Principles of Refrigeration Systems and Functions of Components Explained

2024-09-28

I. Refrigeration Principle

The compressor compresses gaseous refrigerant into high-temperature and high-pressure gaseous refrigerant and sends it to the outdoor unit condenser to become liquid refrigerant. The liquid refrigerant is throttled by a throttling mechanism.

Then the refrigerant enters the evaporator to absorb heat from the air and vaporize into gaseous refrigerant. Then the gaseous refrigerant returns to the compressor for continuous compression and continues the refrigeration cycle.

During heating, there is a four-way valve that makes the flow direction of the refrigerant in the condenser and evaporator opposite to that during refrigeration. Therefore, during heating, cold air is blown outdoors and hot air is blown by the indoor unit.

The compressor compresses gaseous refrigerant into high-temperature and high-pressure gaseous refrigerant and sends it to the outdoor unit condenser to become liquid refrigerant. The liquid refrigerant is throttled by a throttling mechanism.

Then the refrigerant enters the evaporator to absorb heat from the air and vaporize into gaseous refrigerant. Then the gaseous refrigerant returns to the compressor for continuous compression and continues the refrigeration cycle.

During heating, there is a four-way valve that makes the flow direction of the refrigerant in the condenser and evaporator opposite to that during refrigeration. Therefore, during heating, cold air is blown outdoors and hot air is blown by the indoor unit.

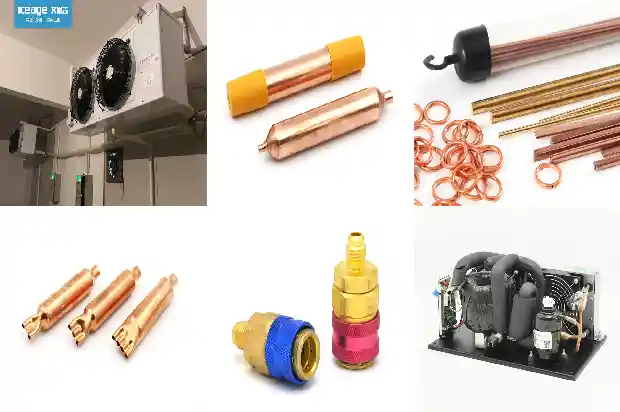

II. Main Components of Refrigeration Air Conditioners

- Compressors can be divided into: centrifugal, rotary, and rotary.

Common compressors are:

Scroll compressor;

Screw compressor;

Piston compressor;

Centrifugal compressor.

Fully enclosed piston compressor: 1-20 refrigeration tons, used in commercial buildings or household facilities.

Semi-enclosed piston compressor: mostly used in refrigeration and freezing equipment.

Rotary compressor: now mostly used in refrigeration equipment with less than 7 horsepower. The rolling rotor compressor has few parts, simple structure, no suction valve, small clearance volume, small size, light weight, and stable operation.

Scroll compressor: single-unit capacity of 3HP~25HP, mainly used in central air conditioners (home and commercial). The scroll machine has high efficiency, is conducive to energy saving, has low noise, small size, light weight, stable operation, small air flow pulsation, and long service life.

Screw compressor: single-unit capacity of 40HP~400HP, mainly used in commercial central air conditioners and other larger equipment. It has a simple structure, fewer wearing parts, low exhaust temperature under a large pressure difference, and good gas transmission regulation performance.

Centrifugal compressor: Centrifugal refrigeration compressors rely on changes in kinetic energy to increase gas pressure during operation. Centrifugal compressors have large single-unit refrigeration capacity and stable operation. - Condensers and evaporators

Condensers can be divided into:

Fin heat exchanger:

Characteristics: No cooling water is required. It is easy to install, has a simple manufacturing process, and is reliable in use.

Disadvantages: The heat exchange effect is relatively worse than that of water-cooled heat exchangers. It has a large volume, and dust and dirt are easily accumulated on the surface to affect heat exchange and need to be cleaned in time.

Plate heat exchanger:

Characteristics: Compact structure, easy installation, light weight, small water consumption, and high heat exchange efficiency. Removable plate heat exchanger ~ compact structure, high flexibility, convenient maintenance, and high heat exchange efficiency.

