Precautions for the Installation of Automatic Instruments in Refrigeration Devices (Part One)

2025-03-09

Automatic instruments, also known as process measurement and control instruments, are usually simply referred to as "instruments". They are the general term for instrument devices and instrument systems used for measuring and controlling measured variables and controlled variables. Sometimes, they also refer to individual instrument devices and equipment used for detection and control. For example, a display instrument refers to an instrument that displays the measured value; a control instrument refers to an instrument used to control the controlled variable. In addition to the control function itself, some control instruments also include monitoring and safety protection functions.

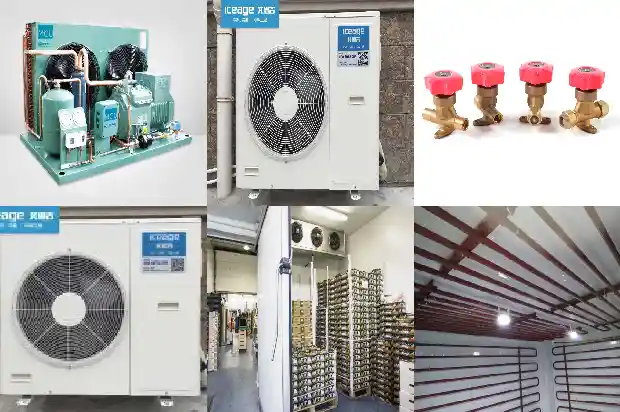

In refrigeration devices, instruments directly installed on refrigeration equipment and pipelines include pressure gauges, pressure controllers, differential pressure controllers, level gauges, etc., and some are installed in on-site control cabinets and control boxes.

- First, check the outer packaging of the instrument, which should be in good condition without damage.

- Check the model, specification, material, and quantity of the instrument, which should be consistent with the provisions of the design documents, and there should be no damage or shortage.

- The nameplate markings, accessories, and spare parts of the instrument should be complete.

- The technical documents and quality certificates attached to the instrument should be complete.

- The surface should be flat, and the coating on the inner and outer surfaces should be intact.

- The external dimensions and the dimensions of the installation holes should comply with the provisions of the design documents.

After the instrument passes the inspection and is not installed temporarily and needs to be stored in the warehouse, it should be stored according to the required storage conditions, and the identification should be obvious and clear.

During the installation and construction process, the installed instrument equipment should be protected.

Instruments installed on equipment and pipelines should be installed at the positions specified in the design documents. When the design documents do not make specific provisions, the following general precautions should be taken during installation:

- The position where the instrument is installed should have sufficient light. Especially for instruments that display numerical values, they should be installed in a position where the display value is easy to observe, and the operation and maintenance should be convenient.

- Generally, the center of the installed display instrument should be at a height of 1.

2m - 1.5m from the operating ground.

- The instrument should not be installed in positions with vibration, humidity, susceptibility to mechanical damage, strong electromagnetic field interference, high temperature, drastic temperature changes, and corrosive gases.

- The detecting element should be installed at a position that can truly reflect the input variable.

- Before installation, the instrument should be checked against its model, specification, material, and accessories according to the design documents.

- During the installation process, the instrument should not be struck or vibrated. The connection and fixing parts between the instrument and the equipment, pipeline, or component should be evenly stressed and should not bear abnormal external forces. After installation, the instrument should be firm and upright.

- Instruments directly installed on pipelines should preferably be installed after the pipeline is purged. When installed simultaneously with the pipeline, the instrument should be removed before the pipeline is purged.

- After the instruments directly installed on the equipment or pipeline are installed, a pressure test should be carried out.

- The cover and the inlet of the instrument junction box (box) should be closed in a timely manner during the construction process.

- The instrument junction box (box) should be sealed, and the inlet should not face upward.

- When measuring the insulation resistance of the instrument and the instrument power supply equipment, measures should be taken to prevent the weak current equipment and electronic components from being damaged.

- The installed instrument nameplate, instrument tag number, and other identifications should be complete, firm, and clear.

- For instruments with capillary tubes, protective measures should be taken for the laying of the capillary tubes during installation. The bending radius should not be less than 50mm, and heat insulation measures should be taken when the surrounding temperature changes drastically.

- The instrument circuits of fieldbus instruments are connected in parallel. The number of instruments on each bus and the maximum distance of the bus should comply with the provisions of the design documents.

The installation of on-site junction boxes should comply with the following provisions:

- The ambient temperature around should not be higher than 45°C.

