What Are the Daily Maintenance Methods for Controlled Atmosphere Cold Storage Equipment?

2025-03-18

The construction cost of a controlled - atmosphere storage is relatively high. Therefore, it requires careful daily care and regular maintenance. The following maintenance plan is for reference regarding the regular maintenance of a controlled - atmosphere fresh - keeping storage.

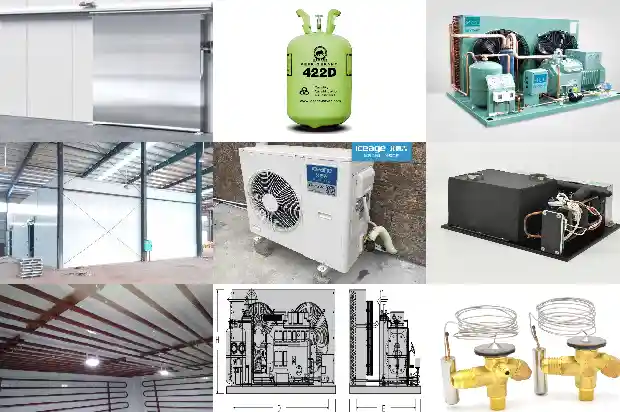

Structure of the Controlled - Atmosphere Storage

The biggest difference between a controlled - atmosphere storage and a cold storage is that the former changes the gas composition inside the storage. That is, during the long - term storage period, the storage maintains a low - oxygen and high - carbon - dioxide environment. In this environment, humans cannot survive. So, once the storage is sealed, people are not allowed to enter for work. Even with an oxygen breathing apparatus, one can only enter for a short - term in an emergency, and it is quite inconvenient. This requires the internal structure of the storage (including concealed works and in - storage facilities) to be safe and reliable, and in - storage operations during the storage period should be avoided as much as possible. The envelope structure mainly includes the walls, ceiling, and floor of the controlled - atmosphere storage, which are all key structures of the controlled - atmosphere storage. The walls and ceiling of a prefabricated controlled - atmosphere storage are self - supporting structures, and the floor is a load - bearing structure. The requirements for the walls and ceiling are mainly airtightness, heat insulation, resistance to temperature - change stress, and stability. In addition to the above requirements, the floor must also have sufficient compressive strength to withstand the static and dynamic loads generated by fruits and vegetables, packaging, shelves, equipment, forklifts, etc. The heat - insulation facilities of the controlled - atmosphere storage not only require no cold bridges or minimizing cold bridges as much as possible but also require good thermal insulation performance.

The biggest difference between a controlled - atmosphere storage and a cold storage is that the former changes the gas composition inside the storage. That is, during the long - term storage period, the storage maintains a low - oxygen and high - carbon - dioxide environment. In this environment, humans cannot survive. So, once the storage is sealed, people are not allowed to enter for work. Even with an oxygen breathing apparatus, one can only enter for a short - term in an emergency, and it is quite inconvenient. This requires the internal structure of the storage (including concealed works and in - storage facilities) to be safe and reliable, and in - storage operations during the storage period should be avoided as much as possible. The envelope structure mainly includes the walls, ceiling, and floor of the controlled - atmosphere storage, which are all key structures of the controlled - atmosphere storage. The walls and ceiling of a prefabricated controlled - atmosphere storage are self - supporting structures, and the floor is a load - bearing structure. The requirements for the walls and ceiling are mainly airtightness, heat insulation, resistance to temperature - change stress, and stability. In addition to the above requirements, the floor must also have sufficient compressive strength to withstand the static and dynamic loads generated by fruits and vegetables, packaging, shelves, equipment, forklifts, etc. The heat - insulation facilities of the controlled - atmosphere storage not only require no cold bridges or minimizing cold bridges as much as possible but also require good thermal insulation performance.

Airtightness

A controlled - atmosphere storage must have good airtightness. If the airtightness does not meet certain indicators, it is impossible to form a controlled - atmosphere environment. The airtightness of a controlled - atmosphere storage is achieved by air - tight materials. The air - tight layer is a unique structural layer of the controlled - atmosphere storage and is usually a difficult problem in the construction of a controlled - atmosphere storage. The air - tight performance of the air - tight layer directly affects the adjustment and variation range of the gas composition inside the storage, and of course, also affects the storage quality of fruits and vegetables, and even the success or failure of controlled - atmosphere storage. The focus of storage management is the detection and leakage - repair of the airtightness of the envelope structure.

