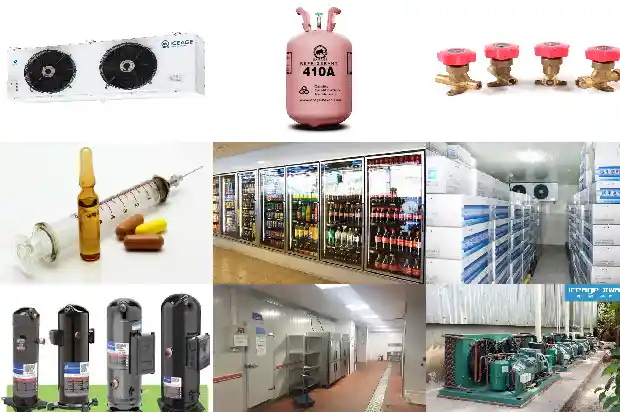

How to Identify Installation Materials for Refrigeration Equipment

2025-01-01

The commonly used installation materials for refrigeration and air - conditioning installations mainly include: refrigerant copper pipes, insulation cotton, condensate water pipes, and branch fittings. So, how can we distinguish the quality of these refrigeration materials?

I. Refrigerant Pipes

- Check the color: Currently, the best refrigerant copper pipes are purple copper pipes. Their purity is above 99% and they are called pure copper, showing a rose - red color. Other copper pipes are mostly alloy copper pipes, such as brass pipes, which are synthesized with a copper - zinc ratio of 7:3 and show a yellow color.

- Touch by hand: The inner and outer walls of high - quality refrigerant copper pipes are smooth and clean, without sand holes, oxidation, cracks and other defects.

- Bend the copper pipe: High - quality copper pipes have no creases and do not deform after bending; while inferior copper pipes are prone to creases and are easily deformed by extrusion after bending.

- Copper pipe process: Currently, the production of copper pipes mainly includes extrusion - type process copper pipes and drawn - type copper pipes. The extrusion - type ones have a thicker and more uniform wall thickness, while the wall thickness of the drawn - type ones is likely to be non - uniform. The new refrigerant R410A has a high operating pressure, and the thin - walled parts of the drawn - type copper pipes are prone to bursting.

II. Condensate Water Pipes

- Check the surface: Check the smoothness and whiteness of the water pipe surface. For good condensate water pipes, the inner and outer colors are the same, presenting a beige color, and the surface has an oily sheen. If the color is overly white, there may be too much calcium powder, and if it is yellowish, the PVC material may be of poor quality, prone to oxidation and with poor weather resistance.

- Measure the wall thickness: The wall thickness of a good condensate water pipe should be uniform and the wall should be smooth. Thicker walls are better.

- Sampling test: Pipes that are abnormally white and bright but easily broken when dropped are generally high - calcium products with added calcium powder. Take a sample and step on the edge of the pipe with your foot to see if it easily cracks.

III. Insulation Cotton

The national standard GB8624 - 97 classifies the combustion performance of materials as follows: Class A non - combustible, Class B1 flame - retardant, Class B2 combustible, and Class B3 highly flammable. Class A is the highest standard. Class B1 materials ignite when exposed to fire and self - extinguish when the fire source is removed. Class B2 materials ignite when exposed to fire and continue to burn after the fire source is removed.

- Check the appearance: The smaller and finer the foaming pores of the insulation cotton are, the better the anti - vibration, heat - insulation and heat - preservation effects will be.

- Measure the wall thickness: For the same grade and the same pre - installed copper pipe/water pipe diameter, the thicker the insulation wall thickness, the better the heat - preservation effect. And there are corresponding national standards for the thickness of insulation cotton for each pipe diameter.

- Extrusion test: Squeeze the insulation tightly by hand. If it is easily deformed after extrusion, it is generally inferior insulation, while if it does not deform after extrusion, it is generally high - quality insulation.

IV. Branch Fittings

- Check the appearance: High - quality branch fittings have a bright color, uniform and firm welding, and the inner and outer walls of the pipe are clean, without impurities and dirt. Poor - quality branch fittings are prone to weld separation, have impurities and are easy to oxidize.

- Measure the wall thickness: The thickness of the copper pipe used for the branch pipe should be determined according to the size of the diameter. The larger the diameter, the thicker the copper pipe should be. Generally, for a diameter of 22.3 and below, a 1mm - thick copper pipe is sufficient. For 31.8 and below, a 1.3mm copper pipe is used, and for 35 and above, a 1.5mm copper pipe is preferably used. Using a copper pipe of the appropriate thickness can ensure the quality to the greatest extent. Like copper pipes, branch fittings should preferably be made of purple copper, especially the branch fittings made of special purple copper pipes for R410A.

Related Articles

- Instructions for Welding and Drainage in the Installation of Refrigeration Equipment Pipelines

- What is the Correct Operation Method of the Distribution Box during Cold Storage Installation?

- What Issues Should Be Noted in Cold Storage Installation and Construction?

- What Special Requirements are There for the Installation of Tea Cold Storage?

- Operating Principle and Standard Installation Steps of Multi - split Systems in Refrigerant Air - conditioning Systems

- How to Identify the Quality of Refrigeration Equipment Installation Materials?

- Knowledge, Installation and Maintenance of Cold Storage Systems

- Precautions for the Installation and Use of Water Flow Switches

- What safety measures should be paid attention to during the installation of cold storage?

- What are the precooling methods after the installation of cold storage?

- Selection and Installation of Thermal Expansion Valves

- Return Bend Setup and Installation Technical Requirements

- Daily Maintenance Training for Users after Installation of Small and Medium-Sized Cold Storages

- Parallel Installation and Precautions for Scroll Compressors

- How to Select the Configuration for Cold Storage Installation?

- What inspections are required for central air conditioning installation?

- Introduction to Five Classification Functions of Cold Storage Installation for Refrigeration

- Installation and Oil Return Precautions for Refrigeration Equipment Pipelines