HVAC - Concise Explanation of Refrigeration Principles

2025-03-02

I. Classification of Air-Cooled and Water-Cooled Units:

Classified according to the form of the heat exchanger of the refrigeration equipment:

Classified according to the form of the heat exchanger of the refrigeration equipment:

- Air-cooled air-cooled chiller unit (abbreviated as: air-cooled or air-cooled unit);

- Air-cooled water chiller unit (abbreviated as: air-cooled water chiller unit);

- Water-cooled air-cooled chiller unit (abbreviated as: water-cooled unit);

- Water-cooled water chiller unit (abbreviated as: water-cooled water chiller unit).

Naming method: The cooling form of the condenser + the heat exchange form of the evaporator.

II.

Common Terms

- Heat

Heat is a form of energy. If an object is heated up, heat is absorbed; if it is cooled, heat is discharged. The international unit is joule (J).

Common units: kJ (kilojoule), BTU (British thermal unit), kCal (kilocalorie) - Refrigeration Capacity

The amount of heat that the air conditioning unit takes away from the air-conditioned area per unit time. The international unit is kW (kJ/s).

Common units: kW (kilowatt), BTU/h (British unit), kCal/h (kilocalorie per hour), RT (refrigeration ton) - Temperature

Temperature represents the degree of coldness or hotness of a substance.

The ways to express temperature are: ℃ (Celsius), ℉ (Fahrenheit), K (Kelvin)

℃ = 5/9(℉ - 32) = K - 273 - Relative Humidity

Relative humidity represents the degree to which water vapor in the air approaches saturation.

Expression method: % (percentage) - Refrigerant

A heat carrier that circulates and transfers heat from the high-temperature end to the low-temperature end in the refrigeration system.

Common ones are: R22, R134a, R410A, R290, R717, R404A, etc. - Energy Efficiency Ratio

The energy efficiency ratio is an important indicator for measuring the economy of an air conditioning unit.

Energy efficiency ratio = Refrigeration capacity / Power consumption - Sensible Heat/Latent Heat

The heat that causes a change in the temperature of an object is called sensible heat.

The heat that only changes the phase state of an object without changing its temperature is called latent heat. - Evaporation/Condensation

Evaporation and condensation are the phase change processes of the refrigerant in the system when it absorbs (releases) heat.

When the refrigerant changes from a liquid state to a gaseous state, it is called evaporation, and it absorbs heat from the surrounding environment;

When the refrigerant changes from a gaseous state to a liquid state, it is called condensation, and it releases heat to the surrounding environment. - Subcooling Degree

The temperature difference between the refrigerant liquid and the saturated liquid at the same pressure is called the subcooling degree, that is, the difference between the condensation saturation temperature of the refrigerant (the corresponding value of the high-pressure gauge) and the temperature of the liquid pipe. - Superheat Degree

The temperature difference between the refrigerant vapor and the saturated vapor at the same pressure is called the superheat degree, that is, the difference between the evaporation saturation temperature of the refrigerant (the corresponding value of the low-pressure gauge) and the return gas temperature.

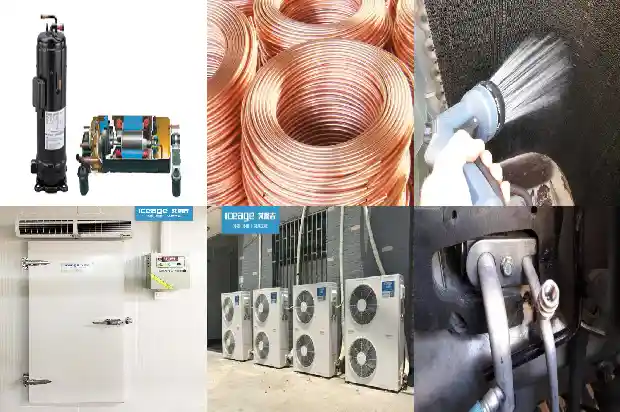

III. Refrigeration Principle and Main Components

Compression Process:

Compress the low-temperature and low-pressure refrigerant gas into a high-temperature and high-pressure refrigerant gas and discharge it into the condenser.

Condensation Process:

The high-temperature and high-pressure gas discharged from the compressor enters the condenser. After transferring heat to the outside air or cooling water, it condenses into a liquid refrigerant and flows towards the throttling device.

Throttling Process:

The refrigerant liquid flowing out of the condenser flows towards the throttling device under high pressure for throttling and pressure reduction.

Evaporation Process:

The refrigerant liquid flowing out of the throttling device flows towards the evaporator, absorbs the heat of the outside (air or water) and evaporates into a gas, thus reducing the temperature of the outside (air or water). The low-temperature and low-pressure gas after evaporation is sucked in by the compressor.

