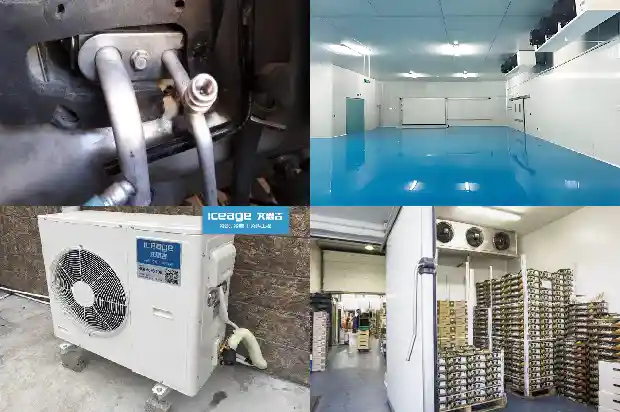

Refrigeration System Circulation and Components for Freezing and Cold Storage

2024-12-20

There are many refrigeration methods, and the commonly used ones are as follows:

Liquid vaporization refrigeration;

Gas expansion refrigeration;

Vortex tube refrigeration;

Thermoelectric refrigeration;

Among them, liquid vaporization refrigeration is the most widely used. It achieves refrigeration by utilizing the endothermic effect during liquid vaporization. Vapor compression, absorption, vapor injection and adsorption refrigeration all belong to liquid vaporization refrigeration.

Vapor compression refrigeration belongs to phase change refrigeration, that is, it obtains cooling capacity by using the endothermic effect when the refrigerant changes from a liquid state to a gaseous state. It consists of four major components: a compressor, a condenser, a throttling device and an evaporator. They are connected in sequence by pipes to form a closed system.

Liquid vaporization refrigeration;

Gas expansion refrigeration;

Vortex tube refrigeration;

Thermoelectric refrigeration;

Among them, liquid vaporization refrigeration is the most widely used. It achieves refrigeration by utilizing the endothermic effect during liquid vaporization. Vapor compression, absorption, vapor injection and adsorption refrigeration all belong to liquid vaporization refrigeration.

Vapor compression refrigeration belongs to phase change refrigeration, that is, it obtains cooling capacity by using the endothermic effect when the refrigerant changes from a liquid state to a gaseous state. It consists of four major components: a compressor, a condenser, a throttling device and an evaporator. They are connected in sequence by pipes to form a closed system.

Main refrigeration components and accessories

- Compressor:

The compressor is divided into three structures: open type, semi-open type and hermetic type. The function of the compressor is to suck in low-temperature refrigerant from the evaporator side, compress it into high-pressure and high-temperature refrigerant vapor, and send it to the condenser. - Condenser:

The condenser is a heat exchange device that transfers the refrigerating capacity of the evaporator in the refrigeration system together with the compression indicated work of the compressor to the environmental medium (cooling water or air). According to the cooling method, condensers can be divided into air-cooled type, water-cooled type and evaporative type. - Evaporator:

The evaporator means that the refrigerant liquid boils at a relatively low temperature and absorbs the heat of the cooled medium (air or water) to achieve the purpose of refrigeration. - Solenoid valve:

The solenoid valve is an electrically controlled automatic shut-off valve.

It is usually installed on the system pipeline and is used as the actuating element of the two-position regulator for automatically connecting and disconnecting the pipelines of the refrigeration system. The solenoid valve is usually installed between the expansion valve and the condenser. Its position should be as close to the expansion valve as possible, because the expansion valve is just a throttling element and cannot be tightly closed by itself, so the solenoid valve needs to be used to cut off the liquid supply pipeline.

- Thermostatic expansion valve:

The thermostatic expansion valve is commonly used in refrigeration units to regulate the refrigerant flow rate. It is both a regulating valve for controlling the liquid supply amount to the evaporator and a throttling valve of the refrigeration unit. The thermostatic expansion valve adjusts the liquid supply amount by utilizing the change in the degree of superheat of the refrigerant at the outlet of the evaporator. The thermostatic expansion valve is connected to the inlet pipe of the evaporator, and the temperature sensing bulb is attached to the outlet (outlet gas) pipe of the evaporator. Usually, according to the different structures of the thermostatic expansion valve, it is divided into:

(1) Internally balanced thermostatic expansion valve;

(2) Externally balanced thermostatic expansion valve.

Internally balanced thermostatic expansion valve: It consists of a temperature sensing bulb, a capillary tube, a valve seat, a diaphragm, a push rod, a valve needle and a regulating mechanism, etc. The internally balanced thermostatic expansion valve is generally used for small evaporators.

