Common Problems in the Installation and Maintenance of Cold Storage Systems

2025-04-11

- The refrigeration compressor unit is not installed with vibration damping, or the vibration damping effect is poor. According to the installation specifications, the overall vibration damping device of the unit should be installed. If the vibration damping is not standardized or there are no vibration damping measures, the machine will vibrate violently, which is likely to cause the pipeline to crack due to vibration, damage the equipment, and even damage the machine room.

- There is no or a lack of oil return bends in the refrigerant pipeline. When the pipeline transporting the refrigerant turns upward from the horizontal direction, it must be made into a small bend that first drops downward and then goes upward, that is, a U-shaped bend. Only in this way is the pipeline qualified when it goes upward again. It cannot be directly made into a 90-degree turn and go upward.

Otherwise, the oil in the system cannot return to the compressor well, but will deposit in large quantities in the air cooler, preventing the air cooler and the entire system from functioning properly, and even damaging the air cooler and the unit equipment.

- The connection of the refrigerant pipeline is unbalanced. When the unit pipeline is connected to a group of multiple compressors, to ensure that the oil return is evenly distributed to each compressor, the interface of the main pipeline must be set in the middle position among multiple compressor heads, and then some branch pipelines should be set on both sides respectively, allowing the oil return to flow evenly into the branch pipes of multiple compressors.

Moreover, valves should be installed on each branch pipe to adjust the amount of oil return. If not, but multiple downward branch pipes are successively led out from different parts of the main pipeline and connected to multiple compressors, the oil return will be unbalanced. The oil return of the first compressor is always the fullest, and the oil return of the subsequent compressors gradually decreases in turn. In this way, it is possible for the first compressor to have operating failures, such as huge vibrations, excessive oil pressure, and overheating of the unit, resulting in accidents such as the compressor cylinder being damaged or seized, and damaging the equipment. - The pipeline is not insulated. Without insulation materials, the cold pipeline will frost under the ambient temperature, which will affect the refrigeration effect, increase the load of the unit, and then cause the unit to operate with excessive strength, reducing the service life of the unit.

- Regularly check various technical indicators and adjust them in a timely manner. Check and adjust in a timely manner the operating temperature and pressure of the system, as well as the quantities of lubricating oil and refrigerant. The system should have an automatic control and compressor alarm device. Once there is a problem, it will send out an alarm prompt or automatically shut down protectively, and the compressor will stop.

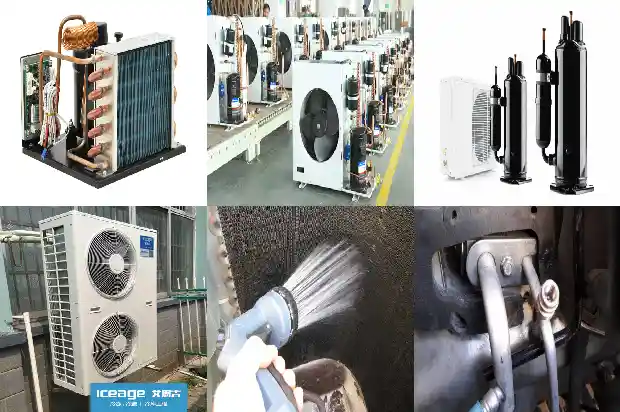

- Maintenance of the unit. Replace the lubricating oil and filter regularly. Supplement the refrigerant as needed. The condenser should be cleaned at any time to keep it clean to avoid the influence of dust, sediment, flying catkins, and other debris on the refrigeration effect.

Some people believe that as long as there are no impurities in the lubricating oil, it can continue to be used, and even if it has been used for more than two years, there is no need to replace it. This is obviously wrong. The lubricating oil has been operating at a high temperature in the system for a long time, and its performance may have changed, failing to play its due role in lubrication, etc. If it is not replaced, it will cause the operating temperature of the machine to rise and may even damage the machine.

The filter should also be replaced regularly. We know that general machines have "three filters" and they all need to be replaced regularly. The refrigeration compressor system may not have "three filters" but only one oil filter, which should also be replaced regularly. If it is believed that the filter is made of metal and there is no need to replace it as long as it is not damaged, this view is groundless and untenable. - Installation environment and maintenance issues of the air cooler. The position and environment of the air cooler inside the cold storage will affect its operation. Generally, the air cooler near the cold storage door is prone to condensation and frosting. Because of its position near the door, when the door is opened, the hot air outside enters. When it encounters the air cooler, it condenses and frosts, and may even freeze. Although the air cooler can automatically heat and defrost regularly, if the door is opened too frequently and for too long, and the hot air enters for a long time and in a large quantity, the defrosting effect of the air cooler will not be good. Because the defrosting time of the air cooler cannot be too long, otherwise the refrigeration time will be relatively shortened, the refrigeration effect will be poor, and the temperature in the storage cannot be guaranteed.

