How to accurately choose water-cooled and air-cooled chillers?

2024-12-02

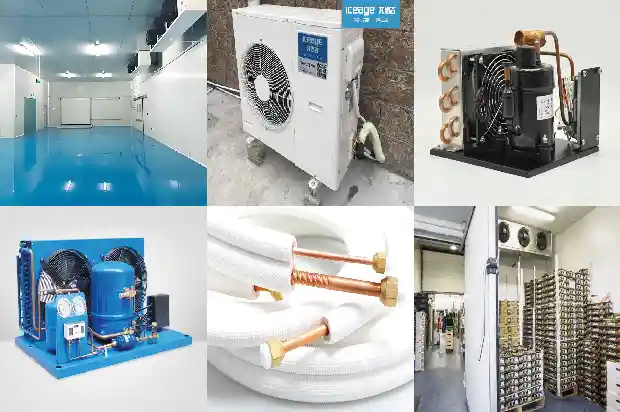

In industrial production, chillers are essential, such as for cooling equipment and controlling the temperature of materials. There are many ways of cooling, and chillers can be divided into two types according to their types: air-cooled and water-cooled.

The air-cooled chiller uses a shell-and-tube evaporator to conduct heat exchange between water and the refrigerant. The refrigerant system absorbs the heat load in the water. After the cooling water produces cold water, the heat is carried to the finned condenser through the action of the compressor and then dissipated into the external air (air cooling) through the cooling fan.

The water-cooled chiller uses a shell evaporator to conduct heat exchange between water and the refrigerant.

In fact, both types of chillers use refrigerant circulation for refrigeration, and usually, they can be mutually compatible.

For the above two types of chillers, the main comparisons are as follows:

- Performance comparison:

The heat transfer temperature difference of the condenser of the water-cooled unit is generally 4 - 8 °C, while that of the air-cooled unit is generally 8 - 15 °C. Under the same outdoor ambient temperature, the temperature of the cooling circulating water is lower than that of the outdoor air. Therefore, the condensing temperature for the normal operation of the air-cooled unit is much higher than that of the water-cooled unit, resulting in the power consumption of the air-cooled unit being greater than that of the water-cooled unit under the same refrigeration capacity. - Comparison of initial equipment investment:

Since the heat exchange efficiency of water is much greater than that of air, compared with the water-cooled condenser with the same heat exchange capacity, the air-cooled condenser has a larger equipment volume, uses more materials, and has a higher manufacturing cost. Since the nominal power of the air-cooled unit is greater than that of the water-cooled unit, the costs for increasing the power capacity and electrical control equipment are also higher. - Comparison of equipment in the machine room:

The air-cooled chiller is an outdoor machine and can be placed on the roof of a building or on the outdoor ground. Its chilled water circulating pump can also be placed together with the unit without occupying the machine room. For the water-cooled chiller, a machine room should be provided to ensure the normal operation and service life of the equipment, including the chiller, the chilled water circulating pump, and the cooling water circulating pump, and cooling tower equipment should be set up on the roof of the building or on the outdoor ground. It can be seen that when a building cannot provide a machine room, choosing an air-cooled chiller should be a more feasible option. - Comparison of operating costs:

Since the water-cooled unit operates at a lower condensing temperature, it has high refrigeration efficiency and low power consumption during unit operation. Generally speaking, compared with the air-cooled unit with the same refrigeration capacity, the total power consumption (including the cooling pump and the cooling tower fan) of the water-cooled chiller is only 70% of that of the air-cooled unit. - Maintenance comparison:

The shell-and-tube condenser used in the water-cooled unit has a relatively small impact on the heat exchange efficiency within a certain range of dirt accumulation. Therefore, the decline in unit performance due to dirt generation is relatively small, the cleaning cycle is long, and the relative maintenance cost is low. Moreover, the heat exchange efficiency of the finned condenser used in the air-cooled unit is greatly affected by dirt accumulation. A dust filter must be installed in front of the heat dissipation finned tubes, and it needs to be cleaned frequently. Since the air-cooled unit operates under high pressure and is generally installed outdoors with a relatively poor operating environment, it is inferior to the water-cooled unit in terms of maintenance and reliability.

Due to different functional compositions, different operating conditions of air-cooled and water-cooled units are also created. Generally, laboratories use air-cooled chillers more often, while in large-scale industrial production, water-cooled chillers are used more frequently.

Related Articles

- Basic Faults and Preventive Maintenance of Water - cooled Units

- Three Common Methods for Removing Water Scale from Water - cooled Condensers

- What Are the Differences Between Chillers and General Water - cooled Equipment?

- Selection of Bypass Control Valves for Air - conditioning Water Systems

- Operation of Screw - type Water - cooled Chiller Units

- Characteristics and Differences among Water System, Air System and Refrigerant System

- Accident Handling and Precautions for Circulating Water Pumps

- Startup, Shutdown and Accident Handling of Jet Water Pump

- How to Select and Use Water Pumps for Air - conditioning Systems?

- How to Choose Between Water-cooled and Air-cooled Cold Storage?

- Introduction to Various Water Tanks in Air - conditioning Systems

- For Computer Room Air Conditioners, Besides Air - cooled and Water - cooled, What Other Cooling Methods Are There?

- Refrigeration System Failures: Handling System Blockages and Water Infiltration

- Both are dual - connected systems. How to choose between air - fluorine - ground - water and air - water - ground - water systems after all?

- Precautions for the Installation and Use of Water Flow Switches

- Water Flow Control Technology for Small Air-cooled Hot and Cold Water Units

- 4 Points on Causes of Water Leakage in Closed Cooling Towers

- Water-cooled Screw Chiller: Operation and Maintenance