Installation, Inspection and Debugging of the Cold Storage Body

2025-03-02

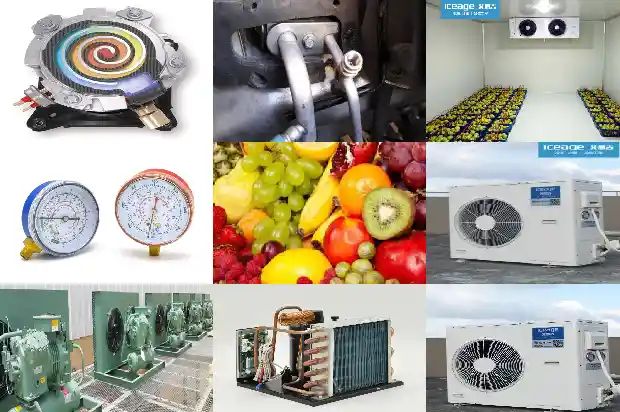

I. Installation Specifications of the Cold Storage Body

Enter the construction site, verify the construction situation according to the construction drawings, and determine the installation positions of the equipment (the cold storage body, drainage door, evaporator, main unit, condenser, control system, etc.).

Floor Installation

Enter the construction site, verify the construction situation according to the construction drawings, and determine the installation positions of the equipment (the cold storage body, drainage door, evaporator, main unit, condenser, control system, etc.).

Floor Installation

- First, level the floor, and then start installing the floor. Select the aesthetically pleasing floorboards and place them in a prominent position, and complete the drainage system for the floor and the evaporator.

- Quality Requirements: The floor should be installed flat. For uneven parts, use materials to level the floor, and lock the hooks between the floorboards to make the cold storage surface flat without a feeling of hollowness. (Note: If the cold storage body is installed outdoors in the north, the drainage pipe of this drainage system needs to be insulated).

Upright Plate Installation - Work Content: According to the site conditions, select a corner first and position it (that is, lock the upright plate and the floor). Extend from this corner to both sides, only lock the upright plates together. When encountering a corner, position it. Place the aesthetically pleasing plates in a prominent position. When installing the side where the evaporator is located, make the drainage pipe in advance. An U-shaped bend needs to be made outside the cold storage and silicone sealant should be applied.

- Quality Requirements: The prominent surface of the upright plate should be flat, there should be no dents on the cold storage plate, the upper surface of the upright plate should be flush, the gaps between the upright plates should be even, and the upright corners in the prominent position should be flush with the floor corners.

Ceiling Plate Installation - Work Content: First, select one end to position the ceiling corner plate and extend the laying. Lock the ceiling plates together. When installing, ensure that the ceiling plate at the prominent end and the upright plate are flat and locked to prevent displacement.

- Quality Requirements: Select aesthetically pleasing ceiling plates for the prominent position. The joints between the ceiling plates and the upright plates should be flush with small gaps, and the ceiling plates inside the cold storage should be flat.

- After the ceiling, floor, and upright plates are generally installed, correct and flush the connections between the ceiling and the upright plates, and between the upright plates and the floor, and lock all the hooks between them.

- For the cold storage plates that need to be flared, the flared parts need to be polished to be free of burrs. For the cold storage plates that need to be installed with angle aluminum, apply silicone sealant first, and then install the angle aluminum to ensure the tightness.

- After the cold storage body is installed, allocate time to apply silicone sealant. The silicone sealant joints should be smooth and glossy. It is best to apply the silicone sealant at the end of the workday to prevent damage.

II. Installation Specifications of the Evaporator - Installation Content: First, drill the holes for the hoisting screws, and drill the holes for the copper pipes and wires. Then, trim the latter two holes to prevent potential hazards caused by sharp edges. The back of the evaporator with a self-equipped drainage pipe should be positioned 300MM away from the upright plate. The drainage hole of the evaporator should be perpendicular to the pre-installed drainage hole position on the upright plate, and the height difference between the two is 250MM. For a freezer, install a drainage heating wire inside the drainage pipe. The heating part of the drainage heating wire can only extend 50MM into the cold storage plate. Insulate the outside of the drainage pipe. For a refrigerator, no heating wire is needed, and the other aspects are the same.

- Hoisting Precautions: The air inlet of the evaporator should not face the cold storage door. It is best to hoist the evaporator at the longest end of the cold storage, and the air outlet of the evaporator should preferably not face the door.

- Installation Specifications of the Main Unit of the Cold Storage Unit: The closer the position of the main unit is to the evaporator, the better. It should be easy to maintain and have good heat dissipation. If it is moved outside, a rain shelter needs to be installed. Anti-vibration gaskets should be placed at the four corners of the main unit position. Install it horizontally and firmly, and make sure it is not easily touched by people.

- Condenser Installation: The closer the installation position of the condenser is to the main unit, the better. It is best to be slightly above the main unit.