- The distance from each detection point should be appropriate, and the height of the center of the box from the operating ground should preferably be 1.2m - 1.5m.

- It should not affect the operation, passage, and equipment maintenance.

- The junction box should be sealed and marked with a number, and the wiring in the box should be marked with a wire number.

- When fixing the junction box made of stainless steel, it should not be in direct contact with carbon steel materials.

Installation of Instrument Panels and Instrument Cabinets:

- The installation position and planar layout of the instrument panels, cabinets, and operation consoles should be constructed according to the design documents. Generally, they should be installed in positions with sufficient light, good ventilation, and convenient operation and maintenance.

- The manufacturing dimensions of the section steel bases of the instrument panels, cabinets, and operation consoles should match those of the panels, cabinets, and operation consoles. The allowable deviation of the straightness should be 1mm/m; when the length of the section steel base is greater than 5m, the allowable deviation of the full length should be 5mm.

- When installing the section steel bases of the instrument panels, cabinets, and operation consoles, the upper surface should be kept horizontal, and the allowable deviation of the levelness should be 1mm/m; when the length of the section steel base is greater than 5m, the allowable deviation of the full-length levelness should be 5mm.

- The section steel bases of the instrument panels, cabinets, and operation consoles should be installed and aligned before the ground construction is completed, and the upper surface should preferably be higher than the ground. The section steel bases should be treated with anti-corrosion measures.

- When the instrument panels, cabinets, and operation consoles are installed in a vibrating place, anti-vibration measures should be taken according to the provisions of the design documents.

- When the instrument panels, cabinets, and operation consoles are installed in a dusty, humid, corrosive gas, or explosive and fire-hazardous environment, they should be selected according to the provisions of the design documents and sealed.

- The connections between the instrument panels, cabinets, operation consoles, and between the equipment components inside the panels, cabinets, and operation consoles should be firm, and the fasteners used for installation should be made of rust-proof materials. Welding should not be used for installation and fixation.

- The installation of individual instrument panels, cabinets, and operation consoles should comply with the following provisions:

- It should be firmly fixed.

- The allowable deviation of the perpendicularity should be 1.5mm/m.

- The allowable deviation of the levelness should be 1mm/m.

- The installation of rows of instrument panels, cabinets, and operation consoles should also comply with the following provisions:

- The height difference between the tops of two adjacent panels, cabinets, and operation consoles of the same series and specification should not be greater than 2mm.

- When there are more than two connection points between the panels, cabinets, and operation consoles of the same series and specification, the height difference between the tops should not be greater than 5mm.

- The deviation of the flatness of the front surface at the joint between two adjacent panels, cabinets, and operation consoles should not be greater than 1mm.

- When there are more than 5 connection points between the panels, cabinets, and operation consoles, the deviation of the flatness of the front surface should not be greater than 5mm.

- The gap at the joint between two adjacent panels, cabinets, and operation consoles should not be greater than 2mm.

- During the handling and installation of the instrument panels, cabinets, and operation consoles, there should be no deformation or damage to the surface coating.

Related Articles

- Installation Precautions and Accessory Selection for Cold Storage Unit

- Operation and Precautions of Frozen and Refrigerated Auxiliary Equipment

- Precautions for Using Rotary Refrigeration Compressors

- Precautions for Commissioning of Screw Parallel Units

- Four Combustible and Explosive Refrigerants: Precautions When in Use!

- Accident Handling and Precautions for Circulating Water Pumps

- What Precautions Should Be Taken When Using a Fresh - keeping Cold Storage in Summer?

- Operations and Precautions for Multi - split Air Conditioners: Blowing Debris, Air Tightness, Vacuum Drying, and Refrigerant Charging

- Precautions for the Installation and Use of Water Flow Switches

- Precautions for the Hot Gas Bypass Valve of Refrigeration Units in Cold Storage

- Precautions for Inspecting Valves in Refrigeration Systems

- Parallel Installation and Precautions for Scroll Compressors

- Installation and Oil Return Precautions for Refrigeration Equipment Pipelines

- Precautions for Replacing Refrigeration Compressor Refrigerant Oil

- Precautions for Cold Storage Design

- Installation and Welding of Precision Air Conditioning Systems

- Comprehensive! Piping and Installation of VRF (Variable Refrigerant Flow) System

- What Issues Should Be Considered in the Installation of a Cold Storage?