Selection Methods for Site, Capacity, Insulation Materials and Refrigeration System in Cold Storage Construction Design

2025-04-06

- Selection of the Site for Refrigerated Warehouse Design

Commonly used refrigerated warehouses can be divided into three categories: wholesale - operated refrigerated warehouses, retail - used refrigerated warehouses, and production - oriented refrigerated warehouses. Production - oriented refrigerated warehouses are built in areas where the sources of goods are relatively concentrated. Factors such as convenient transportation and connection with the market also need to be considered.

Refrigerated warehouses should not be built in places with direct sunlight and excessive temperatures.

It is best to build them in shady places. Small - sized refrigerated warehouses are preferably built indoors. There should be good drainage conditions around the refrigerated warehouse, and the groundwater level should be low. It is better to have an interlayer under the refrigerated warehouse, and keep good ventilation.

Maintaining dryness is very important for the refrigerated warehouse. In addition, before building the refrigerated warehouse, a three - phase power supply with an appropriate capacity should be installed first according to the power of the refrigeration unit of the cold storage. If the refrigeration unit of the cold storage is water - cooled, water pipes should be laid and a cooling tower should be built.

- Determination of the Storage Capacity of the Refrigerated Warehouse

The storage capacity of the refrigerated warehouse should be designed according to the maximum quantity of the stored products. This capacity is calculated and determined based on the volume required for the stacked stored products in the cold storage, plus the passageways for pedestrians, etc. Then, the length, width, and height of the cold storage are determined. - Selection of Insulation Materials for Refrigerated Warehouse

The selection of insulation materials for refrigerated warehouses should not only have good heat - insulation performance but also be economical and practical. There are several types of insulation materials for cold storage. One type is the cold - storage panels with hooks on four sides, which are processed according to the length, width, and height. The corresponding specifications of the cold - storage panels can be selected according to the installation needs of the cold - storage body. For high - and medium - temperature cold storages, 10 - centimeter - thick cold - storage panels are generally selected.

For low - temperature cold storages and freezing cold storages, 12 - centimeter or 15 - centimeter - thick cold - storage panels are generally selected. Another type of cold storage can use polyurethane spray - foaming. The material is directly sprayed onto the brick or concrete warehouse of the cold storage to be built. After shaping, it is both moisture - proof and heat - insulating.

Insulation materials include polyurethane, polystyrene, etc. Polyurethane does not absorb water and has good heat - insulation performance, but the cost is relatively high. Polystyrene has strong water - absorption and poor heat - insulation performance, but the cost is relatively low. The structure of modern cold storages is developing towards pre - fabricated cold storages. Cold - storage components including moisture - proof layers and heat - insulation layers are made and assembled on - site. Its advantages are convenient and fast construction, and it can be moved, but the cost is relatively high. - Selection of the Refrigeration System for Refrigerated Warehouse

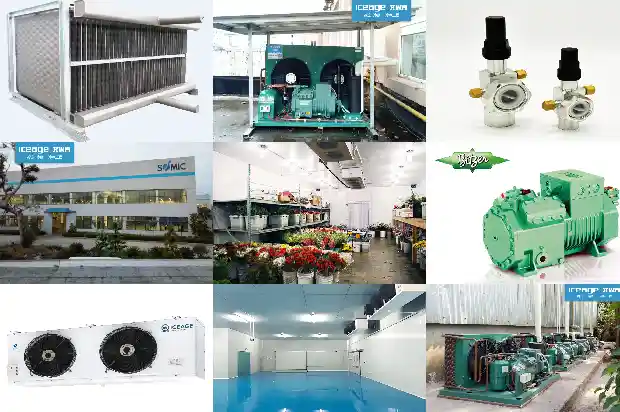

The selection of the refrigeration system for a cold storage mainly refers to the selection of the cold - storage compressor and the evaporator. Generally, fully - enclosed compressors are mainly selected for small - sized cold storages. Because fully - enclosed compressors have small power and relatively low prices. For medium - sized cold storages, semi - enclosed compressors are generally selected. For large - sized cold storages, semi - enclosed compressors are also selected. When choosing, the ammonia refrigeration compressor can also be considered. Because the ammonia refrigeration compressor has high power and can be used for multiple purposes, but the installation and management of the cold storage are relatively complex. When selecting the evaporator, air - coolers are selected as the evaporators for high - temperature cold storages. Their characteristic is that the cooling speed is fast, but it is easy to cause water loss of the refrigerated products. For medium - and low - temperature cold storages, evaporator coils made of seamless steel pipes are mainly selected. Their characteristic is that the constant - temperature effect is good and they can store cold in a timely manner.

Related Articles

- Analysis of Selection Techniques for Thermal Insulation Materials in Seafood Freezer Construction

- Common Calculations for Fan Selection

- Classification, Principle, Model Selection and Application, and Troubleshooting of Fan Coils

- Composition, Classification and Selection of Cooling Towers

- Installation Precautions and Accessory Selection for Cold Storage Unit

- Screw Compressor Units: Principles, Design and Selection - Essential Guide for Refrigeration Beginners

- Selection of Bypass Control Valves for Air - conditioning Water Systems

- Reference Points for Selection of Screw - type Chillers

- Selection and Installation of Thermal Expansion Valves

- Function and Selection of Buffer Tanks

- A Complete Guide to the Operation, Malfunctions and Repair Methods of Dry Screw Refrigeration Compressors!

- Analysis of Common Malfunctions and Treatment Methods of Cold Storage Equipment

- What Are the Daily Maintenance Methods for Controlled Atmosphere Cold Storage Equipment?

- Maintenance Methods for Screw Chiller Units

- Introduction to Energy - saving Methods of Cooling Towers

- Maintenance Methods for Exhaust Volume and Winding Performance of Typical Air - conditioner Compressors

- Liquid Supply Methods for Cold Storage Refrigeration Systems

- Common Faults and Treatment Methods of Single-phase Asynchronous Motors