Greatly affected by water quality.

If the water quality is poor, it is easy to be clogged and corroded. In addition, if there is a lack of protection measures, it is easy to be frozen and damaged.

Casing heat exchanger:

Characteristics: Simple production, relatively low requirements for water quality, good heat exchange effect, and not easy to be clogged.

Disadvantages: Relatively large volume and weight, and large fluid pressure loss. Mainly used in small and medium-sized devices.

Shell and tube heat exchanger:

Simple structure, high heat transfer efficiency, good heat exchange effect, and wide working adaptability. However, inspection, cleaning, and disassembly are more troublesome, and leakage is easy to occur at the detachable connection.

Evaporator: In a flooded evaporator, the refrigerant boils and evaporates outside the tube, while in a dry evaporator, it is the opposite.

Throttling mechanism:

The main function of the throttling mechanism is to throttle and reduce the pressure of the high-pressure liquid refrigerant coming out of the condenser to the evaporation pressure. In addition, according to the system load changes, adjust the amount of refrigerant liquid entering the evaporator.

III. Other Refrigeration Auxiliary Components

Temperature controller: The air conditioning temperature controller uses programmed editing to control and send various signals to the actuator through programs, so as to achieve the purpose of controlling the air conditioning fan bypass pipe and the electric two-way valve.

Gas-liquid separator: Usually installed on the suction pipe of the compressor, it can separate the liquid in the refrigerant returning to the compressor and store it at the bottom to prevent the compressor from experiencing liquid hammer.

Receiver: Temporarily store excess refrigerant in the system and adjust the amount of refrigerant in the system.

Four-way reversing valve: Heat pump air conditioners change the flow direction of the refrigerant through the four-way reversing valve so that it can cool in summer and heat in winter.

High and low pressure switch: The high and low pressure switch is an electrical switch controlled by pressure signals to prevent the pressure on the air conditioning pipeline from being too high or too low.

Oil pressure protector: Ensure that the compressor has enough lubricating oil.

Expansion valve: It can create a huge pressure difference between the high and low pressure of the system, so that the high-pressure refrigerant liquid at the outlet of the expansion valve quickly expands and evaporates. It absorbs heat from the air through the pipe wall for heat exchange.

Drying filter: Used to filter moisture and impurities to keep the refrigeration system dry and clean. Usually installed before the throttling element.

Oil separator: Its function is to separate the lubricating oil in the high-pressure steam discharged from the refrigeration compressor to ensure the safe and efficient operation of the device.

Evaporator pressure regulating valve: It is to prevent the evaporator pressure from dropping below the specified value. Sometimes it is also used to adjust the evaporator pressure to adapt to load changes (generally used in refrigeration and freezing equipment).

Fan speed regulator: Mainly used for speed regulation of the fan motor of the outdoor air-cooled condenser of refrigeration equipment or for speed regulation of air coolers.

Solenoid valve: Used to automatically connect and cut off the pipeline of the refrigeration system. It is controlled by the electromagnetic suction generated by the current passing through the electromagnet to open and close the valve.

Sight glass: The function of the sight glass is to show whether there is refrigerant in the refrigeration system and detect whether there is water vapor in the refrigerant. The color indicator in the sight glass can show the water vapor content; green: the refrigerant does not contain water vapor at a dangerous level; yellow: the water vapor content in the liquid pipeline at the front end of the expansion valve is too high.

Function of check valve: Ensure the correct flow direction of the refrigerant.

Fan: Common forms are axial flow and centrifugal. According to different air volumes and pressure heads, axial flow is mostly used in outdoor units, and centrifugal is mainly used in indoor units.

Fan speed regulator: Mainly used for speed regulation of the fan motor of the outdoor air-cooled condenser of refrigeration equipment or for speed regulation of air coolers.

Auxiliary electric heating: Sometimes to ensure the heating effect under extreme weather conditions, auxiliary electric heating can be added to the indoor unit heat exchanger of the air conditioner. There are two types of electric heating elements, PTC type and electric heating tube type. Small air conditioners often use PTC type, while large and medium-sized air conditioners use electric heating tube heaters.

