receivers, including one-way and two-way types; those with one outlet and those with two outlets; vertical and horizontal types.

Knowledge of oil-gas separators:

The oil-gas separator is installed between the compressor and the condenser. Its working principle is as follows: The exhaust gas of the compressor is a mixed gas of Freon and lubricating oil. By reducing the speed in the larger cavity of the oil separator, the mist-like oil will gather on the impact surface. When larger oil droplets are formed, they will flow to the bottom of the oil separator and return to the compressor through the oil return device.

Knowledge of drying filters:

The function of the filter is: In order to prevent water from being contained in the refrigerant or water from entering the system due to unavoidable elements, when the high-temperature liquid coming out of the condenser enters the expansion valve, the temperature of the liquid will drop significantly, generally below zero degrees. At this time, if there is water in the system, since the cross-section through which the expansion valve passes is very small, the phenomenon of ice blockage is likely to occur, affecting the normal operation of the system.

Knowledge of four-way reversing valves:

The four-way reversing valve is suitable for heat pump air conditioning systems such as central air conditioners and unitary air conditioners. It is used to switch the flow path of the refrigeration medium to achieve the purposes of refrigeration and heating.

Knowledge of water pumps:

The water pump is a tool used to accelerate the flow of water to enhance the heat exchange effect of water in the heat exchanger.

Pressure controller:

The pressure controller is used for pressure control and pressure protection. The unit is equipped with a low-pressure controller and a high-pressure controller, which are used to control the working range of the system pressure. When the system pressure reaches the set value, the switch automatically cuts off (or connects) the circuit.

Differential pressure controller:

The differential pressure controller is used for the control of the pressure difference. When the pressure difference reaches the set value, the switch automatically cuts off (or connects) the circuit.

Temperature controller:

The temperature controller is used for the control or protection of the unit. When the temperature reaches the set value, the switch automatically cuts off (or connects) the circuit. In our products, temperature control is commonly used, and the temperature of the water tank is used to control the start and stop of the unit. There are also some situations like anti-freezing that require the use of a temperature controller.

Liquid sight glass:

The liquid sight glass is used to indicate:

- The condition of the refrigerant in the liquid pipeline of the refrigeration device;

- The water content in the refrigerant;

- The flow condition of the lubricating oil from the oil separator in the oil return pipeline. Some liquid sight glasses are equipped with an indicator, which indicates the water content in the refrigerant by changing its color. (Green indicates dryness, and yellow indicates humidity)

The functions of the expansion tank: - Due to the volume change of water caused by temperature changes, the expansion tank is used to store this part of the expanded water;

- It plays a role in stabilizing and maintaining the pressure of the system;

- It can compensate part of the water for the system.

The function of the cooling tower:

The function of the cooling tower is to exchange heat between the cooling water carrying heat and the air in the tower, so that the heat is transferred to the air and dissipated into the atmosphere. One of the heat exchange methods between water and air in the cooling tower is that the air flowing over the water surface is in direct contact with the water, and through contact heat transfer and evaporative heat dissipation, the heat in the water is transferred to the air. The cooling tower using this method is called a wet cooling tower. The wet cooling tower has high heat exchange efficiency, and the limiting temperature for water cooling is the wet bulb temperature of the air. However, water is lost due to evaporation; evaporation also increases the salinity of the circulating cooling water. In order to stabilize the water quality, a part of the water with a higher salinity must be discharged; the wind will also cause the loss of water due to dispersion. Sufficient new water must be continuously replenished.

Therefore, a wet cooling tower requires a water source for supplying water. In water-scarce areas, in the case of difficulties in replenishing water, only a dry cooling tower can be used. The heat exchange between air and water in a dry cooling tower is carried out through heat transfer on the surface of the radiator composed of metal pipes, and the heat of the water in the pipes is transferred to the air flowing outside the radiator. The heat exchange efficiency of a dry cooling tower is lower than that of a wet cooling tower, and the limiting temperature for cooling is the dry bulb temperature of the air.

The one-time investment in these devices is large, and the energy consumption of the fans is very high. The process of cooling water in the cooling tower belongs to the process of heat and mass transfer. The cooled water is distributed to the internal packing of the cooling tower by nozzles, water distributors, or water distribution trays, greatly increasing the contact area between water and air. The air is circulated by fans, forced air flow, natural wind, or the induced effect of spraying.

Related Articles

- Do You Know These Commonly Used Cold Storage Knowledge?

- What Knowledge Points Should Users Know about the Safety Valve in the Refrigeration System?

- Do You Know These Basic Refrigeration Knowledge?

- Basic Knowledge of Valve - type Components in Refrigeration Systems (Technical Sharing)

- Do You Know All These Knowledges about the Absorption Unit of the Lithium Bromide Refrigeration Machine?

- HVAC - Comprehensive Knowledge You Must Know about Cooling Towers

- The Most Comprehensive Popular Science of Refrigeration and HVAC Basic Knowledge Across the Network!

- Understand These Refrigeration Knowledge to Boost Your Style!

- Basic Knowledge of Cold Storage Maintenance

- The Most Comprehensive Knowledge of Refrigeration Oil, Definitely Useful in the Future!

- Popularize Refrigeration Knowledge You've Never Noticed, Which Is Actually Very Crucial

- Practical Knowledge on Freeze Protection of Air - conditioning Equipment

- Basic Knowledge of Valve - type Components in Refrigeration Systems (Technical Sharing)

- Basic Knowledge of Cooling Towers

- Knowledge, Installation and Maintenance of Cold Storage Systems

- Obscure Knowledge of Static Pressure, Dynamic Pressure, Latent Heat and Sensible Heat in the HVAC Industry

- Fin Spacing Design of Cooler and Several Knowledge Points of Defrosting in Cold Storage

- These have the most direct relationship with the refrigeration effect