A controlled - atmosphere storage must have good airtightness. If the airtightness does not meet certain indicators, it is impossible to form a controlled - atmosphere environment. The airtightness of a controlled - atmosphere storage is achieved by air - tight materials. The air - tight layer is a unique structural layer of the controlled - atmosphere storage and is usually a difficult problem in the construction of a controlled - atmosphere storage. The air - tight performance of the air - tight layer directly affects the adjustment and variation range of the gas composition inside the storage, and of course, also affects the storage quality of fruits and vegetables, and even the success or failure of controlled - atmosphere storage. The focus of storage management is the detection and leakage - repair of the airtightness of the envelope structure.

Safety Management

Safety management includes many aspects such as equipment safety management, water - electricity and fire - prevention safety management, storage - body safety management, and personal safety management. Here, special emphasis is placed on the safety of the storage body and personal safety. The operation of a controlled - atmosphere storage is a high - risk technological operation. The staff of the controlled - atmosphere storage must participate in the study of relevant safety regulations and effectively master the safe operation techniques.

Safety management includes many aspects such as equipment safety management, water - electricity and fire - prevention safety management, storage - body safety management, and personal safety management. Here, special emphasis is placed on the safety of the storage body and personal safety. The operation of a controlled - atmosphere storage is a high - risk technological operation. The staff of the controlled - atmosphere storage must participate in the study of relevant safety regulations and effectively master the safe operation techniques.

- Storage - Body Safety

Since a controlled - atmosphere storage is a building with special requirements for airtightness, the temperature changes inside and outside the storage and during the controlled - atmosphere process may cause a pressure difference on both sides of the envelope structure.

Although safety devices such as safety valves and gas - storage bags are considered in the controlled - atmosphere storage, if management is not strengthened, it may affect the use of the controlled - atmosphere storage and even cause damage to the envelope structure. During the operation of the controlled - atmosphere storage, a certain water - column liquid level should always be maintained inside the safety valve. Considering that the outdoor temperature drops below 0℃ during winter operation, anti - freezing measures should be taken. Salts can be added to the water, and if possible, automotive antifreeze can also be added to prevent the water in the safety valve from freezing into ice. In addition to waterproofing, anti - freezing, and fire - prevention, the focus is on preventing the temperature - change effect. During the cooling test - run of the storage body, it is absolutely not allowed to close and seal the storage. Because if the storage is sealed too early, the temperature and pressure inside the storage will drop suddenly, inevitably increasing the internal - external pressure difference. When this pressure difference reaches a certain limit, it will cause the storage body to crack, making storage impossible. The correct approach is to close the storage door and carry out normal controlled - atmosphere operations after the storage temperature has stabilized within the rated range.

- Personal Safety

The personal safety mentioned here refers to the safe operation of entering and exiting the controlled - atmosphere storage. Operation and maintenance personnel must understand that the gas inside the controlled - atmosphere storage cannot sustain human life. When people enter the controlled - atmosphere storage to work, it can lead to suffocation and death. Therefore, they should understand the symptoms of suffocation and know the degree of danger of different symptoms.

Related Articles

- Maintenance Methods for Screw Chiller Units

- York Propane Compressor Maintenance, Overhaul, Upgrade and Retrofit Services

- Four Key Steps in the Refrigeration Unit Maintenance Manual!

- Common Faults and Solutions in Cold Storage Maintenance

- Maintenance Methods for Exhaust Volume and Winding Performance of Typical Air - conditioner Compressors

- Basic Knowledge of Cold Storage Maintenance

- Comprehensive Guide to the Operation and Maintenance of Cold Storage

- Common Faults and Daily Maintenance of Commercial Ice Makers

- The Use and Common Maintenance Methods of Refrigeration Compressors

- Working Principle and Daily Maintenance of Water-based Machines

- Operation and Maintenance Process of Cooling Towers

- Refrigeration Components of Refrigeration

- Basic Faults and Preventive Maintenance of Water - cooled Units

- Essential for Maintenance! Parameters and Phenomena of Normal Operation of Refrigeration and Heating Systems

- Welding Equipment Used in Refrigeration System Maintenance

- Maintenance Methods for Small Modular Cold Storage Failures

- Maintenance Techniques for Air - conditioning Refrigeration Systems

- Maintenance Strategies for the Working Cycle and Electrical Automatic Control of Chillers