Externally balanced thermostatic expansion valve: For evaporators with long pipelines or large resistance, the externally balanced thermostatic expansion valve is mostly used. For evaporators of the same size, when used in high-temperature cold storage, the internally balanced expansion valve can be selected, while when used in low-temperature cold storage, the externally balanced expansion valve may need to be selected. - Oil separator:

An oil separator is usually installed between the compressor and the condenser to separate the refrigeration oil carried in the refrigerant vapor. The refrigeration oil is returned to the crankcase of the compressor by using the oil return device. The commonly used structures of the oil separator are centrifugal type and filter type. - Gas-liquid separator:

It separates gaseous refrigerant from liquid refrigerant to prevent liquid slugging of the compressor; it stores the refrigerant liquid in the refrigeration cycle and adjusts the liquid supply amount according to the load change. - Receiver:

By setting a receiver, the liquid storage capacity of the receiver can be utilized to balance and stabilize the refrigerant circulation amount in the system, so that the refrigeration unit is in a normal operating state. The receiver is generally set between the condenser and the throttling element. In order to make the liquid refrigerant in the condenser enter the receiver smoothly, the position of the receiver should be lower than that of the condenser. - Drier:

In order to ensure the normal circulation of the refrigerant, the refrigeration system must be kept clean and dry. The drier-filter is usually installed before the throttling element. When the liquid refrigerant passes through the drier-filter first, the blockage phenomenon in the throttling element can be effectively prevented. - Sight glass:

It is mainly used to indicate the condition of the refrigerant in the liquid pipeline of the refrigeration unit and the water content in the refrigerant. Usually, different colors are marked on the case of the sight glass to indicate the water content of the refrigerant in the system. - High and low pressure relays:

When the discharge pressure of the compressor is too high, it will automatically disconnect and stop the compressor from working. After the cause of the high pressure is eliminated, the compressor can be started only by manual reset (fault alarm). When the suction pressure drops to the set lower limit, it will automatically disconnect and stop the compressor from working. When the suction pressure rises back to the set upper limit, the compressor will be powered on again. - Oil pressure differential relay:

It is an electrical switch that uses the suction and discharge pressure difference of the lubricating oil pump as the control signal. When the pressure difference is less than the set value, it will make the compressor stop and play a protective role. - Temperature relay:

It uses temperature as the control signal to control the temperature of the cold storage. It directly controls the start and stop of the compressor by controlling the on-off of the liquid supply solenoid valve. When there are multiple cold storages for one compressor, the temperature relays of each cold storage can be connected in parallel to control the automatic start and stop of the compressor. - Refrigerant:

Refrigerant, also known as coolant or refrigerant gas, is a medium substance used to complete energy conversion in various heat engines. These substances usually increase power through reversible phase changes (such as gas-liquid phase change). - Refrigeration oil:

The main functions of refrigeration oil are lubrication, sealing, cooling and filtration. In multi-cylinder compressors, lubricating oil can also be used to control the unloading mechanism.

Related Articles

- Have You Encountered the Three Common Problems of Refrigeration Compressors?

- How to Calculate Refrigeration Load? And What Are the Issues?

- What to Do if the Compressor of a Frozen and Refrigerated Display Cabinet Runs but the Refrigeration Effect Is Poor?

- Instructions for Welding and Drainage in the Installation of Refrigeration Equipment Pipelines

- Common Pressure Valves and Protection Devices in Refrigeration Units

- Precautions for Using Rotary Refrigeration Compressors

- What Misconceptions Should Be Avoided in Low - temperature Refrigeration System Repairs

- Essential for Maintenance! Parameters and Phenomena of Normal Operation of Refrigeration and Heating Systems

- Composition and Common Faults of Screw Refrigeration Compressors

- How to Read the High - and Low - Pressure Gauges of Refrigeration Air - conditioners?

- What is Cascade Refrigeration?

- Introduction to Control Valves in Refrigeration Systems

- Welding Equipment Used in Refrigeration System Maintenance

- Where Lie the Key Construction Technologies of the Ammonia Refrigeration System?

- What to Do When a Refrigeration Unit Malfunctions?

- Could a Tiny Copper Tube Cause a Multi - split Air Conditioner to Stop Cooling? Refrigeration Workers Must Pay Attention!

- Has Your Refrigeration System Experienced "Oil Carry - over"?

- Basic Knowledge of Valve - type Components in Refrigeration Systems (Technical Sharing)