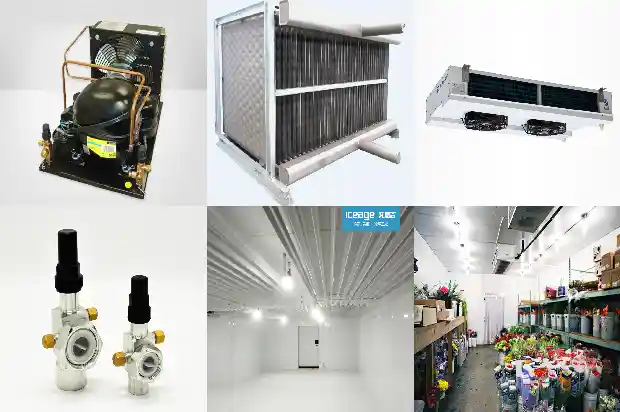

Compressor:

The heart and power of the refrigeration system, which has the function of compressing and driving the refrigerant in the refrigeration system.

Condenser and Evaporator:

The condenser transfers heat to the external environment, and the refrigerant gas cools and liquefies, making the external environment temperature rise.

The evaporator absorbs heat from the external environment, and the refrigerant liquid vaporizes in it, making the external environment temperature decrease.

Dry Evaporator:

The refrigerant in the dry evaporator passes through the heat exchange tubes, and the chilled water runs outside the high-efficiency heat exchange tubes. The heat exchange efficiency of such a heat exchanger is relatively low, and its heat transfer coefficient is only about 2 times that of a smooth tube. However, its advantage is that it is convenient for oil return and the control is relatively simple. The refrigerant charge is about 1/2 to 1/3 of that of a flooded evaporator unit.

Flooded Evaporator:

The operation mode of the flooded evaporator is exactly the opposite of that of the dry evaporator. The chilled water passes through the heat exchange tubes, and the refrigerant completely submerges the heat exchange tubes and evaporates outside the heat exchange tubes after absorbing heat. There are many needle-shaped small holes on the surface of the heat transfer tubes of the flooded evaporator, and there are also spiral protrusions on the inner surface of the tubes to enhance the heat exchange on the chilled water side. This kind of high-efficiency heat transfer tube that simultaneously enhances the boiling outside the tube and the heat transfer inside the tube increases its heat transfer coefficient.

Throttling Mechanism:

The high-pressure refrigerant coming out of the condenser is depressurized and cooled through the expansion valve, making the temperature of the refrigerant lower than the ambient temperature, so that the air conditioning unit has the ability to refrigerate. Currently, the commonly used throttling devices are: thermal expansion valve, orifice plate, capillary tube, manual expansion valve, electronic expansion valve.

Functions of the Expansion Valve:

Throttling and pressure reduction;

Flow control;

Superheat control. The function of controlling the superheat of the refrigerant at the outlet of the evaporator ensures that the evaporation area of the evaporator is fully utilized and can prevent the occurrence of compressor cylinder breakage accidents.

Classification of Thermal Expansion Valves:

Thermal expansion valves are classified according to the structural form into: integral type and assembled type.

According to the pressure balance mode, they can be divided into: internal balance and external balance modes.

According to the flow direction of the working medium, they can be divided into: unidirectional and bidirectional.

Electronic Expansion Valve

Four-Way Valve:

The four-way valve is an important component in the air conditioner and plays a role in changing the flow direction of the refrigerant in the air conditioning system.

Gas-Liquid Separator:

The gas-liquid separator can be installed at the inlet and outlet of the gas compressor for gas-liquid separation.

Receiver:

The receiver plays the roles of storage, gas-liquid separation, filtration, noise elimination, and refrigerant buffering.

Solenoid Valve:

When powered on, the electromagnetic coil generates electromagnetic force to lift the closing member from the valve seat, and the valve opens; when powered off, the electromagnetic force disappears, and the spring presses the closing member against the valve seat, and the valve closes.

Related Articles

- Detailed Explanation of HVAC Pipeline Integration and Pipe Shaft Layout

- HVAC Design | Basics of Cooling Towers

- 【HVAC Design Summary】 - Free Cooling with Cooling Towers

- Obscure Knowledge of Static Pressure, Dynamic Pressure, Latent Heat and Sensible Heat in the HVAC Industry

- Common Faults of HVAC Fan Coil Units

- Myths about "condensate water" in HVAC construction. Know more

- Common Terms in HVAC

- Analysis of Common Auxiliary Components in the Refrigeration System One by One

- A Detailed Analysis of the Nine Reasons for the Low Pressure in the Refrigeration System!

- These Inspections before Starting the Refrigeration Unit Are Very Important~~

- Common Fault Causes of Totally Enclosed Refrigeration Compressors

- Popularize Refrigeration Knowledge You've Never Noticed, Which Is Actually Very Crucial

- Analysis of Common Auxiliary Components in the Refrigeration System

- Does the Refrigeration System Definitely Need to Be Evacuated? What Will Happen If It Isn't?

- Common Faults in Refrigeration Systems and Handling Methods

- Why Should Refrigeration Shut - off Valves Have "Low - Inlet and High - Outlet" Design?

- Four Requirements for Refrigeration Systems Adopting Two - stage Compression Refrigeration Systems

- Screw Compressor Units: Principles, Design and Selection - Essential Guide for Refrigeration Beginners