Subcooling tube group: The subcooling tube group is mainly used on the refrigerant pipeline of the outdoor unit of the air conditioner coming out of the condenser. The purpose is to ensure that the refrigerant entering the indoor unit evaporator is in a liquid state by increasing the degree of subcooling of the refrigerant and prevent the refrigerant from evaporating in advance.

Temperature sensor: The temperature sensor senses the indoor and outdoor temperatures. The temperature sensors used in air conditioners mainly use negative temperature coefficient thermistors (also known as NTC thermistors).

Water pressure differential switch: By detecting the water pressure difference between the inlet and outlet of the heat exchanger and comparing it with the corresponding pressure difference of the operating flow rate, a switch signal is output to accurately control the water flow.

Air release valve: When air is mixed into the water system, release the air through the air release valve. The air release valve should be installed at the highest point of the water system or at a local highest point. If there is an extension tube, pay attention to insulation. After the water system is turned on, the air in the system should be released first through the air release valve.

Waterway safety valve: Automatically opens when the water system pressure is too high for protection.

Water pump: Provides power for the water system circulation.

Target flow switch: When the flow changes, the water flow exerts a force on the target, causing the lever to rotate and making the permanent magnet generate a certain displacement, so that the circuit in the magnetic induction head is closed or opened to achieve the purpose of alarming or automatic control.

Expansion tank: In a closed circulating water system, due to changes in water temperature, the volume expands. The function of the expansion tank is to absorb this part of water.

Water pressure gauge: Measures the inlet and outlet water pressure of the equipment water system. Generally, a water pressure gauge with a range of 0.6MPa is sufficient for the water system installation. For large water systems, a water pressure gauge with a range of more than 1.0MPa is required.

Make-up water valve: When the system pressure is less than the set pressure, the valve automatically opens to replenish water to the system. The installation of the make-up water valve is convenient for adjustment and shutoff. The make-up water pressure of the make-up water valve is generally an adjustable value, which is generally slightly lower than the pressure when the unit water system is operating normally.

Temperature controller: The air conditioning temperature controller uses programmed editing to control and send various signals to the actuator through programs, so as to achieve the purpose of controlling the air conditioning fan bypass pipe and the electric two-way valve.

Gas-liquid separator: Usually installed on the suction pipe of the compressor, it can separate the liquid in the refrigerant returning to the compressor and store it at the bottom to prevent the compressor from experiencing liquid hammer.

Receiver: Temporarily store excess refrigerant in the system and adjust the amount of refrigerant in the system.

Four-way reversing valve: Heat pump air conditioners change the flow direction of the refrigerant through the four-way reversing valve so that it can cool in summer and heat in winter.

High and low pressure switch: The high and low pressure switch is an electrical switch controlled by pressure signals to prevent the pressure on the air conditioning pipeline from being too high or too low.

Oil pressure protector: Ensure that the compressor has enough lubricating oil.

Expansion valve: It can create a huge pressure difference between the high and low pressure of the system, so that the high-pressure refrigerant liquid at the outlet of the expansion valve quickly expands and evaporates. It absorbs heat from the air through the pipe wall for heat exchange.

Drying filter: Used to filter moisture and impurities to keep the refrigeration system dry and clean. Usually installed before the throttling element.

Oil separator: Its function is to separate the lubricating oil in the high-pressure steam discharged from the refrigeration compressor to ensure the safe and efficient operation of the device.

Evaporator pressure regulating valve: It is to prevent the evaporator pressure from dropping below the specified value. Sometimes it is also used to adjust the evaporator pressure to adapt to load changes (generally used in refrigeration and freezing equipment).

Fan speed regulator: Mainly used for speed regulation of the fan motor of the outdoor air-cooled condenser of refrigeration equipment or for speed regulation of air coolers.

Solenoid valve: Used to automatically connect and cut off the pipeline of the refrigeration system. It is controlled by the electromagnetic suction generated by the current passing through the electromagnet to open and close the valve.

Sight glass: The function of the sight glass is to show whether there is refrigerant in the refrigeration system and detect whether there is water vapor in the refrigerant. The color indicator in the sight glass can show the water vapor content; green: the refrigerant does not contain water vapor at a dangerous level; yellow: the water vapor content in the liquid pipeline at the front end of the expansion valve is too high.

