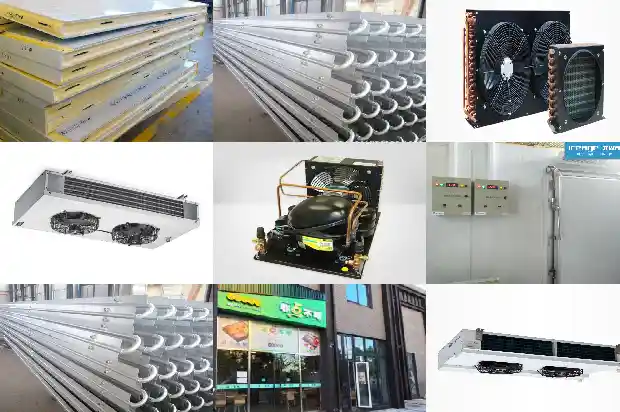

Refrigeration System Components and Common Failures

2024-09-17

I. Functions of Common Components in Cold Storage System

- Compressor: It plays the role of compressing and driving the refrigerant in the refrigerant circuit and is the power source of the refrigeration system.

- Condenser: It is one of the main heat exchange equipments in the cold storage refrigeration system. Its function is to cool and condense the superheated vapor of high-temperature refrigerant discharged by the assembled cold storage compressor into high-pressure liquid.

- Evaporator: It makes the liquid refrigerant evaporate at low pressure and low temperature, absorbs the heat transmitted from the freezer and evaporates to become gaseous refrigerant.

The gaseous refrigerant is sucked in by the compressor for compression and then discharged into the condenser for heat dissipation. Basically, the principle of the evaporator is the same as that of the condenser. The difference is that the former absorbs heat from the warehouse while the latter dissipates heat to the outside.

- Liquid storage tank: It stores the Freon storage tank to ensure that the refrigerant is always in a saturated state.

- Solenoid valve: Firstly, it prevents the refrigerant liquid in the high-pressure part from entering the evaporator when the compressor stops, avoids excessive low pressure when the compressor starts next time, and prevents liquid hammer of the compressor. Secondly, when the temperature of the cold storage reaches the set value, the temperature controller acts, the solenoid valve loses power. When the low-pressure pressure reaches the shutdown set value, the compressor stops. When the temperature in the cold storage rises back to the set value, the temperature controller acts, the solenoid valve is energized, and when the low-pressure pressure rises to the compressor startup set value, the compressor starts.

- High and low pressure protector: It prevents the compressor from being damaged by excessive high pressure and too low pressure.

- Temperature controller: Equivalent to the brain of the cold storage, it controls the start and stop of refrigeration in the cold storage, as well as the start and stop of defrosting and fans.

- Drying filter: It filters impurities and moisture in the system.

- Oil pressure protector: It ensures that the compressor has enough lubricating oil.

- Expansion valve: It makes the high-pressure refrigeration liquid at the outlet of the expansion valve expand and evaporate rapidly, absorb the heat in the air through the pipe wall, and conduct heat exchange.

- Oil separator: Its function is to separate the lubricating oil in the high-pressure steam discharged by the refrigeration compressor to ensure the safe and efficient operation of the device. According to the oil separation principle of reducing air flow velocity and changing air flow direction, the oil particles in high-pressure steam can be separated under the action of gravity. Generally, when the air flow velocity is below 1m/s, oil particles with a diameter of more than 0.2mm contained in the steam can be separated. Commonly used oil separators are of four types: washing type, centrifugal type, packing type and filtering type.

- Evaporator pressure regulating valve: It is to prevent the evaporator pressure (and evaporation temperature) from dropping below the specified value. Sometimes it is also used to adjust the evaporator pressure to adapt to load changes.

- Fan speed regulator: This series of fan speed regulators are mainly used for speed regulation of fan motors of outdoor air-cooled condensers of refrigeration equipment or for speed regulation of cooling fans of cold storages.

II. Common Faults of Cold Storage Equipment

- Refrigerant leakage: After refrigerant leakage in the system, the cooling capacity is insufficient, the suction and exhaust pressures are low, and a much louder intermittent "squeaking" air flow sound than usual can be heard at the expansion valve. The evaporator does not frost or has a small amount of floating frost. If the expansion valve hole is enlarged, there is still no significant change in the suction pressure. After shutdown, the equilibrium pressure in the system is generally lower than the saturation pressure corresponding to the same ambient temperature.