The installation position of the condenser should have the best heat dissipation environment. The air inlet should not face the air outlet of other equipment, especially oily gas. The air outlet should not be short-circuited and should not face other windows and equipment. It should be 2M above the ground, and be installed horizontally and firmly.

- Copper Pipe Arrangement: All copper pipes need to be respectively passed through the insulation pipes and bundled together with the wires in the same direction using air conditioner tie wraps. Try to make them go in a straight line and fix them in sections. The joints of the insulation pipes should be sealed with electrical tape.

2.3 Wire Arrangement: In addition to bundling all the wires with air conditioner tie wraps, they need to be protected by passing through corrugated hoses or wire troughs. The temperature display wires should be arranged as far away from other wires as possible.

III. Connection of the Refrigeration System

Since the main unit, condenser, and evaporator have all been pressure-tested and sealed in the factory, there should be pressure when they are opened, so that it can be checked whether there is a leak. The copper pipes from the factory should have dust-proof measures at both ends. During construction, pay attention to sealing them at any time to prevent water and dust from entering the pipes. - Configure the wires according to the performance of each electrical appliance. The wire diameter should meet the requirements, the joints should be firm. If it is necessary to protect the wires by passing them through pipes, do not omit this step, and connect the power correctly.

When the wires enter the junction box hole of the evaporator, they need to be sealed with silicone sealant. If the lamp is powered by more than 36V electricity, a grounding wire is required. The power supply entering the electrical cabinet of the main unit should be in a three-phase five-wire system with a reliable ground connection.

- Fix the temperature controller on the ceiling plate. The probe and the temperature display probe should be passed into the return air outlet of the evaporator in the cold storage together and be suspended. The defrosting temperature controller is also fixed on the ceiling plate, and the probe should be passed through another hole into the return air outlet of the evaporator in the cold storage, and the probe should be inserted into the fins (not close to the heating tube).

- If it is impossible to stand on the ceiling plate, fix the temperature controller and the defrosting temperature controller at a corner behind the evaporator in the cold storage. Seal all the wiring connections, and the other aspects are the same as above.

- The balance hole (pressure equalizing valve) should not be installed in a prominent position or on the upright plate of the air outlet. Drill a hole 200MM below the upper part of the upright plate.

IV. Debugging Specifications of the Cold Storage Equipment - Use nitrogen to check the system for leaks. If there is no problem within 12 hours, the system can be evacuated. Check whether all the wiring and cable arrangements are correct and meet the requirements, and check whether the power supply meets the standards.

- Power-on Test of the Refrigeration System: After all the components of the refrigeration system are operating normally, start the machine and replenish Freon until the liquid level is full. At this time, adjust the setting value of the temperature controller, and observe the low-pressure value when the temperature reaches the termination temperature. Check whether the high and low pressures can provide protection, and adjust the protection value of the thermal relay to 2.5 times the normal starting current.

Also, manually test its performance.

- Power-on Test of the Defrosting System: Adjust the defrosting timer to a frequency of 4-6 times a day, and the defrosting time is 10-60 minutes, with each defrosting lasting 25 minutes. Set the defrosting termination temperature at +20°C. Check whether the heating wire is working normally during defrosting, and whether the drainage heating wire is heating normally. Special Reminder: The defrosting time is for reference only. In actual application, the defrosting time and termination temperature should be set according to the comprehensive situation such as the temperature of the cold storage system.

- If the horizontal distance between the radiator and the main unit or between the main unit and the evaporator is greater than 10M, and the height difference is greater than 5M, an appropriate amount of refrigeration oil can be replenished.

- After all the data are set and debugged, reset the start and stop of the machine three times to check whether all the components can work normally. At this time, invite the customer to check and accept the cold storage.

- After the above work is completed, clean the sanitation inside and outside the cold storage, invite the customer to check and accept the entire cold storage, sign for confirmation, and hand it over.

Related Articles

- Installation Precautions and Accessory Selection for Cold Storage Unit

- Matters Concerning the Installation of Parallel Units

- Advanced Guide! Design and Installation of Refrigeration System Pipelines

- What Are the Acceptance Standards for Cold Storage Design and Installation?

- What issues should be noted during the installation of a small - scale cold storage?

- Instructions for Welding and Drainage in the Installation of Refrigeration Equipment Pipelines

- What is the Correct Operation Method of the Distribution Box during Cold Storage Installation?

- What Issues Should Be Noted in Cold Storage Installation and Construction?

- What Special Requirements are There for the Installation of Tea Cold Storage?

- Operating Principle and Standard Installation Steps of Multi - split Systems in Refrigerant Air - conditioning Systems

- How to Identify the Quality of Refrigeration Equipment Installation Materials?

- How to Identify Installation Materials for Refrigeration Equipment

- Knowledge, Installation and Maintenance of Cold Storage Systems

- Precautions for the Installation and Use of Water Flow Switches

- What safety measures should be paid attention to during the installation of cold storage?

- What are the precooling methods after the installation of cold storage?

- Selection and Installation of Thermal Expansion Valves

- Return Bend Setup and Installation Technical Requirements