Function of check valve: Ensure the correct flow direction of the refrigerant.

Fan: Common forms are axial flow and centrifugal. According to different air volumes and pressure heads, axial flow is mostly used in outdoor units, and centrifugal is mainly used in indoor units.

Fan speed regulator: Mainly used for speed regulation of the fan motor of the outdoor air-cooled condenser of refrigeration equipment or for speed regulation of air coolers.

Auxiliary electric heating: Sometimes to ensure the heating effect under extreme weather conditions, auxiliary electric heating can be added to the indoor unit heat exchanger of the air conditioner. There are two types of electric heating elements, PTC type and electric heating tube type. Small air conditioners often use PTC type, while large and medium-sized air conditioners use electric heating tube heaters.

Subcooling tube group: The subcooling tube group is mainly used on the refrigerant pipeline of the outdoor unit of the air conditioner coming out of the condenser. The purpose is to ensure that the refrigerant entering the indoor unit evaporator is in a liquid state by increasing the degree of subcooling of the refrigerant and prevent the refrigerant from evaporating in advance.

Temperature sensor: The temperature sensor senses the indoor and outdoor temperatures. The temperature sensors used in air conditioners mainly use negative temperature coefficient thermistors (also known as NTC thermistors).

Water pressure differential switch: By detecting the water pressure difference between the inlet and outlet of the heat exchanger and comparing it with the corresponding pressure difference of the operating flow rate, a switch signal is output to accurately control the water flow.

Air release valve: When air is mixed into the water system, release the air through the air release valve. The air release valve should be installed at the highest point of the water system or at a local highest point. If there is an extension tube, pay attention to insulation. After the water system is turned on, the air in the system should be released first through the air release valve.

Waterway safety valve: Automatically opens when the water system pressure is too high for protection.

Water pump: Provides power for the water system circulation.

Target flow switch: When the flow changes, the water flow exerts a force on the target, causing the lever to rotate and making the permanent magnet generate a certain displacement, so that the circuit in the magnetic induction head is closed or opened to achieve the purpose of alarming or automatic control.

Expansion tank: In a closed circulating water system, due to changes in water temperature, the volume expands. The function of the expansion tank is to absorb this part of water.

Water pressure gauge: Measures the inlet and outlet water pressure of the equipment water system. Generally, a water pressure gauge with a range of 0.6MPa is sufficient for the water system installation. For large water systems, a water pressure gauge with a range of more than 1.0MPa is required.

Make-up water valve: When the system pressure is less than the set pressure, the valve automatically opens to replenish water to the system. The installation of the make-up water valve is convenient for adjustment and shutoff. The make-up water pressure of the make-up water valve is generally an adjustable value, which is generally slightly lower than the pressure when the unit water system is operating normally.

Related Articles

- Principles, Components and Heat Recovery of Modular Units

- Characteristics and principles of air-cooled and water-cooled units

- Have You Encountered the Three Common Problems of Refrigeration Compressors?

- How to Calculate Refrigeration Load? And What Are the Issues?

- What to Do if the Compressor of a Frozen and Refrigerated Display Cabinet Runs but the Refrigeration Effect Is Poor?

- Instructions for Welding and Drainage in the Installation of Refrigeration Equipment Pipelines

- Common Pressure Valves and Protection Devices in Refrigeration Units

- Precautions for Using Rotary Refrigeration Compressors

- What Misconceptions Should Be Avoided in Low - temperature Refrigeration System Repairs

- Essential for Maintenance! Parameters and Phenomena of Normal Operation of Refrigeration and Heating Systems

- Composition and Common Faults of Screw Refrigeration Compressors

- How to Read the High - and Low - Pressure Gauges of Refrigeration Air - conditioners?

- What is Cascade Refrigeration?

- Introduction to Control Valves in Refrigeration Systems

- Welding Equipment Used in Refrigeration System Maintenance

- Where Lie the Key Construction Technologies of the Ammonia Refrigeration System?

- What to Do When a Refrigeration Unit Malfunctions?

- Could a Tiny Copper Tube Cause a Multi - split Air Conditioner to Stop Cooling? Refrigeration Workers Must Pay Attention!