In some cold storages, due to too many doors, high frequency and long opening time of the doors, lack of insulation measures at the door, and no partition wall inside the door, the cold and hot air inside and outside are directly exchanged, and the air cooler near the door will inevitably encounter serious frosting problems.

- The drainage problem of the water melted during the defrosting of the air cooler. This problem is related to the severity of frosting. Due to serious frosting of the air cooler, a large amount of condensed water will inevitably be generated. If the water receiving tray of the air cooler cannot bear it and the drainage is not smooth, the water will leak and flow onto the ground inside the storage. If there are goods stored below, the goods will be soaked. In this case, a water receiving tray can be added, and a thicker diversion pipe can be installed to drain the condensed water.

Some air coolers have the problem of water being blown out from the fan and spraying onto the goods stored in the storage.

This is also a frosting problem of the air cooler in the hot and cold exchange environment. It is mainly the condensed water generated on the fan blades in the hot environment, rather than a problem of the defrosting effect of the air cooler itself. To solve the problem of condensed water in the air cooler, the environment must be improved. If there is a partition wall inside the storage door in the design, the partition wall should not be removed. If the partition wall is removed for the convenience of loading and unloading goods, the environment of the air cooler will change, the refrigeration effect cannot be achieved, the defrosting effect will also be poor, and even the air cooler will frequently malfunction and the equipment will have problems.

- Problems of the fan motor of the condenser and the electric heating tube of the air cooler. These are vulnerable components. The fan motor that operates for a long time in a high-temperature environment may malfunction and be damaged. If it is very important to ensure the temperature of the cold storage, some vulnerable parts should be ordered for timely maintenance. The electric heating tube of the air cooler also requires spare parts for better safety.

- Problems of the temperature of the cold storage and the cold storage door. For a cold storage, factors such as its area, the quantity of goods stored, the number of doors, the opening and closing time and frequency of the doors, the frequency of goods entering and leaving, and the cargo throughput all affect the temperature inside the storage.

- Fire safety issues of the cold storage. The temperature in a cold storage is generally around minus 20 degrees Celsius. Due to the low ambient temperature, it is not suitable to install a fire sprinkler system. Therefore, more attention should be paid to fire prevention in the cold storage. Although the ambient temperature in the cold storage is low, if a fire occurs and there are combustibles in the storage, especially the goods are often packed in cartons and wooden boxes, they are very easy to burn. Therefore, the fire hazard in the cold storage is also very high, and fireworks are strictly prohibited in the cold storage. At the same time, the air cooler, its wire box, power cord, and electric heating tube should also be regularly inspected to eliminate potential electrical fire hazards.

- The problem of the ambient temperature of the condenser. The condenser is generally installed on the roof of the building outdoors. In the environment with high temperatures in summer, the temperature of the condenser itself is very high, increasing the operating pressure of the unit. If there are many high-temperature days, a canopy can be built on the roof of the condenser to block the sunlight, reducing the temperature of the condenser, so as to achieve the purpose of reducing the pressure on the machine, protecting the unit equipment, and ensuring the temperature of the cold storage. Of course, if the capacity of the unit is sufficient to ensure the temperature of the storage, the canopy may not be built.

Related Articles

- An Experienced Craftsman Summarizes the Common Problems of Cold Storage Equipment, It's Really Comprehensive!

- Eight Quality Problems in HVAC Installation Construction and Corrective Measures

- What Should Be Done When These Problems Occur in the Semi-hermetic Piston Compressor of the Cold Storage?

- Common Problems in After-sales Maintenance of Refrigeration Units

- How to Solve Practical Problems of Air - conditioner Leakage, Noise and Refrigerant Leakage?

- Several Common Problems in the Operation of the Refrigeration System

- HVAC - Solving the 5 Common Problems in the Refrigeration System

- Five Common Problems in the Refrigeration System~~ Solve Them One by One!

- Have You Encountered the Three Common Problems of Refrigeration Compressors?

- Matters Concerning the Installation of Parallel Units [Part 2]

- Commissioning of the Refrigeration System after Installation and Major Overhaul: Very Detailed!

- Introduction to the Installation Process of Marine Prefabricated Cold Storage

- Simple and Understandable Installation Method of Vibration - isolation Tubes for Refrigeration Compressors

- How to Operate the Cold - storage Distribution Box during Cold - storage Installation

- How Important Is the Installation Environment of Refrigeration Units? Just Do These 4 Points!

- Installation Precautions for the Source Components of Automatic Instruments in Refrigeration Units

- Precautions for the Installation of Automatic Instruments in Refrigeration Devices (Part One)

- Installation and Welding of Precision Air Conditioning Systems