- Excessive refrigerant charging after maintenance: In the refrigeration system after maintenance, the amount of refrigerant charged exceeds the capacity of the system. The refrigerant will occupy a certain volume of the condenser, reducing the heat dissipation area and reducing its cooling effect. The suction and exhaust pressures are generally higher than the normal pressure values. The evaporator does not frost firmly, and the temperature drop in the warehouse is slow.

- Air in the refrigeration system: Air in the refrigeration system will reduce the refrigeration efficiency. The obvious phenomenon is that the suction and exhaust pressures increase (but the exhaust pressure has not exceeded the rated value). The temperature from the compressor outlet to the condenser inlet increases significantly. Due to the presence of air in the system, the exhaust pressure and exhaust temperature both increase.

- Low efficiency of compressor: Low efficiency of refrigeration compressor refers to the corresponding reduction in cooling capacity due to the decrease in actual displacement under unchanged working conditions. This phenomenon mostly occurs on compressors that have been used for a long time. They are worn out, the fitting clearances of various components are large, and the sealing performance of gas valves decreases, resulting in a decrease in actual displacement.

- Excessive frost on the surface of the evaporator: The evaporator of a long-term used cold storage should be defrosted regularly. If not defrosted, the frost layer on the evaporator pipeline will accumulate thicker and thicker. When the entire pipeline is covered by a transparent ice layer, the heat transfer will be seriously affected, so that the temperature in the warehouse cannot fall within the required range.

- There is refrigeration oil in the evaporator pipeline: In the refrigeration cycle process, some refrigeration oil remains in the evaporator pipeline. After a long period of use, when there is more residual oil in the evaporator, it will seriously affect its heat transfer effect and cause poor refrigeration.

- The refrigeration system is not unobstructed: Due to the unclean cleaning of the refrigeration system, after a certain period of use, dirt gradually accumulates in the filter, and some mesh holes are blocked, resulting in a decrease in refrigerant flow and affecting the refrigeration effect. There are also slight blockages in the filter screens at the expansion valve and the compressor suction port in the system.

- Frozen blockage at the expansion valve hole: The main components in the refrigeration system are not properly dried, the entire system is not evacuated thoroughly, and the moisture content of the refrigerant exceeds the standard.

- Dirty blockage at the filter screen of the expansion valve: When there is more coarse powdery dirt in the system, the entire filter screen will be blocked and the refrigerant cannot pass through, resulting in no refrigeration. Knocking on the expansion valve can sometimes achieve refrigeration by passing some refrigerant. It is recommended to remove the filter for cleaning and drying and reinstall it into the system.

Related Articles

- Have You Encountered the Three Common Problems of Refrigeration Compressors?

- How to Calculate Refrigeration Load? And What Are the Issues?

- What to Do if the Compressor of a Frozen and Refrigerated Display Cabinet Runs but the Refrigeration Effect Is Poor?

- Instructions for Welding and Drainage in the Installation of Refrigeration Equipment Pipelines

- Common Pressure Valves and Protection Devices in Refrigeration Units

- Precautions for Using Rotary Refrigeration Compressors

- What Misconceptions Should Be Avoided in Low - temperature Refrigeration System Repairs

- Essential for Maintenance! Parameters and Phenomena of Normal Operation of Refrigeration and Heating Systems

- Composition and Common Faults of Screw Refrigeration Compressors

- How to Read the High - and Low - Pressure Gauges of Refrigeration Air - conditioners?

- What is Cascade Refrigeration?

- Introduction to Control Valves in Refrigeration Systems

- Welding Equipment Used in Refrigeration System Maintenance

- Where Lie the Key Construction Technologies of the Ammonia Refrigeration System?

- What to Do When a Refrigeration Unit Malfunctions?

- Could a Tiny Copper Tube Cause a Multi - split Air Conditioner to Stop Cooling? Refrigeration Workers Must Pay Attention!

- Has Your Refrigeration System Experienced "Oil Carry - over"?

- Basic Knowledge of Valve - type Components in Refrigeration Systems (Technical Sharing)